Washing-free shaping machine and dyeing and shaping process

A setting machine, no water washing technology, applied in the direction of dyeing method, liquid/gas/vapor removal by jet method, equipment configuration for processing textile materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

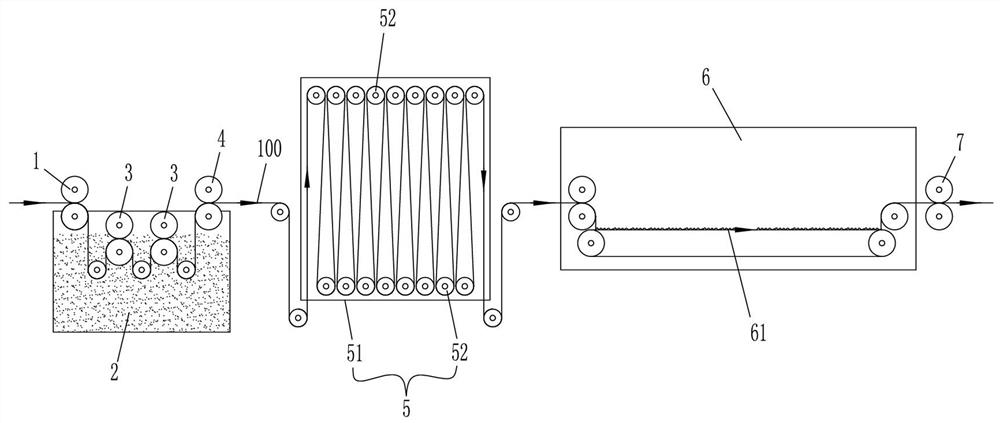

[0023] Below in conjunction with accompanying drawing, the preferred embodiment of water-free setting machine and dyeing setting process of the present invention is described in detail:

[0024] Such as figure 1 As shown, a washing-free setting machine includes a cloth feeding device 1, a dyeing tank 2, a padding car 3, a water rolling device 4, a guide roller type hot air dryer 5, a drying room drying device 6 and a cloth outlet device 7, The padding car 3 is immersed in the dye liquor in the dyeing tank 2, the water rolling device 4 is located above the dyeing tank 2, and the guide roller type hot air dryer 5 includes an oven 51 and two rows of guide rollers 52 up and down in the oven 51. There is a mesh belt transmission device 61 in the room drying device 6. When working, the fabric 100 passes through the cloth feeding device 1, the padding car 3 in the dyeing tank 2, the water rolling device 4, the guide roller hot air dryer 5, and the drying room. The mesh belt transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com