High-temperature furnace capable of continuously producing artificial graphite

A high-temperature kiln and artificial graphite technology, applied in sustainable manufacturing/processing, climate sustainability, inorganic chemistry, etc., can solve problems such as unsatisfactory furnace core temperature uniformity and large product quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

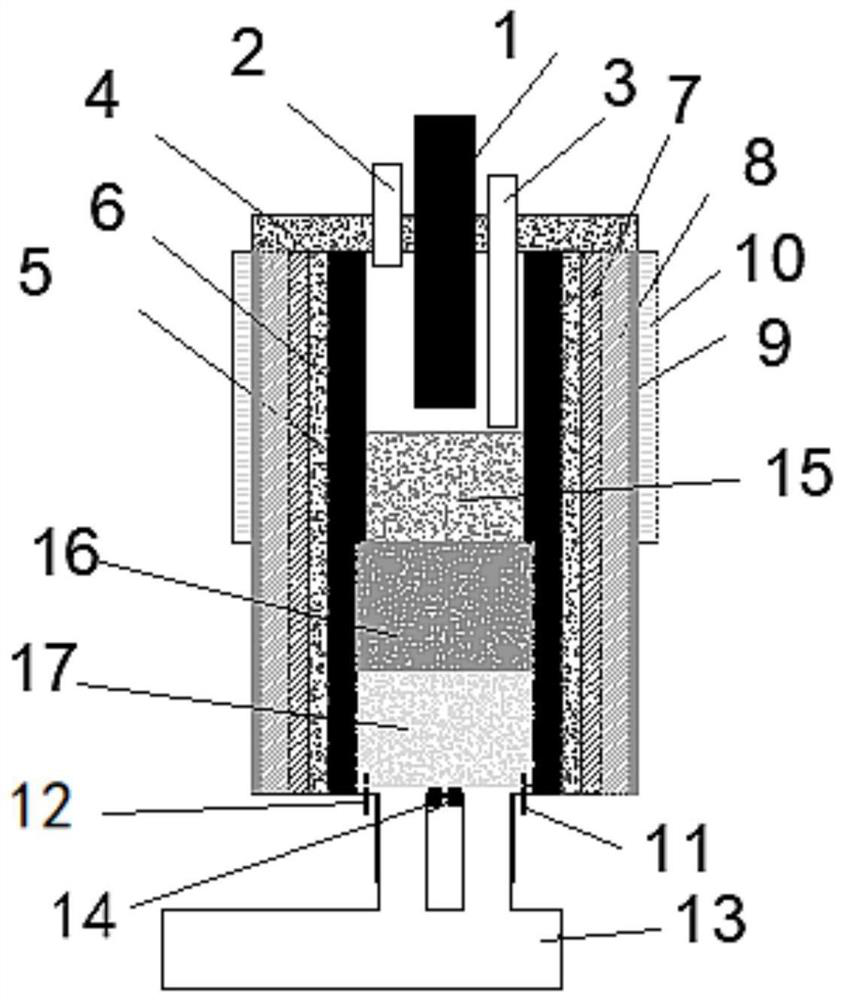

[0020] Such as figure 1 As shown, a high-temperature kiln capable of continuously producing artificial graphite includes a furnace lining, and the working layer of the furnace lining is sequentially provided with a water cooling jacket 10, a low-temperature light-weight insulation layer 8, a medium-temperature layer 7 and a high-temperature layer 6 from the outside to the inside, The upper part of the furnace lining is provided with a furnace cover 4 matched therewith;

[0021] The furnace cover 4 is respectively provided with a smoke exhaust port 2, a graphite electrode positive electrode 1 and a furnace top blanking hole 3;

[0022] The inner wall of the high temperature layer 6 is provided with a graphite electrode negative electrode 5;

[0023] A first distributing valve 11 and a second distributing valve 12 are installed at the bottom of the negative electrode 5 of the graphite electrode, and an inert gas can be introduced into it;

[0024] The bottom of the graphite el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com