A high-efficiency power equipment maintenance device and its application method

A technology for power equipment and maintenance devices, which is applied to mechanical equipment, lifting devices, switchgear, etc., and can solve problems such as increasing the risk of manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

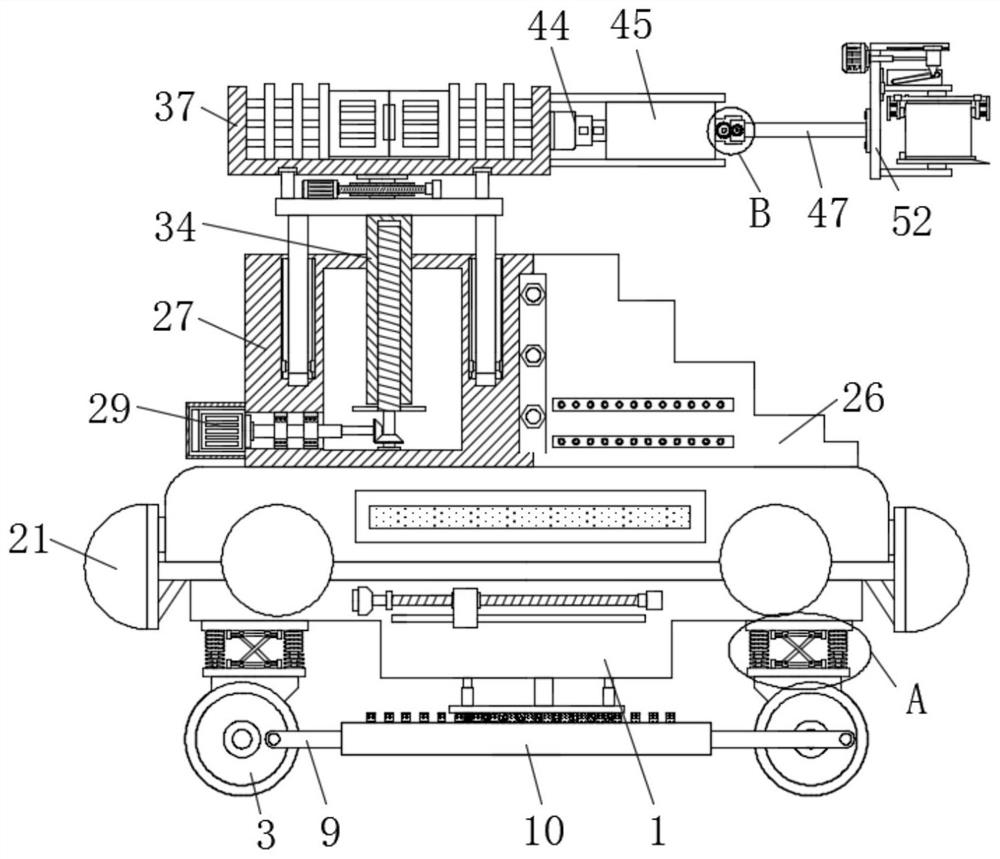

[0048] Embodiment one: if figure 1As shown, a high-efficiency power equipment maintenance device includes a moving base 1, a plurality of hollow elastic balls 21 are fixedly connected to the outer side of the moving base 1, buffer assemblies are arranged on the four corners of the bottom of the moving base 1, and the buffering The bottom of the assembly is fixedly connected with a universal wheel 3, and the rotation on one side of the two universal wheels 3 on the same side deviated from the center of the circle is connected with the same connecting rod 9, and the connecting rod 9 is provided with a brake plate 10 and a moving seat 1 A mounting groove 11 is provided at the bottom of the mounting groove 11, a sliding rod 12 is fixedly connected to the inner wall of the top of the mounting groove 11, and a pushing block 13 is slidably connected to the sliding rod 12, and one side of the moving seat 1 is fixedly connected with a horizontal moving position for adjusting the pushing...

Embodiment 2

[0065] Embodiment two: if Figure 7 As shown, two buffer springs 24 symmetrically arranged are fixedly connected to one side of the inner wall of the hollow elastic ball 21, and one side of the two buffer springs 24 is fixedly connected to the same buffer plate 22, and one side of the buffer plate 22 There are three fixed plates 23 fixedly connected, and the other ends of the three fixed plates 23 are fixedly connected with the side wall of the inner cavity of the hollow elastic ball 21, and one side of the buffer plate 22 is fixedly connected with two symmetrically arranged buffer sheets 25, and The two buffer springs 24 are located between the two buffer pieces 25 , and the other end of the buffer piece 25 is fixedly connected to one inner wall of the hollow elastic ball 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com