Method for preparing basic nickel silicate catalyst from silicon-containing industrial solid waste

A solid waste and nickel silicate technology, which is applied in the field of solid waste resource utilization, can solve the problems of complex process, high cost and harsh preparation conditions, and achieve the effects of high purity, simple operation and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

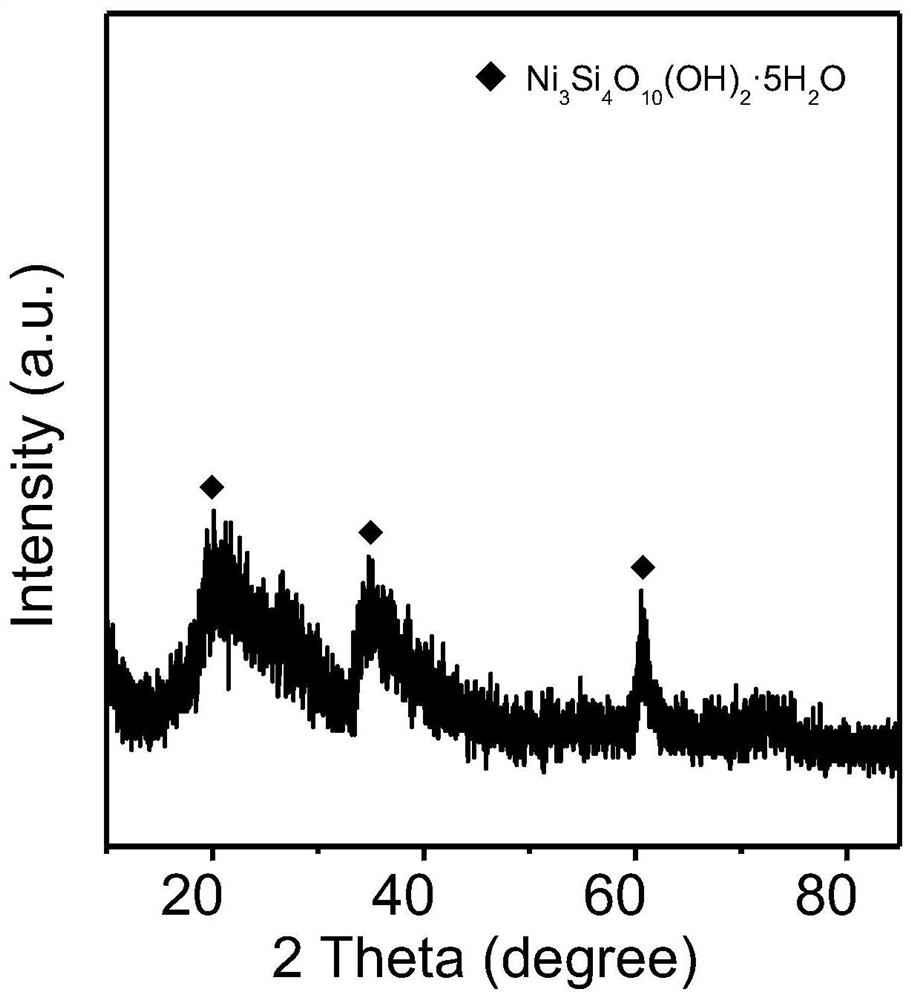

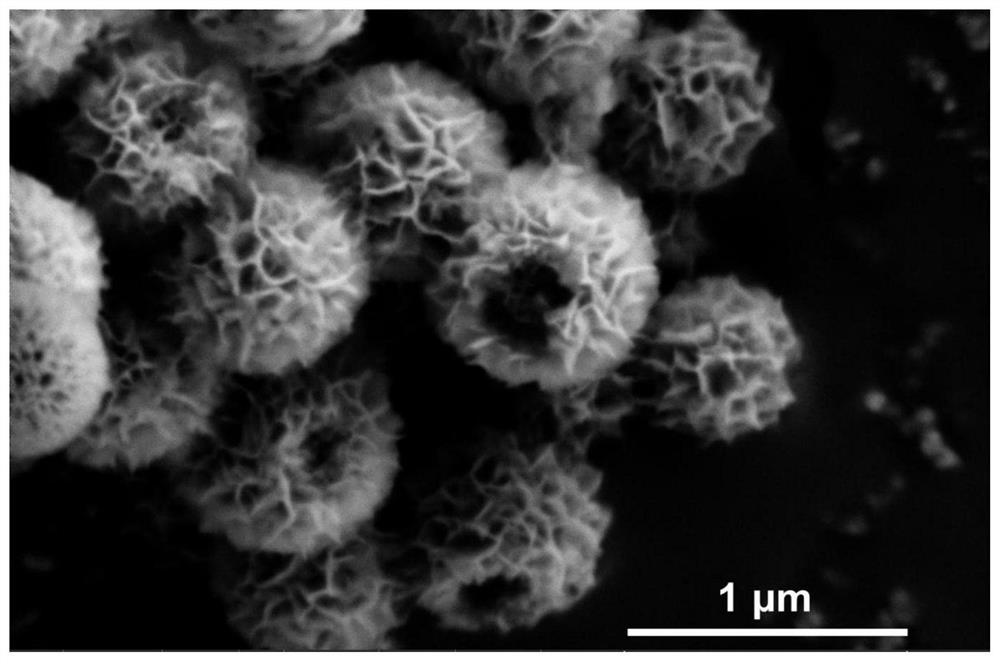

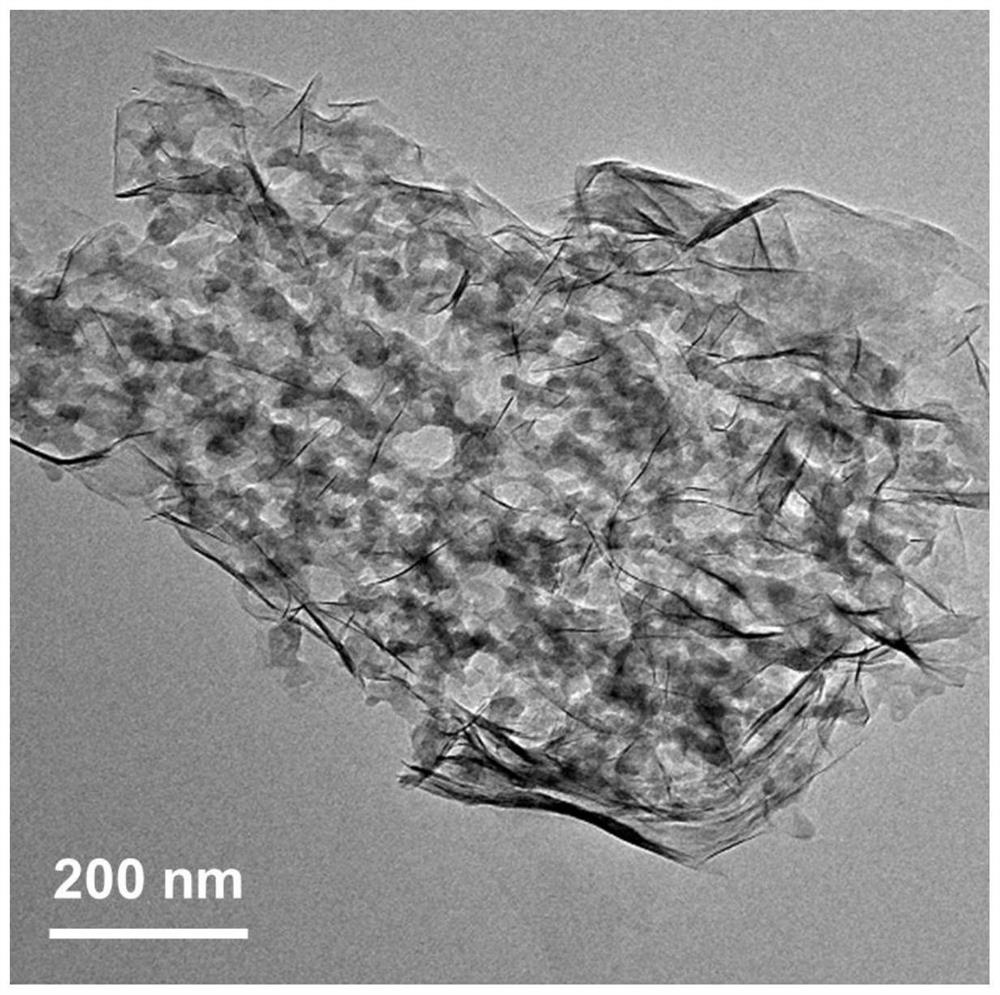

[0023] After pulverizing the filter residue of fluosilicic acid waste water, put it in the muffle furnace at 600 o Roasting at C for 6 h activation, the activated fluosilicic acid wastewater filter residue and 16 mol / L NH 4 F solution is the reaction raw material, at 100 o C for 2 h and filtered while hot. NH produced during the reaction 3 Collected with deionized water to obtain NH 3 ·H 2 O. Add the filtrate to the above NH 3 ·H 2 O, 50 o After heating and stirring for 1 h at C, the stirring was stopped, and the resulting slurry was heated at 50 o C sinks for 3 h, then filters and washes for 80 o C under vacuum drying for 12 h, and the ammonium fluoride in the filtrate was recycled as a reactant for the next reaction. Then 1 g of the treated solid powder was dispersed in an aqueous solution containing 30 g of nickel nitrate, ultrasonically treated for 10 min, and then moved to a hydrothermal kettle at 240 o Under the environment of C, the water is heated for 12 h. ...

Embodiment 2

[0025] The oil shale ash and iron tailings are crushed and placed in the muffle furnace at 900 o Activated by roasting at C for 2 h, using activated oil shale ash and iron tailings and 22 mol / L NH 4 F solution is the reaction raw material, at 120 o C for 8 h and filtered while hot. NH produced during the reaction 3 Collected with deionized water to obtain NH 3 ·H 2 O. Add the filtrate to the above NH 3 ·H 2 O, 80 o After heating and stirring for 1 h at C, the stirring was stopped, and the resulting slurry was heated at 80 o C sinks for 3 h, then filters and washes for 90 o C under vacuum for 36 h, the ammonium fluoride in the filtrate was recycled as a reactant for the next reaction. Then 1 g of the treated oil shale ash and iron tailings were dispersed in an aqueous solution containing 25 g of nickel nitrate, ultrasonically treated for 10 min, and then transferred to a hydrothermal kettle at 220 o Under the environment of C, the water is heated for 24 hours. Filte...

Embodiment 3

[0027] After crushing the waste diatomaceous earth, put it in the muffle furnace at 800 o Activated by roasting at C for 6 h, using activated waste diatomaceous earth and 10 mol / L NH 4 F solution is the reaction raw material, at 60 o C for 6 h and filtered while hot. NH produced during the reaction 3 Collected with deionized water to obtain NH 3 ·H 2 O. Add the filtrate to the above NH 3 ·H 2 O, 50 o After heating and stirring for 1 h at C, the stirring was stopped, and the resulting slurry was heated at 50 o C sinks for 3 h, then filters and washes for 90 oC under vacuum for 26 h, the ammonium fluoride in the filtrate was recycled as a reactant for the next reaction. Then 1 g of waste diatomaceous earth after treatment was dispersed in an aqueous solution containing 25 g of nickel nitrate, ultrasonically treated for 10 min, and then moved to a hydrothermal kettle at 150 o Under the environment of C, the water is heated for 48 h. Filtered, washed several times with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com