A Method of Evaluating the Ability of Drilling Fluid to Stabilize Borehole Wall in Shale Formation Based on Acoustic-Electric Response

A drilling fluid and mud shale technology, which is applied in the field of drilling fluid laboratory evaluation, can solve the problem of poor adaptability, inability to objectively and truly reflect the ability of the drilling fluid to stabilize the well wall, and inaccurate evaluation results in the evaluation of wellbore stability performance of mud shale formations. , reliability and other issues, to achieve the effect of density experiment test economy, avoid downhole complexity, and avoid evaluation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

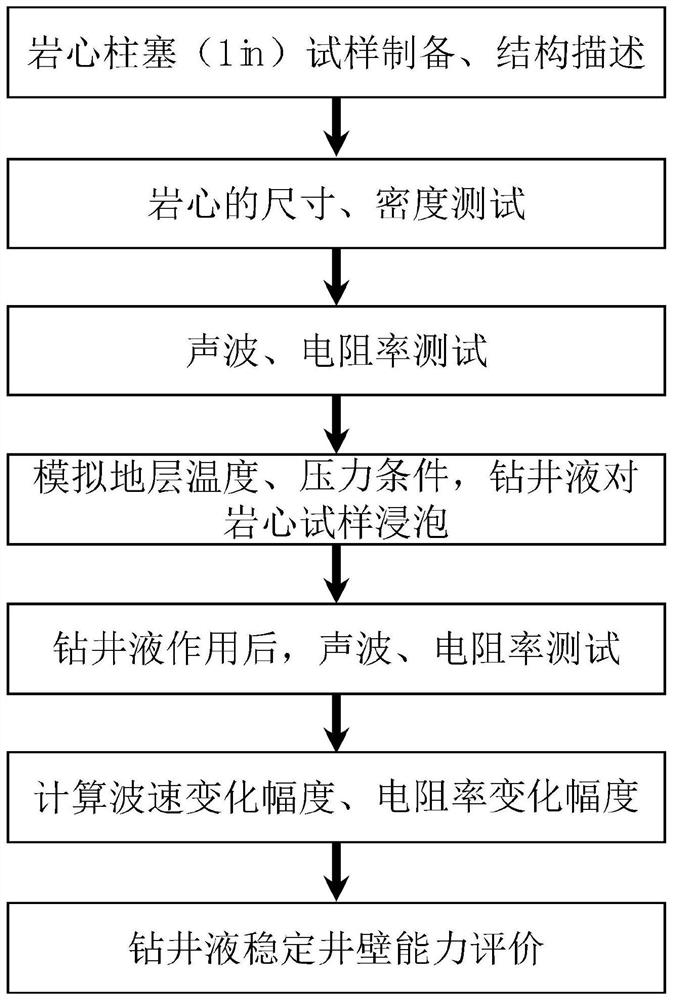

[0029] A method for evaluating the ability of drilling fluid to stabilize the borehole wall of shale formations based on acoustic-electric response, see figure 1 , the method contains:

[0030] (1) Core sample preparation

[0031] Sample drilling: drilling and coring the mud shale formation to be drilled, determining the core sample direction according to the drilling and coring direction, drilling a plunger core sample with a diameter of 1in (inch) and a length approximately twice the diameter, and a total of 5 indivual;

[0032] Sample treatment: Grind the end of the sample so that the two ends of the plunger are parallel and perpendicular to the axis, place the plunger sample in a constant temperature box, and dry it at 60°C for more than 24 hours;

[0033] Sample selection: For the drilled plunger core samples, describe the apparent structure of the samples, and select 3 core plungers with complete appearance and no obvious cracks as experimental samples, numbered C1, C2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com