Animal and vegetable oil storage tank with spoilage prevention function

An animal and vegetable oil and anti-deterioration technology, applied in the field of storage tanks, can solve the problems of poor mixing effect of storage tanks, long time, affecting users' experience of using storage tanks, etc., and achieve the effect of rich functions, convenient use and improved user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

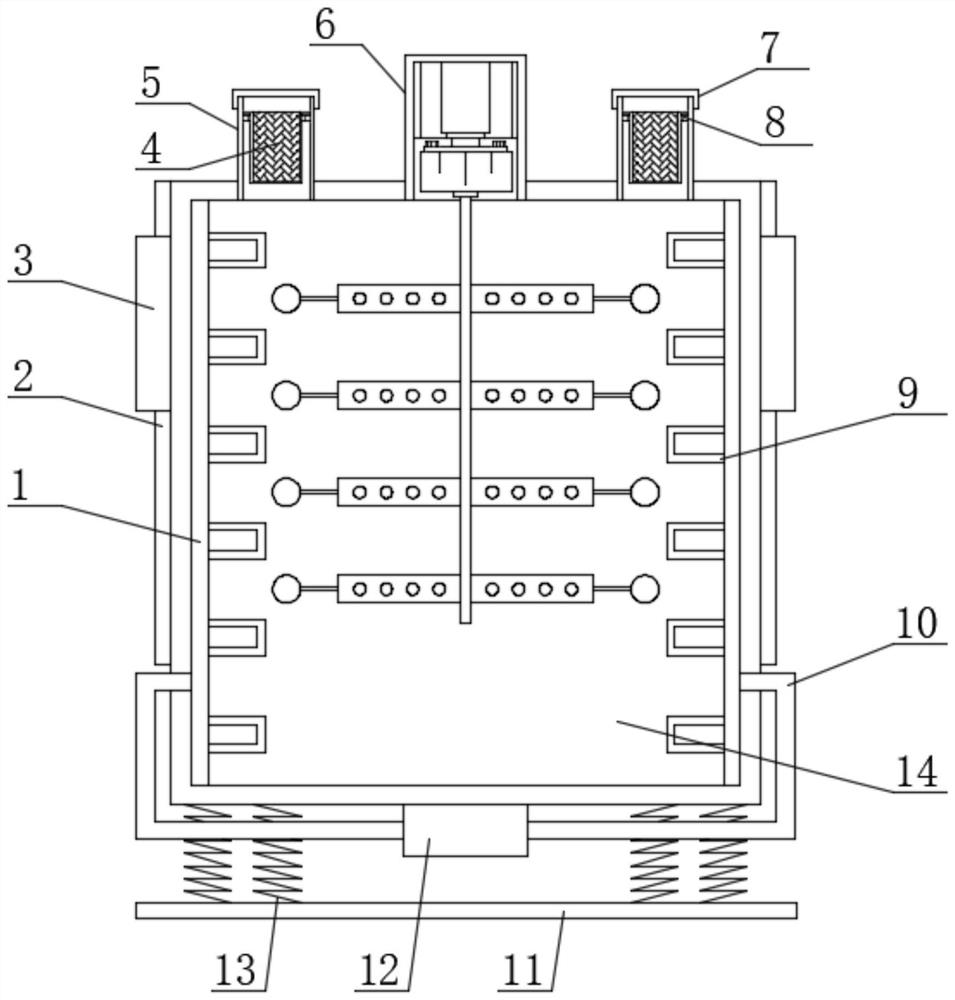

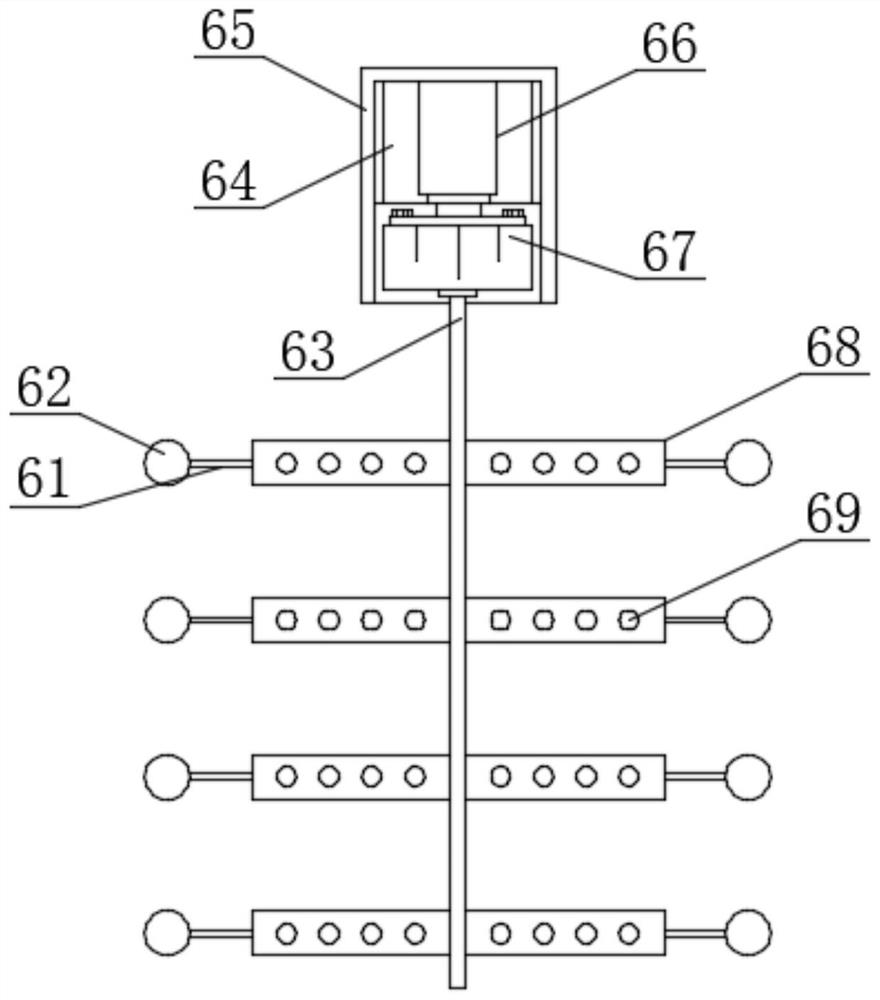

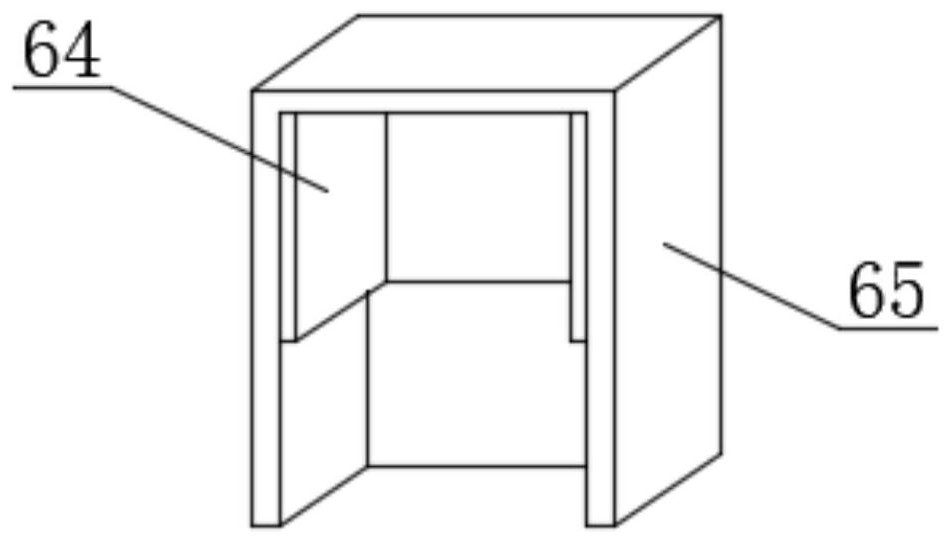

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a kind of animal and vegetable oil storage tank with anti-deterioration function, comprising a tank body 14, the use of the tank body 14 is the prior art, the bottom end of the tank body 14 is welded with a discharge pipe, the tank body The two ends of the upper surface of 14 are welded with feeding pipe 5, the inner wall of the tank body 14 is provided with a cooling plate 1, the lower surface of the tank body 14 is provided with a refrigerator 12, and the output end of the refrigerator 12 is provided with a Corresponding to the connecting pipe 10, the side of the cooling plate 1 is provided with a cooling pipe 9, the bottom of the cooling plate 1 is provided with a support base plate 11, and the two ends of the upper surface of the support base plate 11 are provided with limit springs 13 corresponding to the tank body 14, The top of the tank body 14 is provided with a vibrating motor 3, and ...

Embodiment 2

[0027] On the basis of embodiment 1, in order to make the function of storage tank more abundant, in the present embodiment, preferably, the inside of feed pipe 5 is provided with filter funnel 4, and the material of filter funnel 4 is stainless steel, and the material of feed pipe 5 The inner wall is provided with a limiter 8 corresponding to the filter funnel 4, and the oil is filtered through the filter funnel 4 during use, and when an antioxidant needs to be added, the filter funnel 4 can be taken out directly;

[0028] In order to make the limiting effect of the limiting member 8 better, in this embodiment, preferably, the feeding pipe 5 and the limiting member 8 are fixedly connected by welding, and the top of the feeding pipe 5 is provided with a protective top cover 7 to protect the The material of top cover 7 is stainless steel.

[0029] Working principle and application process of the present invention: when in use, oil is injected into the tank body 14 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com