Highway surface marking and spraying device and using method thereof

A spraying device, road technology, applied in the direction of road surface cleaning, roads, roads, etc., can solve the problems of excessive marking, waste, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

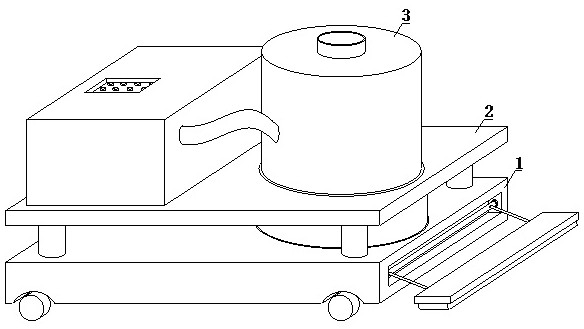

[0034] refer to figure 1 , 2 , 3, 5 and 6, a road surface marking spraying device, comprising a base plate 1, a support mechanism 2 and a barrel mechanism 3, the support mechanism 2 and the barrel mechanism 3 are all arranged on the upper surface of the base plate 1, the base plate 1 includes a connection groove 11, a pre-cleaning mechanism 12, a starting point determination module 13 and an end point calculation module 14. A connection groove 11 is opened on one side of the base plate 1, and a pre-cleaning mechanism 12 is arranged inside the connection groove 11. The bottom of the base plate 1 A starting point determination module 13 and an end point calculation module 14 are fixedly installed on the bottom surface, and the support mechanism 2 includes a support plate 21, a support rod 22 and a control box 23, and a support rod 22 is fixedly installed on the lower bottom surface of the support plate 21. The surface is provided with a control box 23, and the support plate 21 ...

Embodiment 2

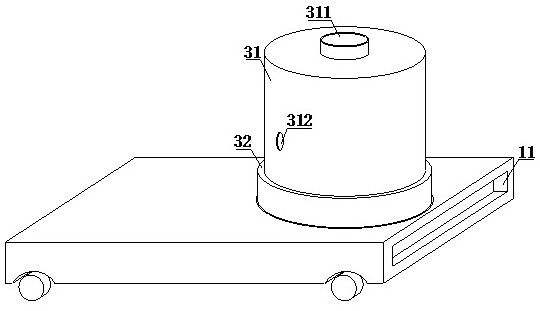

[0036] refer to figure 2 , 4 And 8, the storage tube 31 includes a feed port 311, an external interface 312, a liquid level sensing module 313, a liquid level gauge 314, a Z-shaped tube 315 and a feeding tube 316, and the upper surface of the storage tube 31 is provided with a feed port 311, The outer surface of the storage tube 31 is provided with an external interface 312, the liquid level sensing module 313 and the liquid level gauge 314 are all arranged on the inner wall of the storage tube 31, and the inside of the storage tube 31 is provided with a Z-shaped tube 315, and the bottom of the storage tube 31 The bottom surface is provided with a feeding tube 316, the storage tube 31 communicates with the spraying tube 32 through the feeding tube 316, one end of the Z-shaped tube 315 is connected with the external interface 312, and the other end of the Z-shaped tube 315 is connected with the feeding tube 316. Connected, the storage tube 31 is connected with the control box...

Embodiment 3

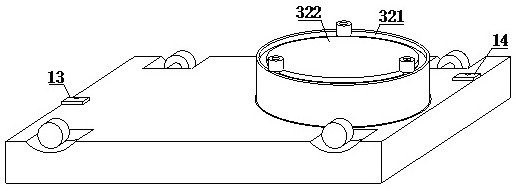

[0038] refer to Figure 5 and 8 , the control center 231 includes a distance measurement module 2311, a road surface sensing module 2312 and a speed adjustment module 2313, the distance measurement module 2311 is electrically connected with the starting point determination module 13 and the end point calculation module 14, and the starting point determination module 13 and the end point calculation module 14 are connected to the liquid level The sensing module 313 is electrically connected, and the lower bottom surface of the spraying tube 32 is provided with an arc groove 321 , and the inside of the arc groove 321 is provided with a rotating seat 322 , and the rotating seat 322 communicates with the storage barrel 31 through the feeding tube 316 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com