Electrolytic device and clothes treatment equipment

A technology of clothes treatment equipment and electrolysis device, which is applied in the direction of washing device, water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of electrolysis efficiency drop, failure, and large space occupied by electrode devices, so as to achieve extended use Effects of life, protection against contact short circuit, and improvement of design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

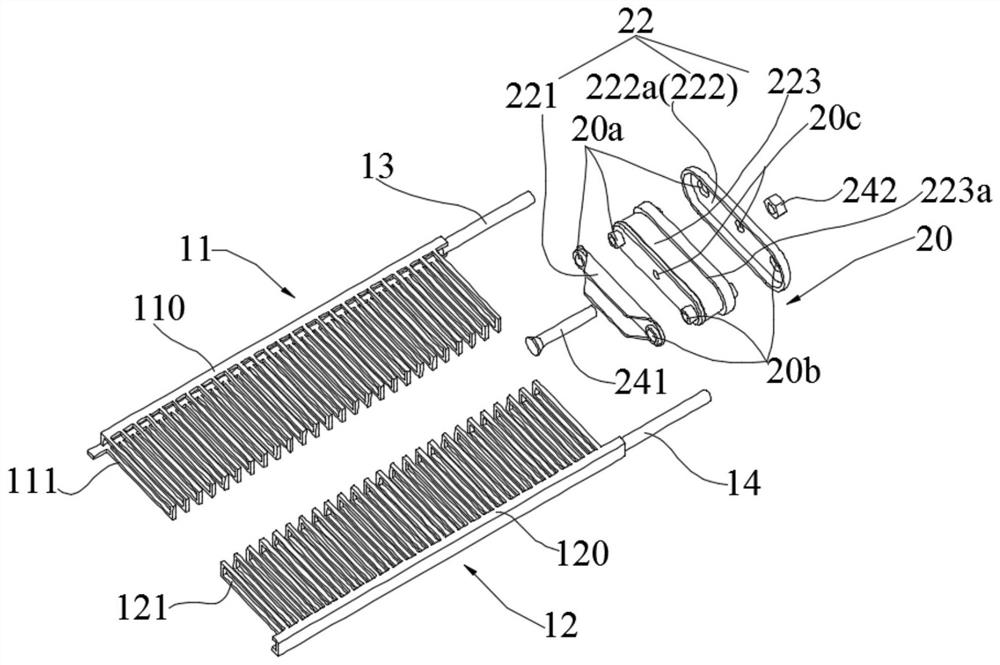

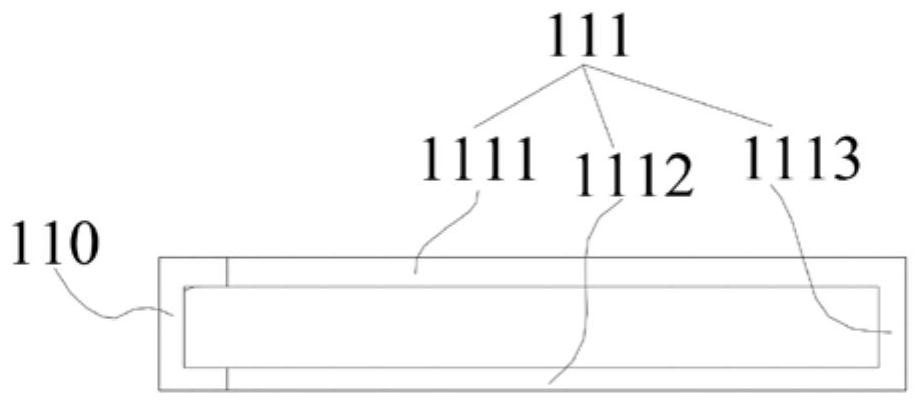

[0090] see Figure 1 to Figure 14 The extension direction of the anode conductive connector 14 and the cathode conductive connector 13 is approximately perpendicular to the plane where the first support portion 110 and the second support portion 120 are located, that is, the cathode conductive connector 13 and the anode conductive connector 14 are approximately along the outer cylinder 30 The axial extension of the electrolysis device 10 is firmly connected with the closed end of the outer cylinder 30 through the installation device 20 .

[0091] For some miniaturized laundry treatment equipment, the space between the inner cylinder and the outer cylinder 30 may be relatively narrow, and in order to generate enough hydroxyl radicals by electrolysis, the electrolysis device 10 needs to have a sufficient working surface area. In the embodiment of the present application, since the electrolysis cathode 11 and the electrolysis anode 12 adopt a layered structure and have a certain ...

no. 2 example

[0099] see Figure 15 to Figure 17 The difference from the first embodiment is that in this embodiment, the cathode conductive connector 13 and the anode conductive connector 14 extend approximately along the radial direction of the outer cylinder 30, that is to say, the cathode conductive connector 13 is approximately perpendicular to the first The support part 110 and the anode conductive connecting body 14 are substantially perpendicular to the second support part 120 , and the electrolysis device 10 is fastened and connected to the outer cylinder 30 through the installation device 20 in the circumferential direction.

[0100] see Figure 15 , the cathode conductive connector 13 and the anode conductive connector 14 are approximately perpendicular to the plane where the electrolytic cathode 11 and the electrolytic anode 12 are located, the electrolytic cathode 11 abuts on the cathode conductive connector 13, and the electrolytic anode 12 abuts on the anode conductive connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com