Windproof and dustproof net building structure convenient to disassemble and assemble for building construction

A technology for building construction and dust-proof nets, which is applied in the field of construction of windproof and dust-proof nets for building construction, and can solve problems such as inconvenient adjustment and disassembly, poor fixing effect, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

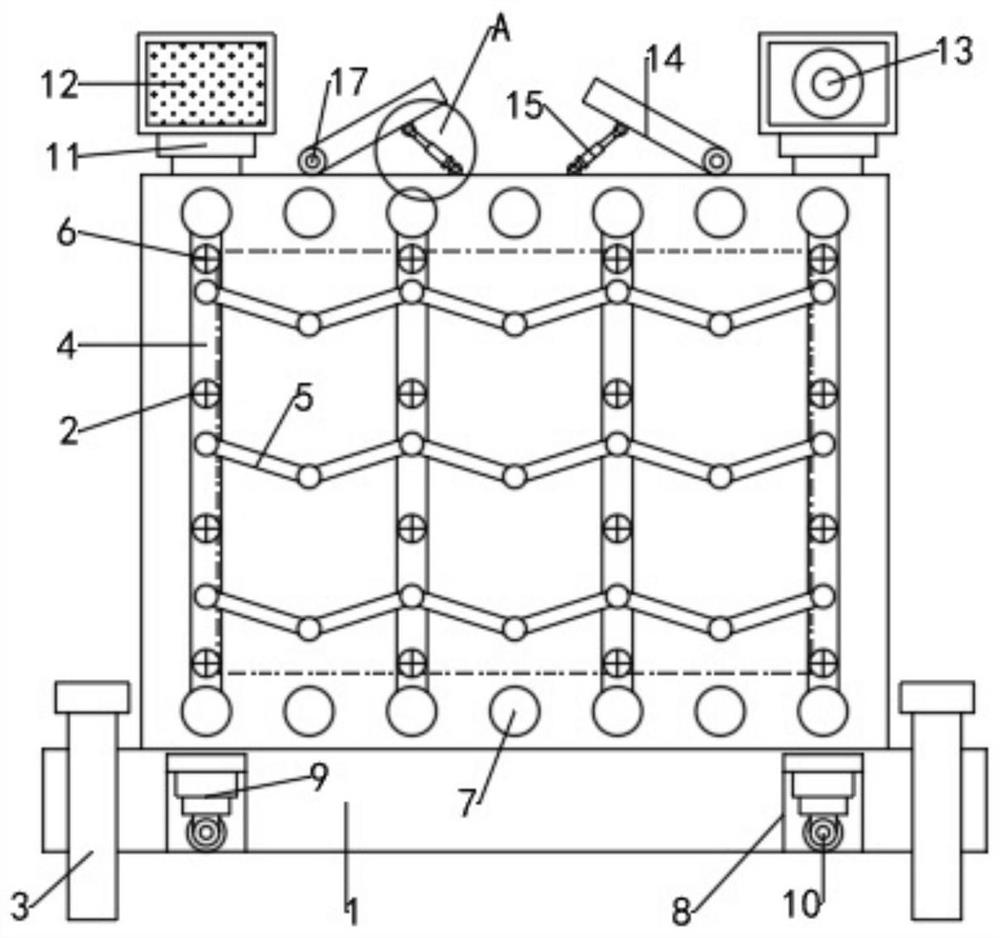

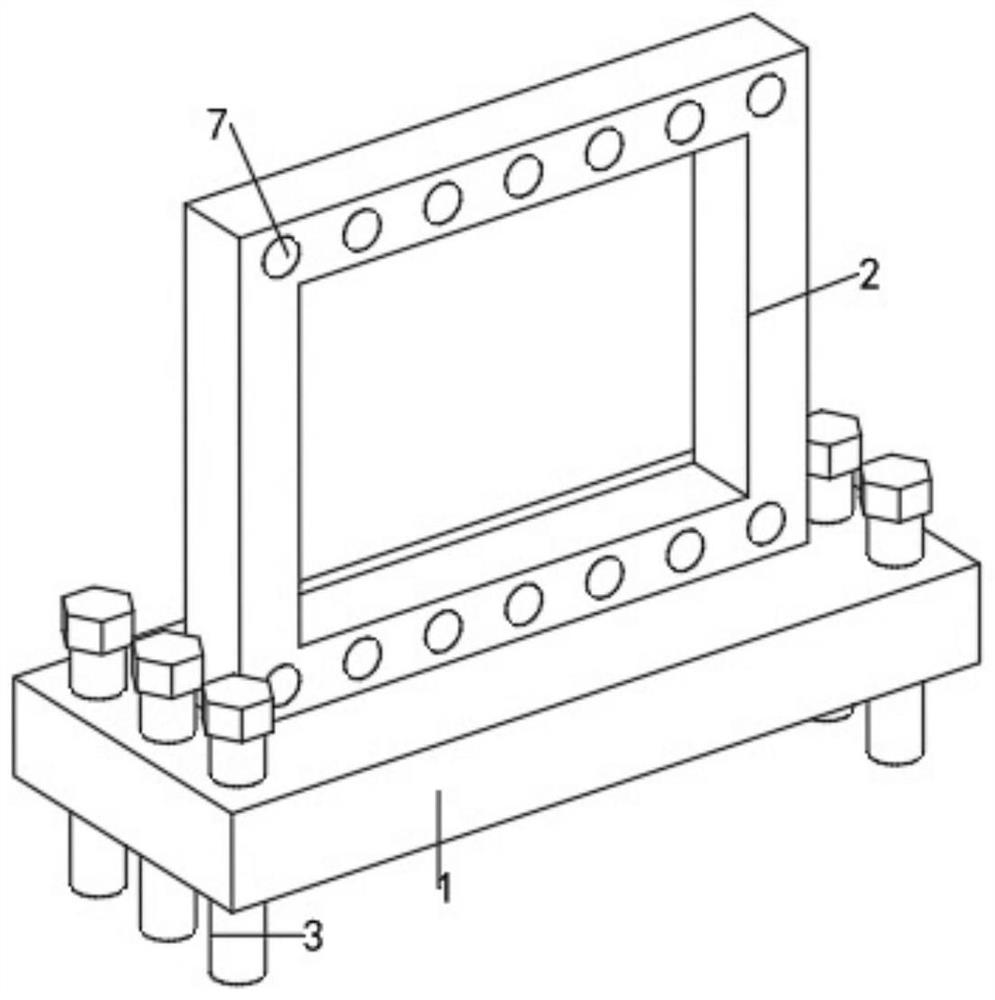

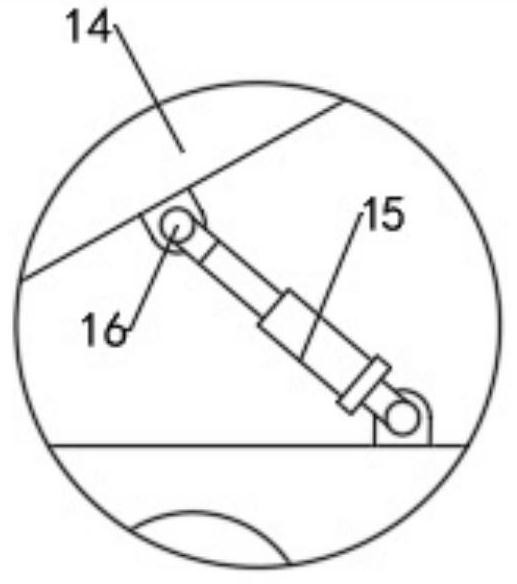

[0021] see Figure 1-5 , a windproof and dustproof mesh construction structure for building construction that is easy to disassemble and assemble, including a base 1, the upper end of the base 1 is fixedly connected with a mounting frame 2, the mounting frame 2 is a rectangular frame structure, and multiple A through assembly hole 7, the mounting frame 2 is equipped with a plurality of equidistantly distributed mounting plates 4 through the mounting holes 7, and a plurality of equidistantly distributed connecting rods 5 are rotatably connected to the mounting plate 4, and each mounting frame 2 passes through The connecting rods 5 are connected to each other; the mounting plate 4 is equidistantly arranged with a plurality of limit mechanisms 6, and the limit mechanism 6 includes assembly bolts 18, positioning nuts 19 and threaded assembly cylinders 20, and the threaded assembly cylinders 20 are arranged with Uniform internal and external threads, the threaded assembly cylinder ...

Embodiment 2

[0030] In order to prevent the warning light 12 and the recorder 13 from being unable to work normally due to immersion in water, this embodiment is improved on the basis of embodiment 1. The improvement is: the outer periphery of the warning light 12 and the recorder 13 is provided with a transparent The protective cover prevents the warning light 12 and the recorder 13 from being unable to work normally due to immersion in water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com