Non-notched cap and body stainless steel capsule mold

A stainless steel and mold technology, applied in the directions of capsule delivery, pharmaceutical formulation, coating, etc., can solve the problems of increasing the production steps of hollow capsules, increasing the production cost, scrapping burr waste, etc., to simplify the subsequent processing steps, reduce the waste of raw materials, and the effect of excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

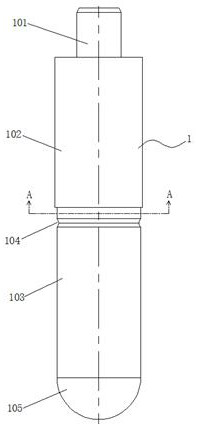

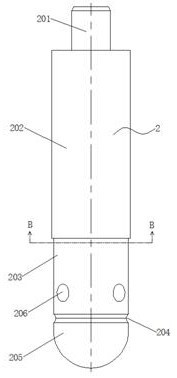

[0029] This embodiment discloses a cap and body stainless steel capsule mold without notch, which includes a capsule body mold 1 and a capsule cap mold 2 .

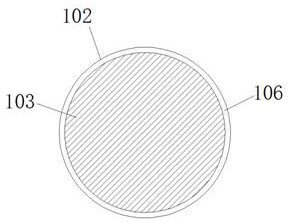

[0030] Reference attached figure 1 And attached figure 2 , its capsule mold 1 includes a first connecting portion 101, a first upper cylinder 102 and a first lower cylinder 103, wherein the first connecting portion 101, the first upper cylinder 102 and the first lower cylinder 103 are from top to bottom The lower and lower are connected in turn, and the axes of the three are coincident and set. Wherein, the diameter of the first upper cylinder 102 is greater than the diameter of the first lower cylinder 103. When specifically set, the diameter of the first upper cylinder 102 in this embodiment is 7.36 mm, and the diameter of the first lower cylinder 103 is 7.19 mm. mm. Because the diameter of the first upper cylinder 102 is greater than the diameter of the first lower cylinder 103, it forms a first annular retaining s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com