Porous self-supporting PEDOT: PSS conductive film and preparation method thereof

A conductive film, self-supporting technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as restricting applications, and achieve the effect of simple and feasible solution, high conductivity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

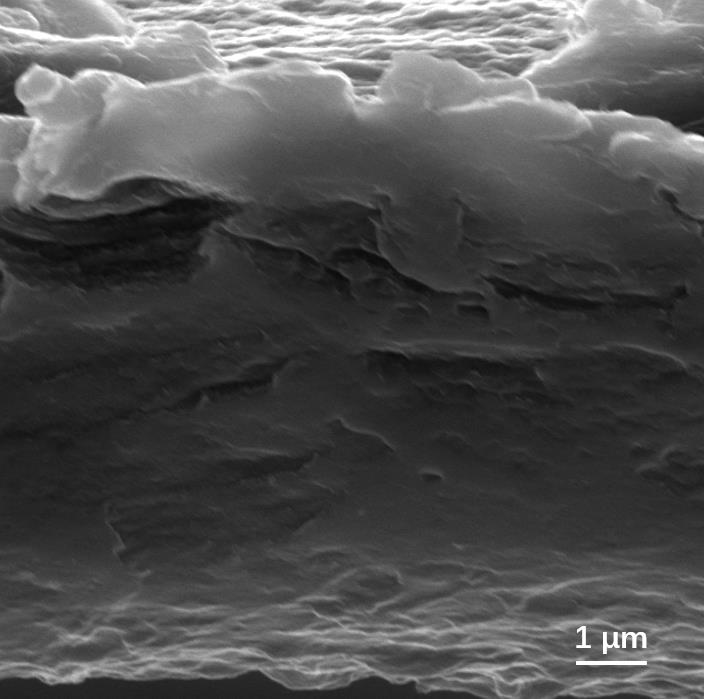

[0034] A kind of preparation method of porous self-supporting PEDOT:PSS conductive film, comprises the steps:

[0035] (1) Take 1mg of SiO with a diameter of 100-300nm 2 Nanoparticles were dispersed in 2mL deionized water, stirred and dispersed evenly to obtain SiO 2 Dispersions;

[0036] (2) Select PH1000 as the PEDOT:PSS aqueous solution, take 20 μL of SiO 2 Add the dispersion to 1mL PEDOT:PSS aqueous solution, stir for 24h to obtain PEDOT:PSS / SiO 2 Dispersions;

[0037] (3) Drop the above solution into 20mL of dilute sulfuric acid with a concentration of 1mol / L, observe flake-like precipitates, filter with a dust-free cloth to obtain PEDOT:PSS / SiO 2 flaky precipitates;

[0038] (4) The above PEDOT:PSS / SiO 2 Add 20mL of deionized water and stir evenly to obtain PEDOT:PSS / SiO 2 colloid;

[0039] (5) Vacuum filter the above colloid with a cellulose ester microporous filter membrane with a pore size of 0.45 μm, put it in an oven, dry it at 70°C for 30 minutes, and then ...

Embodiment 2

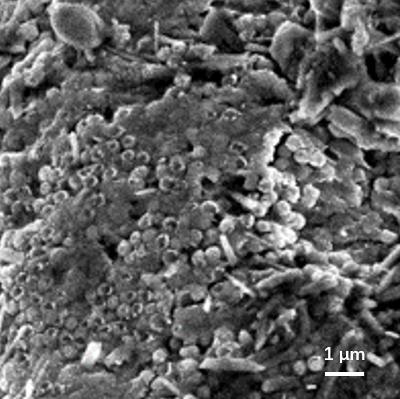

[0043] A kind of preparation method of porous self-supporting PEDOT:PSS conductive film, comprises the steps:

[0044] (1) Take 1.5mg of SiO with a diameter of 100-300nm 2 Nanoparticles were dispersed in 2mL deionized water, stirred and dispersed evenly to obtain SiO 2 Dispersions;

[0045] (2) Select PH1000 as the PEDOT:PSS aqueous solution, take 100 μL of SiO 2Add the dispersion to 1m LPEDOT:PSS aqueous solution, stir for 24h to obtain PEDOT:PSS / SiO 2 Dispersions;

[0046] (3) Drop the above solution into 20mL of dilute sulfuric acid with a concentration of 1mol / L, observe that there is a flake precipitate, filter it with a dust-free cloth, and obtain a flake PEDOT:PSS / SiO 2 ;

[0047] (4) Add the above flakes into 20mL deionized water and stir evenly to obtain PEDOT:PSS / SiO 2 colloid;

[0048] (5) Vacuum filter the above colloidal solution with a cellulose ester microporous filter membrane with a pore size of 0.45 μm, put it in an oven, dry at 70°C for 30 minutes, th...

Embodiment 3

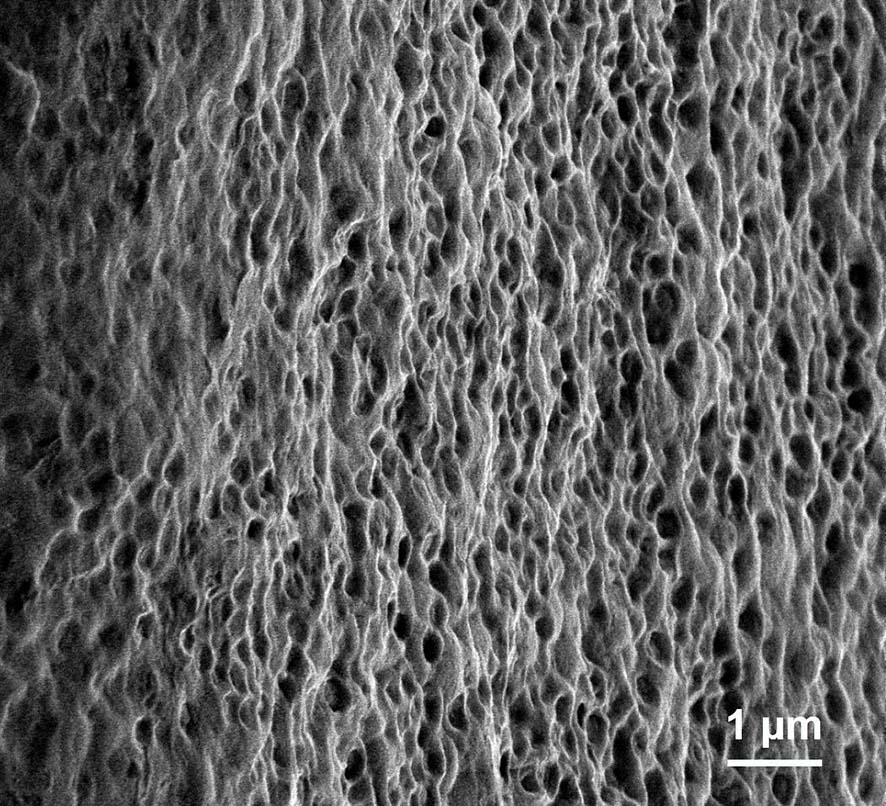

[0052] A kind of preparation method of porous self-supporting PEDOT:PSS conductive film, comprises the steps:

[0053] (1) Take 0.1mg of SiO with a diameter of 100-300nm 2 Nanoparticles were dispersed in 2mL deionized water, stirred and dispersed evenly to obtain SiO 2 Dispersions;

[0054] (2) Select PH1000 as the PEDOT:PSS aqueous solution, take 50 μL of SiO 2 The dispersion liquid was added to 1mL PEDOT:PSS aqueous solution, stirred for 24h to obtain PEDOT:PSS / SiO 2 Dispersions;

[0055] (3) Add the above solution dropwise into 20mL of dilute sulfuric acid with a concentration of 1mol / L, observe that there is flake precipitation, filter it with a dust-free cloth, and obtain the flake PEDOT:PSS / SiO 2 ;

[0056] (4) Add the above flakes into 20mL deionized water and stir evenly to obtain PEDOT:PSS / SiO 2 colloid;

[0057] (5) Vacuum filter the above colloidal solution with a cellulose ester microporous filter membrane with a pore size of 0.45 μm, put it in an oven, dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com