An intelligent pig automatic feeding system and feeding method

A live pig, automatic technology, applied in the field of live pig breeding, can solve the problems of malnutrition development of pigs, delayed nutrition and excess fat, affecting the quality of pigs, etc., to achieve the effects of controllable feeding process, avoidance of waste, and uniform body shape for slaughter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

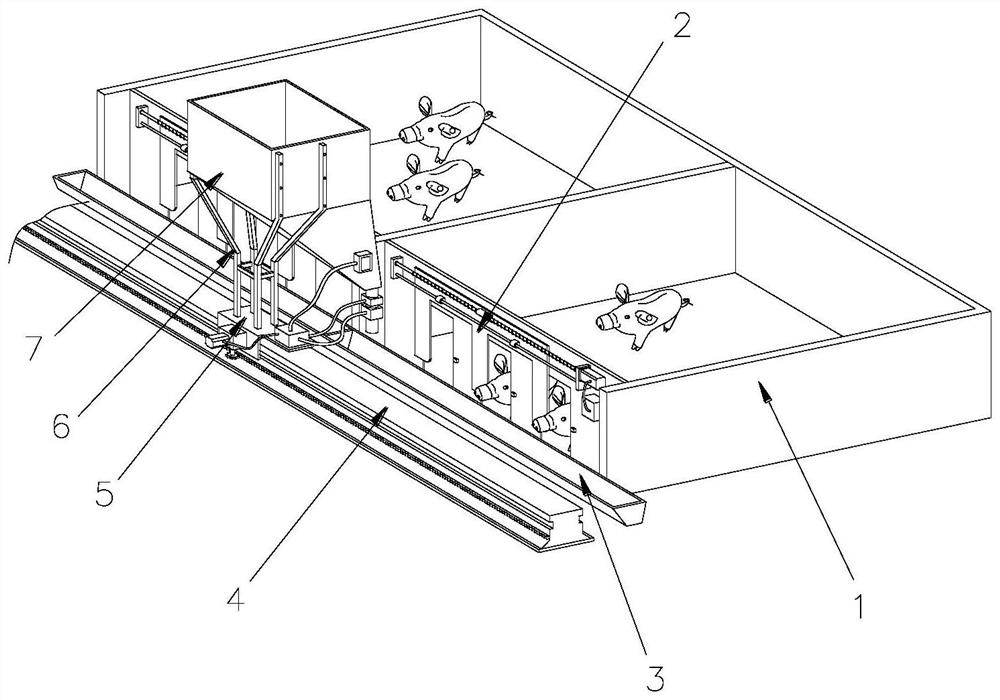

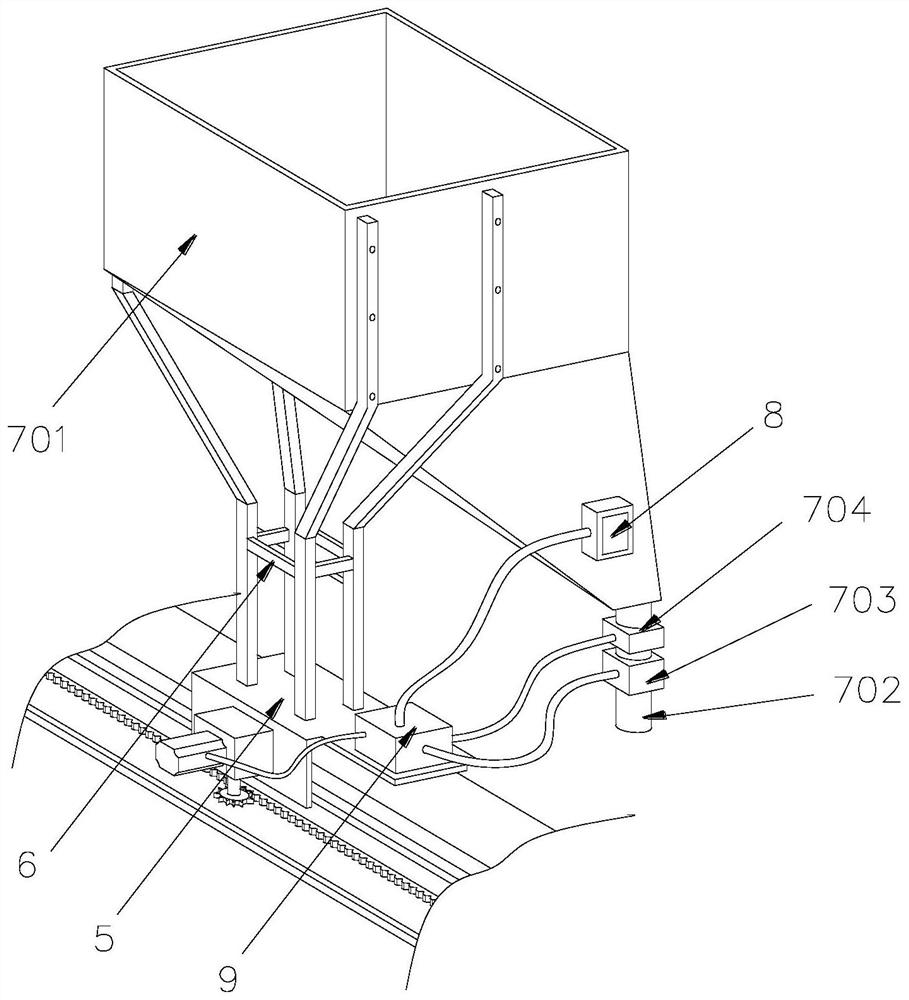

[0032] refer to figure 1 , an intelligent automatic pig breeding system, comprising feeding pens arranged in rows, three sides of the feeding pens are enclosure walls 1, one side is a guardrail 2, and a tunnel 202 for the head of a live pig to pass is arranged on the guardrail 2, and on the guardrail 2 The outer side of the feeding pen is provided with a food trough 3 along the arrangement direction of the feeding pen. The food trough 3 is used to hold pig feed. A guide rail 4 parallel to the food trough 3 is arranged on the outer side of the food trough 3. A sliding mechanism is installed on the guide rail 4. 5. A feeding device 7 is provided above the sliding mechanism 5 .

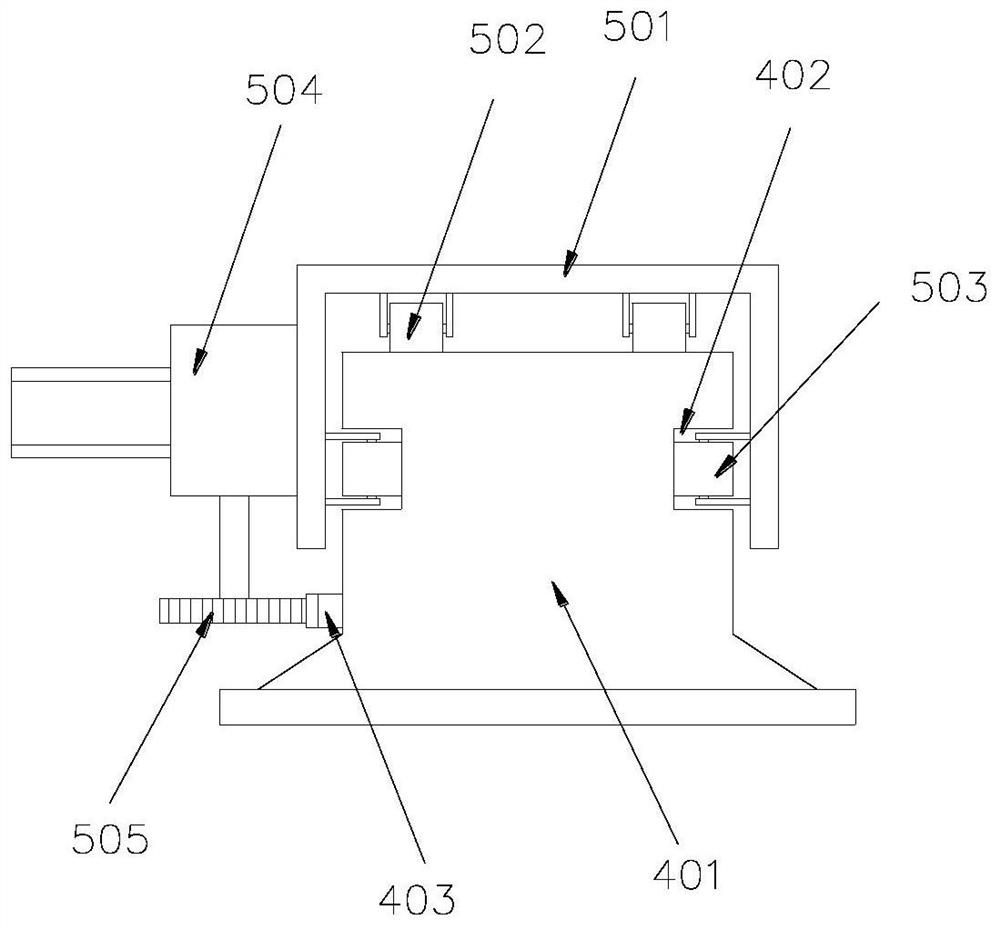

[0033] refer to figure 2 The guide rail 4 includes a rail body 401, on both sides of the rail body 401 there are guide grooves 402 symmetrically along the length direction of the rail body 401, and on one side of the rail body 401, a rack parallel to the guide groove 402 is also provided 403. The sli...

Embodiment 2

[0042] An intelligent method for automatically raising pigs, comprising the following steps:

[0043] S1, establish the standard data of feeding amount of pigs in each feeding stage, and establish the travel data of each feeding trough 3;

[0044] For a breed of pigs, the feeding cycle can be determined by feeding a specific feed. Throughout the feeding cycle, pigs continue to grow in size and require more and more feed. In each feeding stage, the feeding amount of each pig can be standardized. For example, the feeding amount within one month is N1; the feeding amount between one month and two months is N2; the feeding amount between two months and three months is N3... In this way, the standard data of feeding amount can be obtained. Food intake standard data is stored in the storage module of the control host 9; it is also necessary to calculate the stroke data of the sliding mechanism 5 according to the midpoint coordinate positions of each feeding trough 3, so as to ensu...

Embodiment 3

[0058] Considering that pigs can only eat at the holes 202, the feed in the area between two adjacent holes 202 in the trough 3 may not be eaten by pigs, resulting in waste of feed.

[0059] In order to avoid the above situation, if Figure 7 In the shown embodiment, a plurality of slots 302 are provided in the food trough 3, and an arc-shaped drainage part 303 is arranged between two slots 302, and the distance between two adjacent slots 302 is equal to the distance between the channels 202 . The drainage part 303 can drain the feed between the troughs 302 into the troughs 302 to ensure that the feed in the trough 3 can be fully eaten by the pigs and avoid waste of feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com