Snake-shaped robot snake body joint with three-way steering engine orthogonal connection structure

A snake-shaped robot and orthogonal connection technology, applied in the field of bionic robots, can solve problems such as insufficient spatial freedom, unreasonable structural design, and inflexible movement, achieving flexible movement, solving inflexible movement, and high spatial freedom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

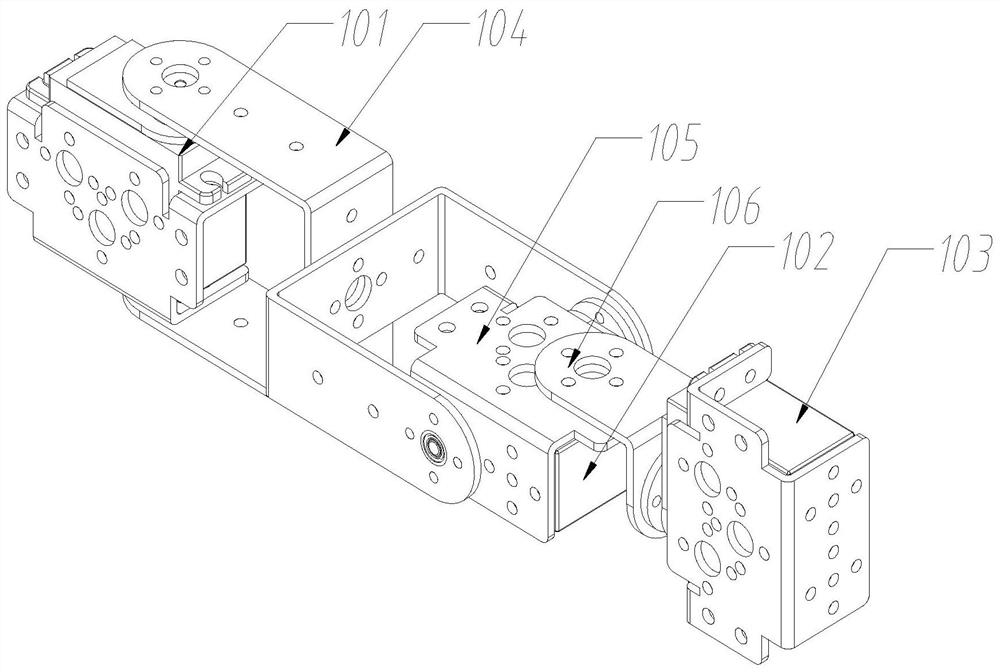

[0015] Attached below Figures 1 to 4 , to further illustrate a specific embodiment of a snake body joint of a snake robot with a three-way steering gear orthogonal connection structure of the present invention.

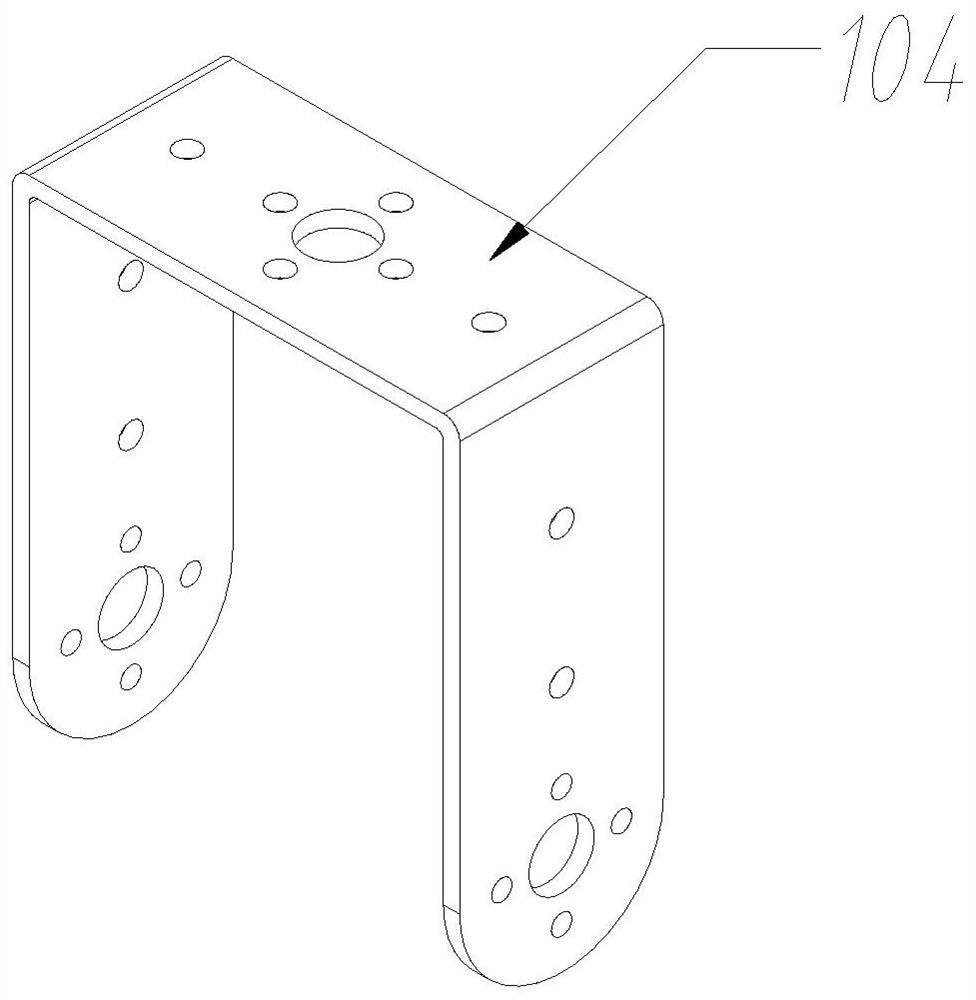

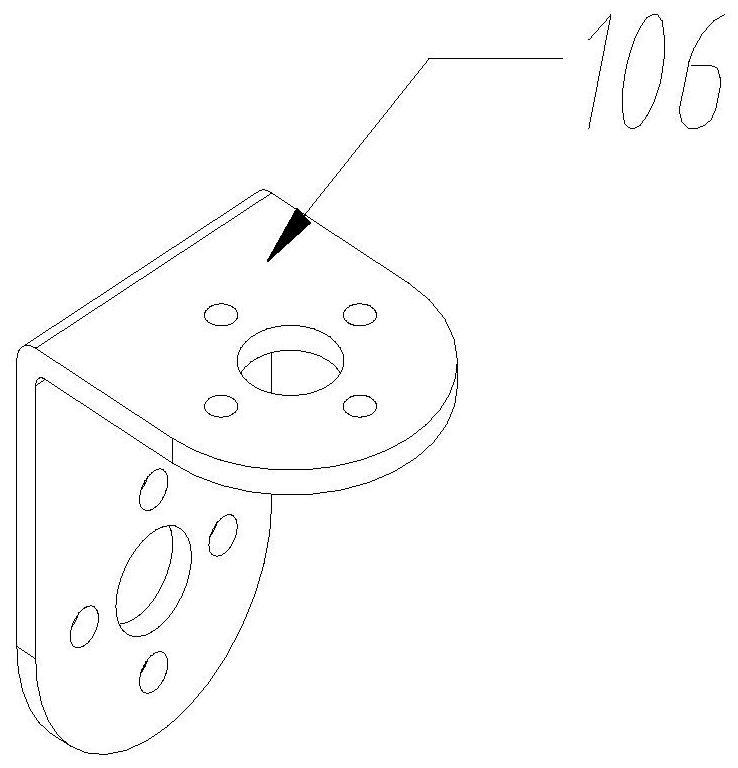

[0016] like figure 1 As shown, it is a snake body joint of a snake-shaped robot with a three-way steering gear orthogonal connection structure. The snake body joint is provided with an X-direction steering gear (101) and a Y-direction steering gear (103) whose output shaft is in the horizontal direction. , the output shaft is the Z steering gear (102) in the vertical direction, the output direction of the X steering gear (101) and the Y steering gear (103) are vertically orthogonal in the plane space, and the Z steering gear ( The output direction of 102) is vertically orthogonal to the output direction of the X-direction steering gear (101) Y-direction steering gear (103) in space, and the X-direction steering gear (101) Y-direction steering gear (103) Z-direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com