A Nondestructive Prediction Method for Low Cycle Fatigue Life of Thermally Aged Materials Using Hardness

A prediction method and low-cycle fatigue technology, applied in computer material science, design optimization/simulation, special data processing applications, etc., can solve problems such as no aging time and long time, and achieve simple and fast measurement, non-destructive prediction, and reduction The effect of the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0033] In this embodiment, the constant-amplitude uniaxial tension-compression strain load spectrum of cast austenitic stainless steel Z3CN20.09M, which is commonly used in nuclear power, is taken as an example under thermal aging.

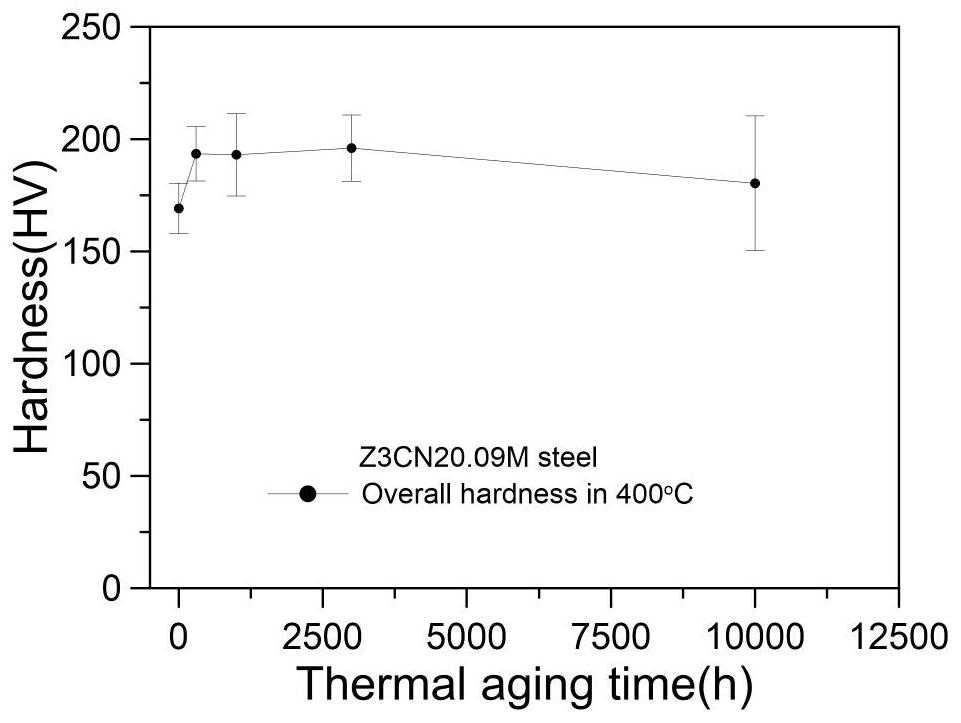

[0034] (1) Measure the strain-life curve of unaged and aged materials

[0035] The fatigue life of the material is not aged, aged for 300 hours, aged for 1000 hours, aged for 3000 hours and aged for 10000 hours, when the strain corrosion is 0.2%, 0.4%, 0.6% and 0.8%, the fatigue life changes with the thermal aging time. figure 1 As shown, the change trend of elastic strain corrosion with 2 times fatigue life is as follows figure 2 shown. It can be seen from the figure that the parameters in the Basquin-Manson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com