Two-degree-of-freedom unequal-speed gear train transplanting mechanism and method

A technology with different degrees of freedom, applied in the field of fast-gear transplanting mechanisms, can solve the problems of accumulation of backlash, inability to accurately realize the transplanting trajectory and posture, and complex structure, so as to reduce the rate of damage and improve the efficiency of transplanting. , the effect of design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

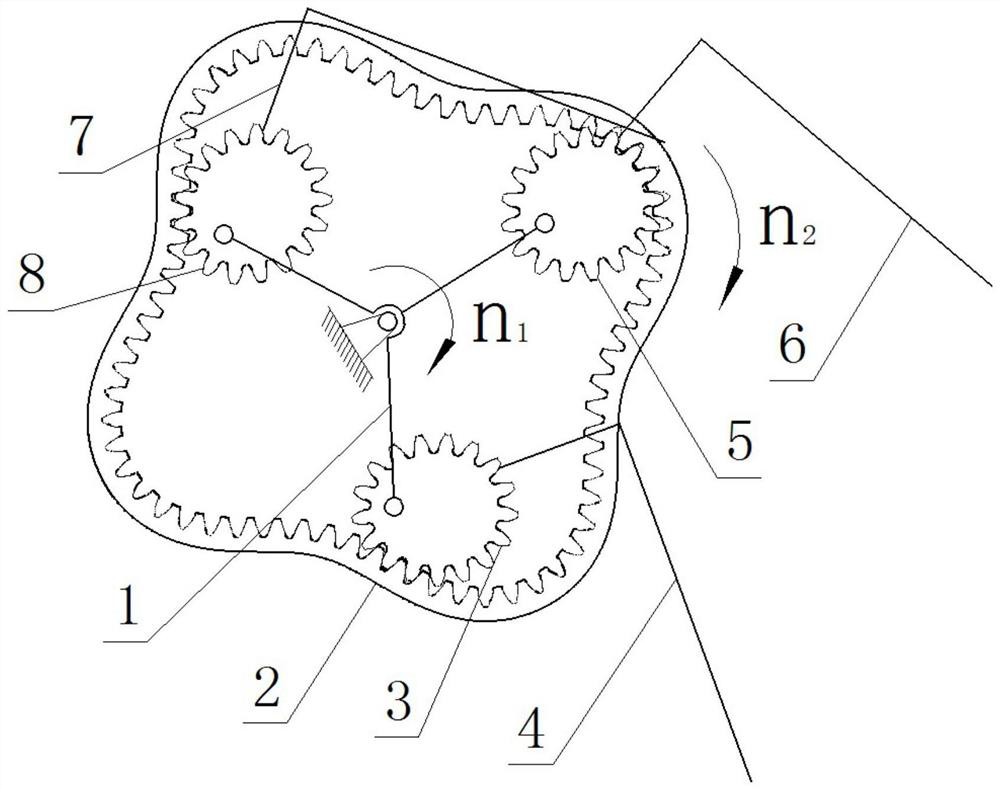

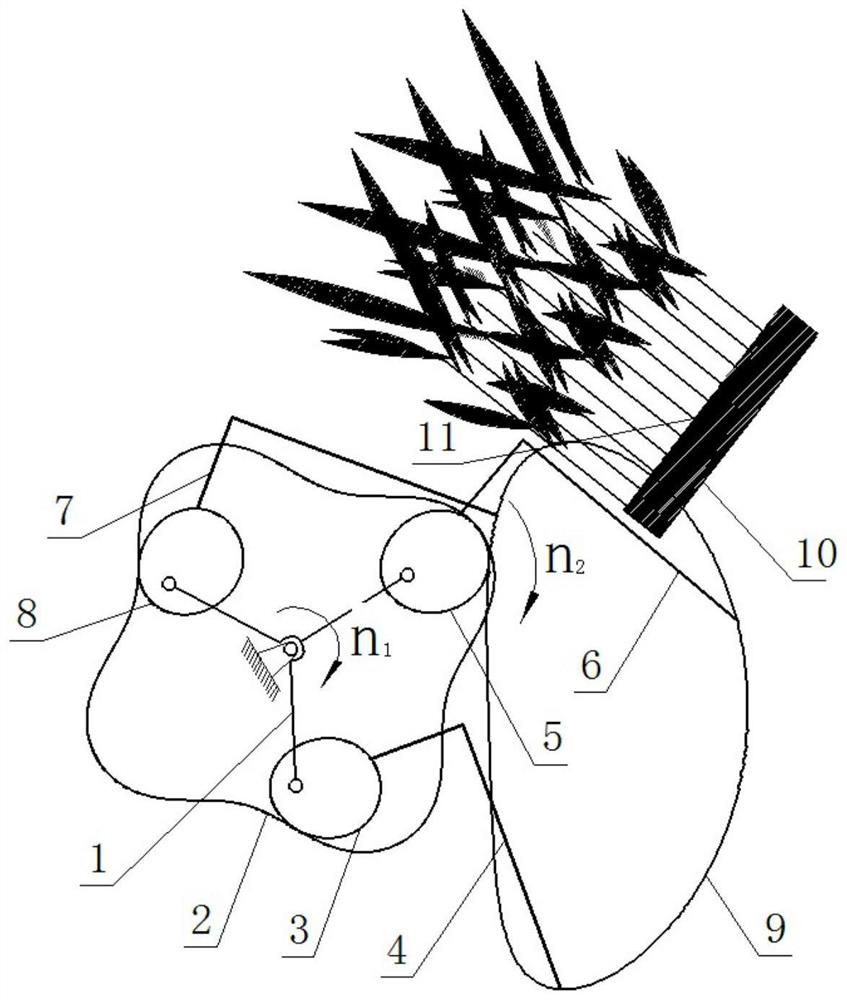

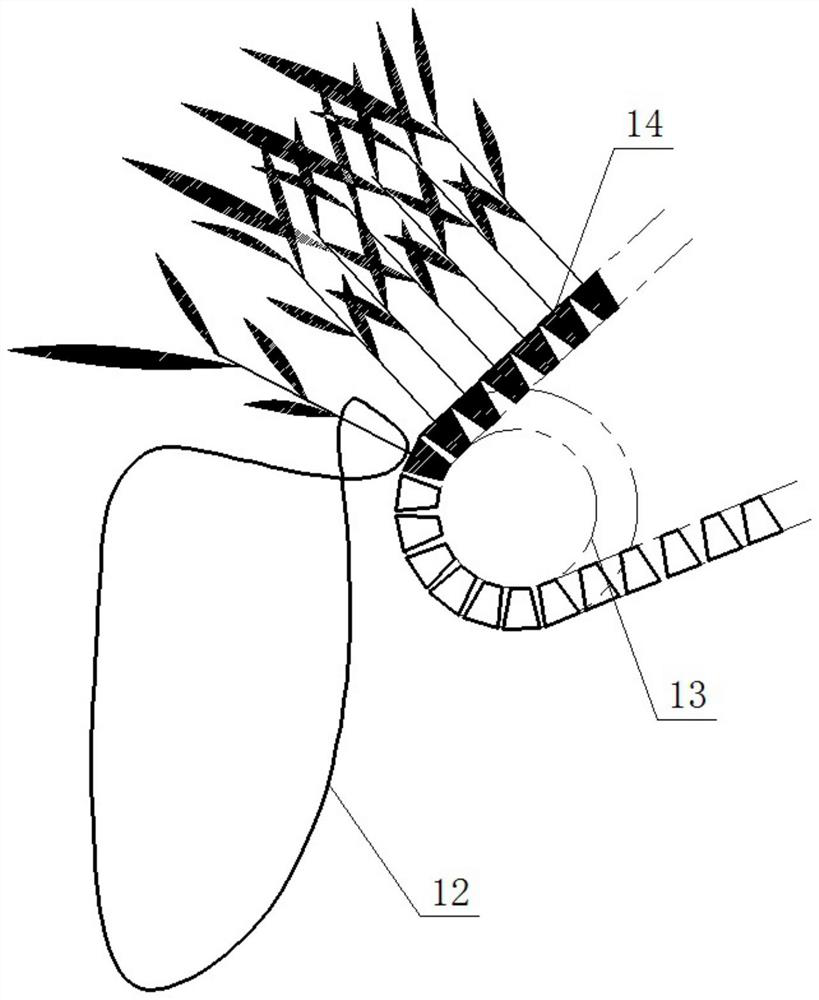

[0032] A two-degree-of-freedom non-constant velocity gear train transplanting mechanism, including a planet carrier 1, a non-circular internal gear 2, a non-circular planetary wheel I3, a planting arm I4, a non-circular planetary wheel II5, a planting arm II6, a planting arm III7 and a non-circular planetary gear II. Circular planetary gear III8; the planet carrier 1 and the non-circular internal gear 2 are coaxially hinged on the frame, and the planetary carrier 1 and the non-circular internal gear 2 rotate at the same speed of speed n1 and n2 respectively, and the non-circular planetary gear I3 , non-circular planetary gear II5 and non-circular planetary gear III8 are respectively hinged on the planet carrier 1, non-circular planetary gear I3, non-circular planetary gear II5 and non-circular planetary gear III8 mesh with non-circular intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com