Underground cement-soil steel wall continuous inserting perpendicularity control construction method

A technology of cement-soil wall and construction method, which is applied in excavation, sheet pile wall, foundation structure engineering and other directions, can solve the problems of enclosure sealing, locking effect, large deviation, etc., so as to solve the problem of narrow construction space and ensure verticality control. and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

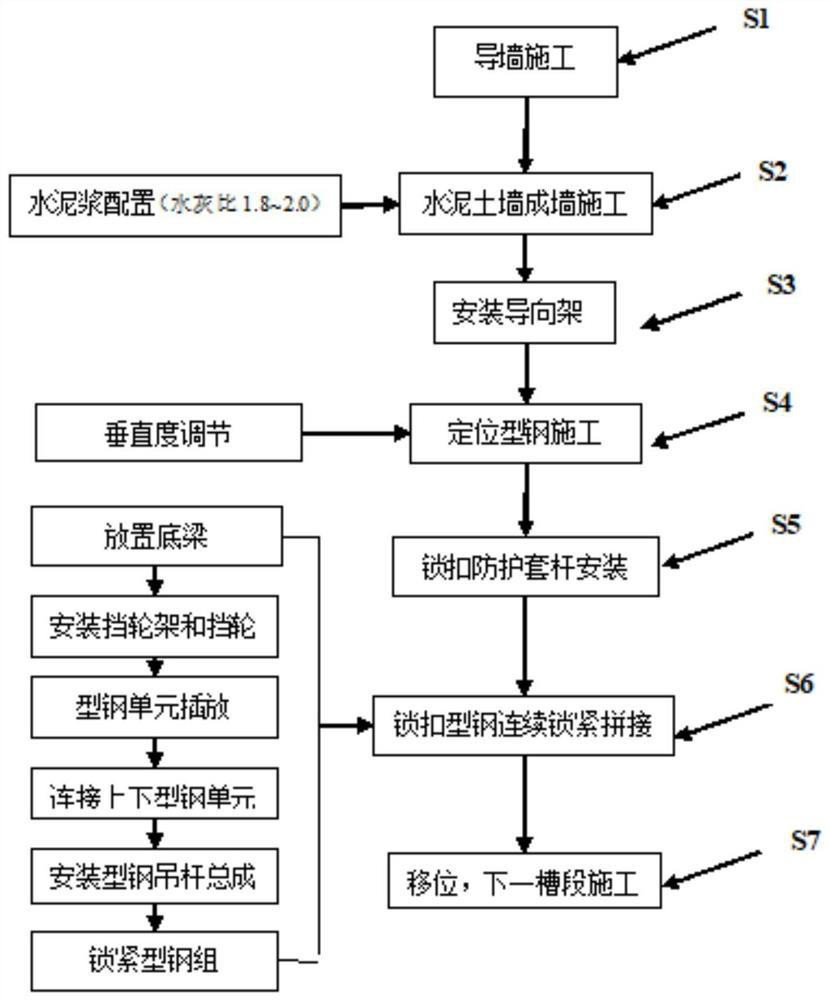

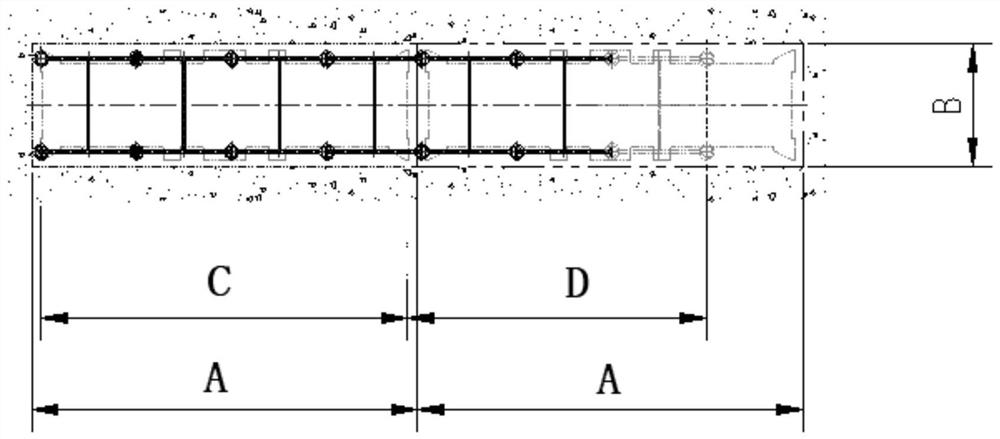

[0065] like Figure 1 to Figure 11 Shown, a kind of underground cement-soil-steel wall continuous insertion verticality control construction method, its steps are as follows:

[0066] S1: Guide wall construction: Before the construction of the underground cement-soil wall, it is advisable to build a guide wall, which is mainly used for the guidance and positioning of the underground cement-soil wall and to prevent the collapse of the groove wall. Most of the guide walls are cast-in-place reinforced concrete structures, and steel guide beams can also be used for multiple uses.

[0067] S2: Cement-soil wall construction: After the guide wall is completed, the cement-soil wall construction can be carried out, and the cement-soil wall groove can be constructed with CSM and TRD construction techniques of equal thickness cement-soil wall constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com