High-efficiency solid-liquid thickener

A concentrator and high-efficiency technology, applied in the field of concentrators, can solve the problems of low efficiency of sewage concentrating devices, unable to meet the needs of continuous large-scale sewage treatment, etc., and achieve the effects of low use cost, reliable operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

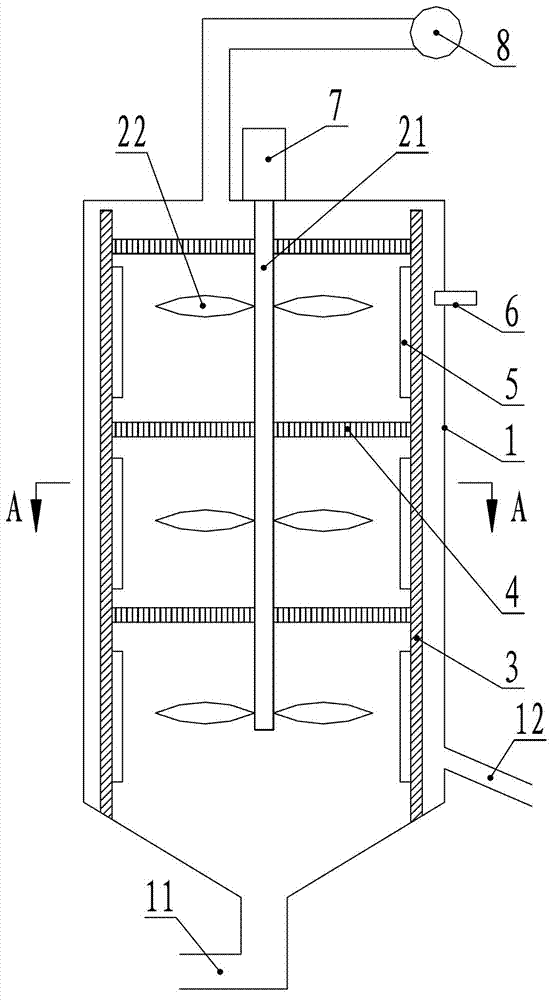

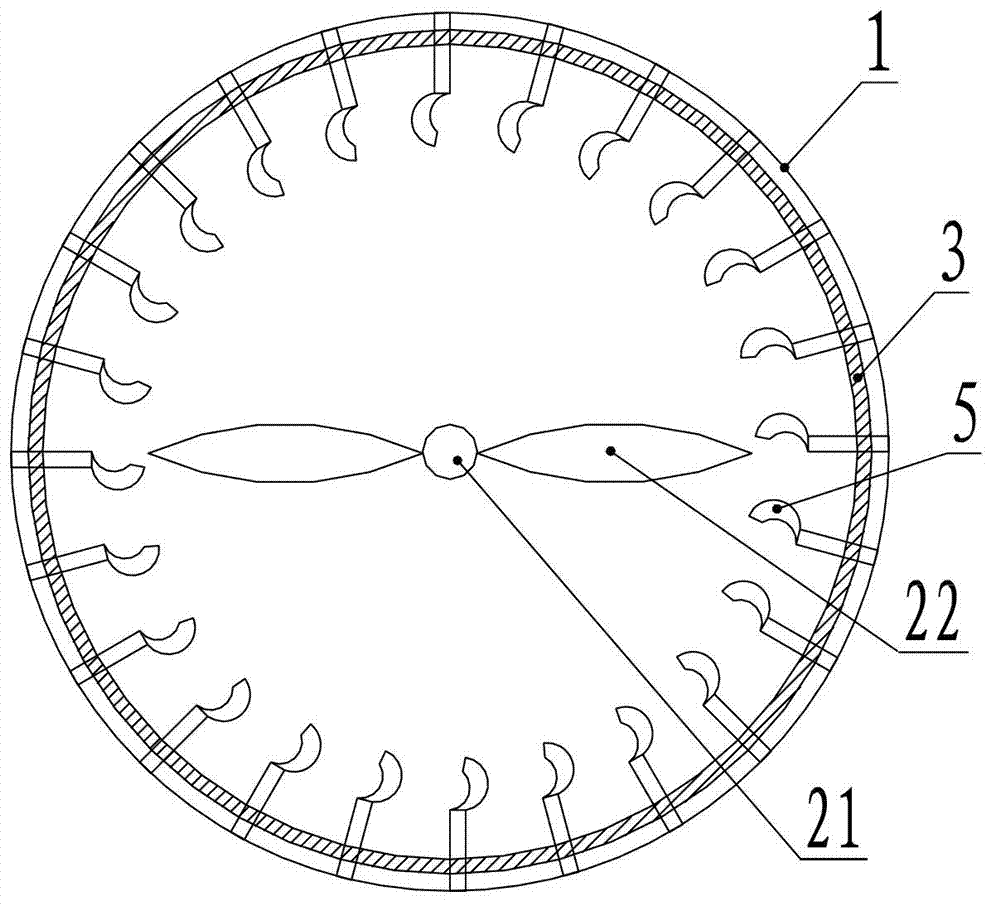

[0020] Such as Figure 1~2 As shown, the high-efficiency solid-liquid concentrator of the present embodiment includes a container 1, an agitator, a filter medium 3 and a slow flow member 4, and the agitator includes a stirring shaft 21 and a stirring paddle 22 arranged on the stirring shaft 21, and the stirring The device extends into the container 1, the filter medium 3 is arranged on the side wall of the container 1, and there is a certain gap between the side wall of the container 1, and the bottom of the container 1 is provided with a solid-liquid filter for discharging the concentrated solid-liquid mixture. The concentrate discharge port 11, the side wall of the container 1 is also provided with a filtrate discharge port 12 for discharging the filtrate, and the slow flow member 4 is arranged in the container 1, and the space in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com