Integrally molded multi-light transmission sheet, integrally molded multi-light transmission sheet connector and method for manufacturing the same

A manufacturing method and technology of optical transmission, applied in the direction of optical waveguide light guide, instrument, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

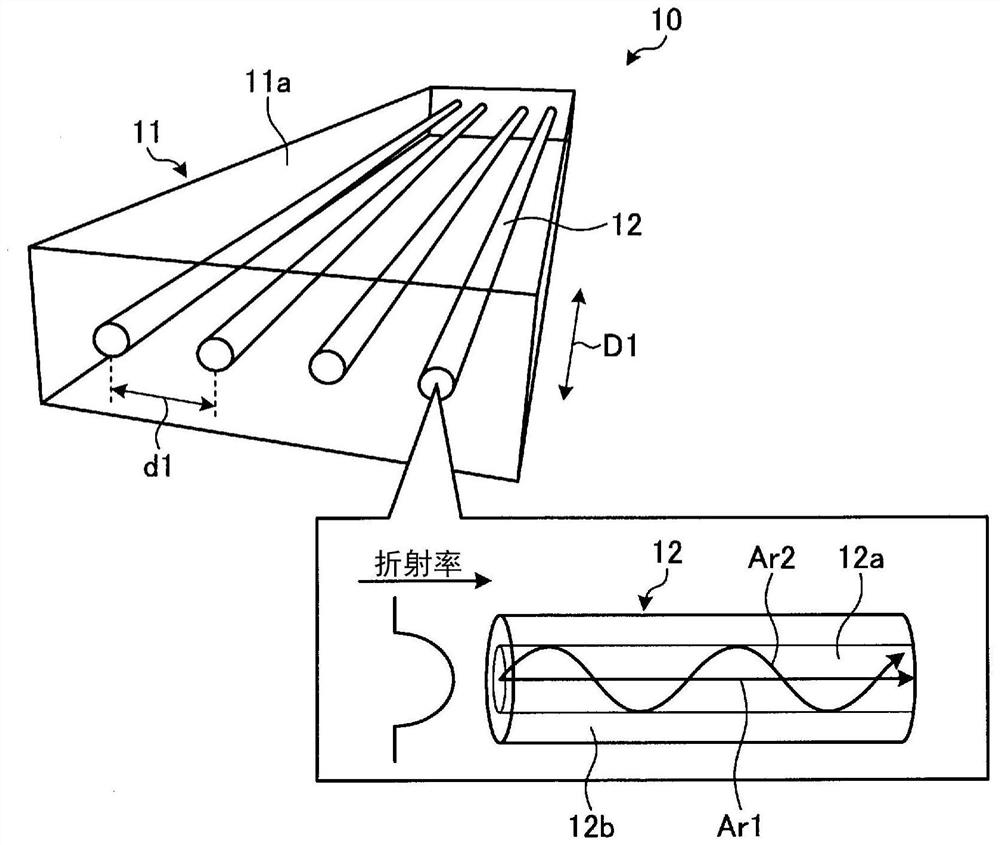

[0047] figure 1 It is a schematic diagram of the integrally molded multi-light transmission sheet concerning Embodiment 1. The integrally molded multi-light transmission sheet 10 includes: a cover portion 11 ; and a plurality of light transmission regions 12 provided inside the cover portion 11 . figure 1 The integrally formed multi-light transmission sheet 10 has four cores, and the number of light transmission areas 12 is four, but the number of light transmission areas 12 is not particularly limited. In addition, in the integrally molded multi-light transmission sheet 10, all the light transmission regions 12 have the same structure, but the present invention is not necessarily limited thereto, and one or more may be different from the others.

[0048]The covering portion 11 is made of plastic, has a sheet shape, and extends in the extending direction D1. The light transmission regions 12 extend in the diffractive extension direction D1 , and are arranged parallel to each...

Embodiment approach 2、3、4

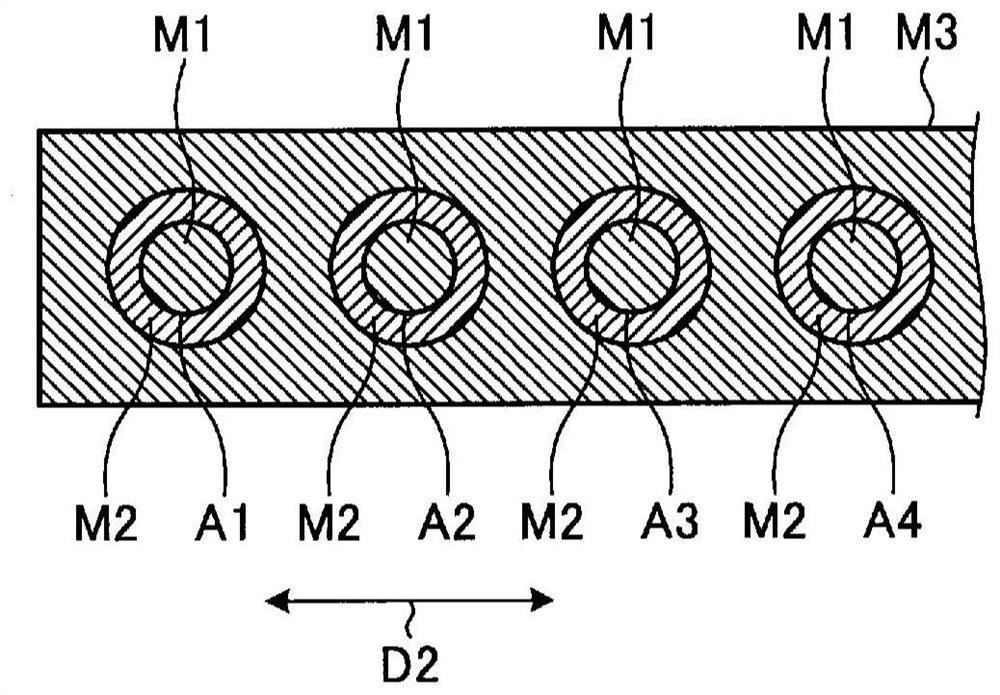

[0066] Figure 6A , 6B , 6C are schematic diagrams of the integrally molded multi-light transmission sheet according to Embodiments 2, 3, and 4. Each of the integrally molded multi-light transmission sheets 10A, 10B, and 10C includes: a covering portion 11 ; and a plurality of light transmission regions 12 provided inside the covering portion 11 . Since both the covering part 11 and the light transmission region 12 have the same structure as the corresponding elements of the integrally molded multi-light transmission sheet 10, description thereof will be omitted.

[0067] In the integrally molded multi-light transmission sheet 10A, eight light transmission regions 12 are arranged in a row. In the integrally molded multi-light transmission sheet 10B, a structure in which four light transmission regions 12 are arranged in a row is stacked in three layers.

[0068] Both the integrally molded multi-light transmission sheets 10A and 10B are similar to the integrally molded multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com