Stripping composition, stripping reagent, application thereof, method for preparing same, and method for stripping reconstituted tobacco leaf

A technology for reconstituted tobacco leaves and a composition, which is applied in the field of preparation of reconstituted tobacco leaves, can solve problems such as the inability to effectively increase production speed, affect product quality, reduce product yield and the like, achieve excellent industrial application prospects, improve integrity and quality, and achieve good results. The effect of peeling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

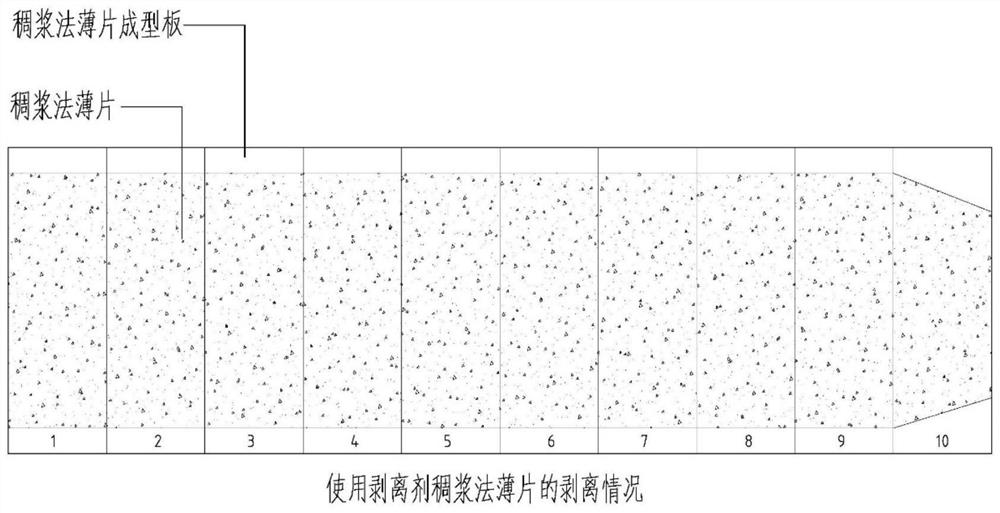

[0051] Further, an embodiment of the present invention also provides a method for preparing a peeling agent, comprising: preparing a peeling composition as the peeling agent;

[0052] Preferably, linolenic acid and linseed oil are mixed to form the first component;

[0053] palmitic acid, behenic acid, stearic acid, lauric acid, gelatin, starch, sodium alginate, sodium lauryl phosphate and vitamin E are mixed to form a second component; then the first component and the The second component is mixed with a solvent to form the stripping reagent; the mixing conditions are: rotation speed: 2000-9000 rpm, time 1-10 minutes. Using the above method to prepare the stripping reagent can ensure the stripping effect of the stripping reagent. And when a flavoring material is included, the flavoring material is added in the second component.

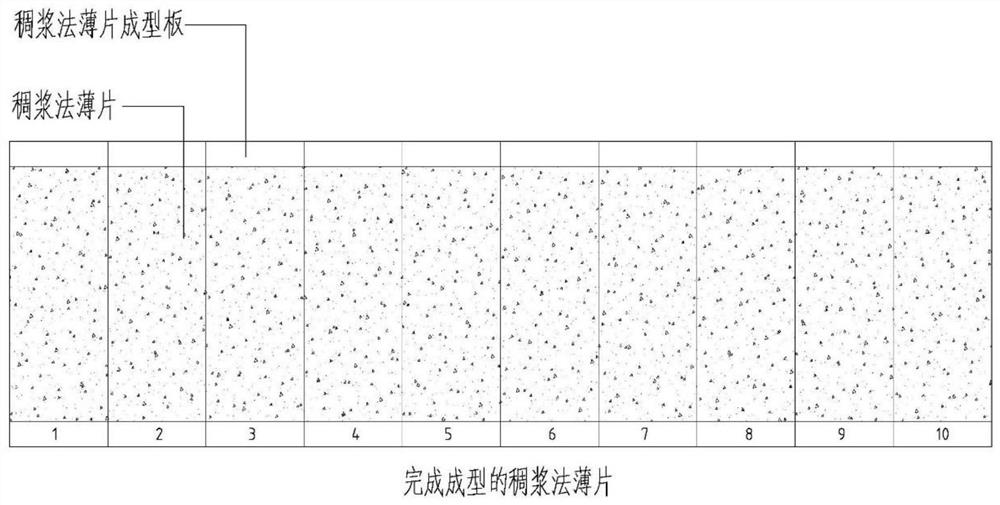

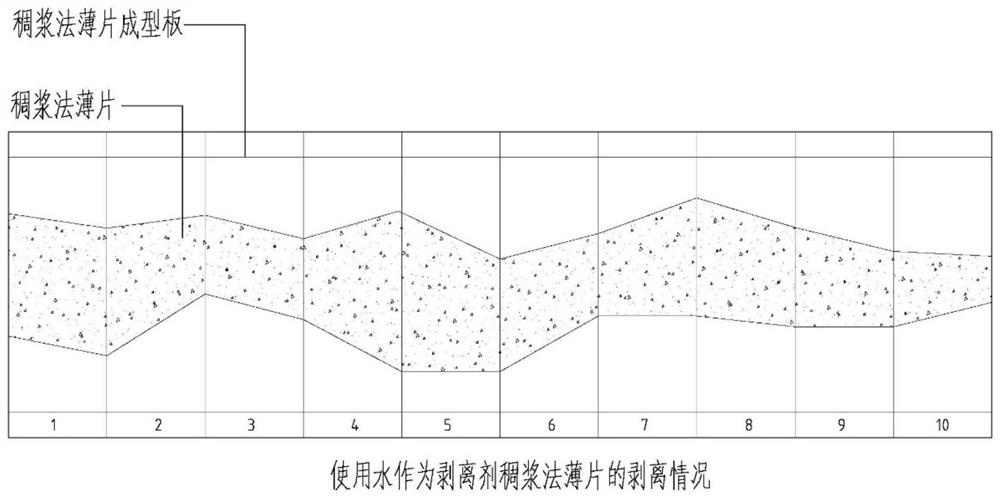

[0054] Further, an embodiment of the present invention also provides a method for stripping and reconstituting tobacco leaves, comprising:

[005...

Embodiment 1

[0059] This embodiment provides a peeling composition, wherein the mass of linolenic acid, the linseed oil, the palmitic acid, the behenic acid, the stearic acid and the lauric acid all account for the mass of the peeling composition 10% of the mass; the mass of the gelatin, the starch, the sodium alginate, the sodium lauryl phosphate and the vitamin E all account for 7% of the mass of the peeling composition; the flavoring material The mass of the peeling composition accounts for 5% of the mass of the peeling composition.

[0060] This embodiment also provides a peeling agent, which is an emulsion, which includes the peeling composition and water, and each gram of the peeling agent contains 0.4 grams of the peeling composition.

[0061] The present embodiment also provides a method for preparing the above-mentioned peeling agent, comprising: mixing linolenic acid and linseed oil to form a first mixture, mixing remaining raw materials to form a second mixture, and then mixing ...

Embodiment 2

[0066] This embodiment provides a peeling composition, wherein the mass of linolenic acid, the linseed oil, the palmitic acid, the behenic acid, the stearic acid and the lauric acid account for the proportion of the peeling composition in order 1%, 20%, 5%, 15%, 10%, 20% of the mass; the mass of the gelatin, the starch, the sodium alginate, the sodium lauryl phosphate and the vitamin E are in order It accounts for 5%, 1%, 5%, 10%, and 4% of the mass of the peeling composition; the mass of the flavoring material accounts for 4% of the mass of the peeling composition.

[0067] This embodiment also provides a peeling agent, which is an emulsion, which includes the peeling composition and water, and each gram of the peeling agent contains 0.6 grams of the peeling composition.

[0068] The present embodiment also provides a method for preparing the above-mentioned peeling agent, comprising: mixing linolenic acid and linseed oil to form a first mixture, mixing remaining raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com