A continuous waste rubber cracking device

A cracking device and waste rubber technology, which is applied in the field of continuous waste rubber cracking devices, can solve the problems of low degree of automation, difficulty in meeting the needs of industrialization, and difficult operation, and achieve the effect of convenient operation, simple structure, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

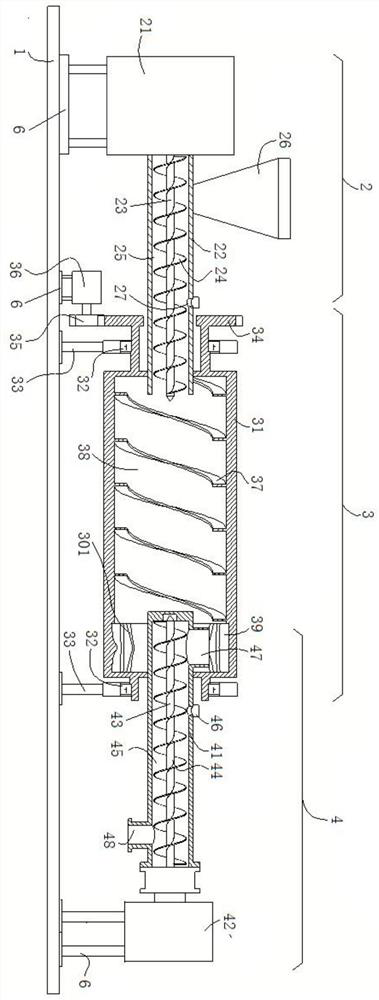

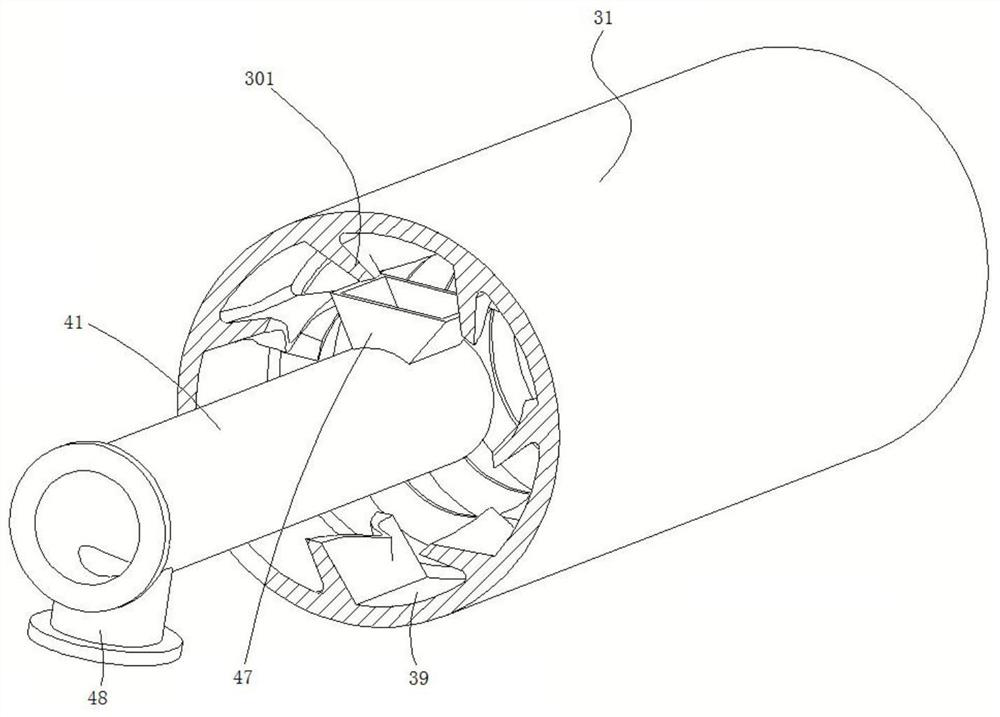

[0015] The main structure of the continuous waste rubber cracking device involved in this embodiment includes a base 1, a mounting frame 6, a feeding motor 21, a feeding barrel 22, a feeding shaft 23, a feeding screw 24, a material conveying cavity 25, a feeding hopper 26, a No. cracking gas outlet 27, cracking furnace 31, bearing 32, bracket 33, driven gear 34, driving gear 35, cracking motor 36, cracking screw 37, cracking chamber 38, cracking furnace trough 39, discharging barrel 41, discharging Motor 42, discharge shaft 43, discharge screw 44, material output cavity 45, No. 2 pyrolysis gas outlet 46 and discharge port 48; the shell of the feeding motor 21 with a rectangular structure and the feeding barrel with an inner hollow circular structure 22 connection, the output shaft of the feeding motor 21 is connected with the feeding shaft 23 of the cylindrical structure provided on the central axis inside the feeding machine barrel 22, and the feeding shaft 23 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com