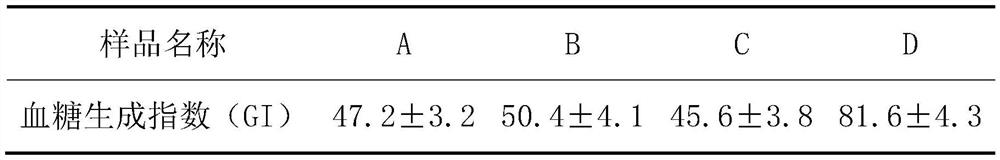

Low-GI eucommia ulmoides male flower coarse cereal fine dried noodles and preparation method thereof

A technology of eucommia male and male flower, which is applied in the field of food processing and can solve the problems of people with diabetes and people with abnormal blood sugar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

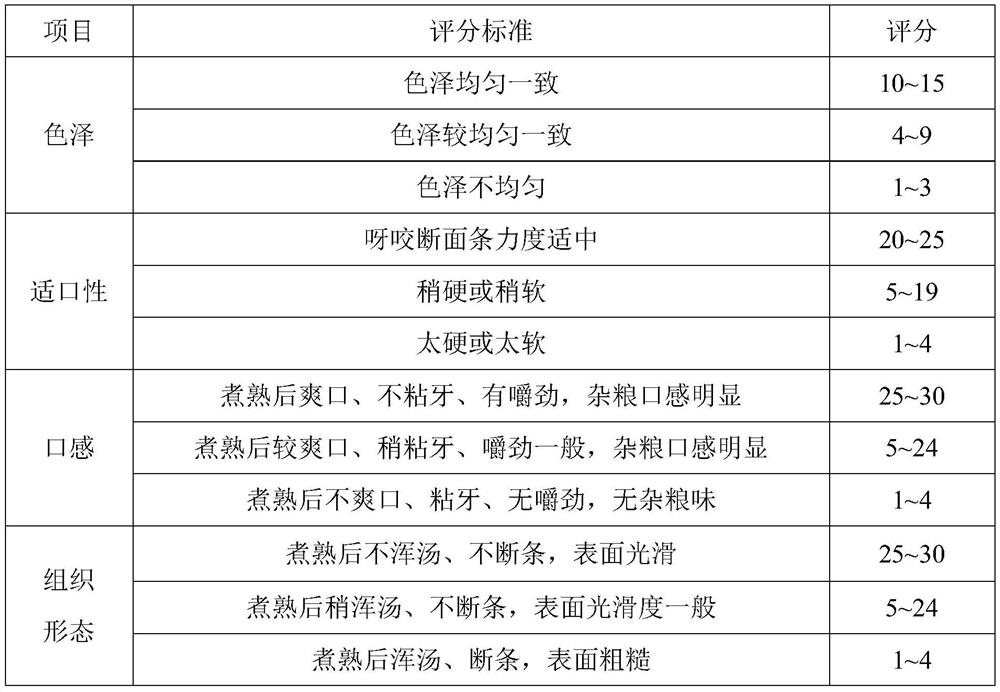

Examples

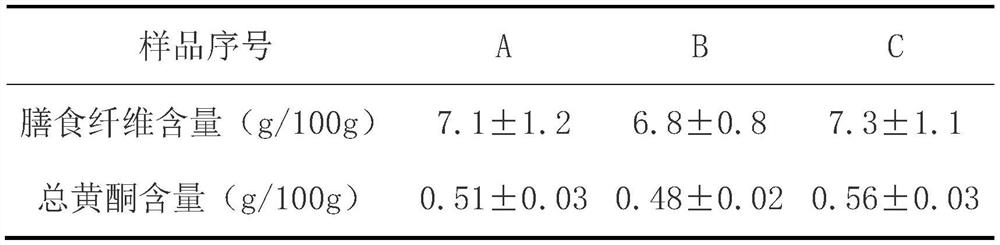

Embodiment 1

[0033] The specific preparation process of the low GI fine grain vermicelli of the present embodiment is as follows:

[0034] S1. Vacuum kneading

[0035] First take each raw material in proportion, in parts by weight, 18 parts of flour, 38 parts of tartary buckwheat flour, 28 parts of highland barley flour, 18 parts of quinoa flour, 8 parts of eucommia male pollen, 8 parts of black gold rice flour, 4 parts of quality improver ( 3 parts of gluten powder, 0.5 part of edible salt, 0.2 part of food grade sodium carbonate, 0.2 part of xanthan gum, 0.1 part of linseed gum in the quality improver).

[0036] The flour wet basis gluten quality ≥ 30.0%, dry basis protein ≥ 12.2%, dry basis ash content ≤ 0.70%.

[0037] Mix uniformly in a mixer in the order of mass parts from low to high to obtain a mixed powder; put the mixed powder into a vacuum dough mixer, and slowly add 32 parts of water to prepare a dough. The temperature of the vacuum kneading dough is 25°C, the vacuum degree i...

Embodiment 2

[0045] S1. Vacuum kneading

[0046] First weigh each raw material in proportion, in parts by weight, 20 parts of flour, 35 parts of tartary buckwheat powder, 28 parts of highland barley powder, 15 parts of quinoa powder, 5 parts of eucommia pollen, 8 parts of blood oat powder, and 5 parts of quality improver (4 parts of gluten powder, 0.5 part of edible salt, 0.2 part of food grade sodium carbonate, 0.2 part of xanthan gum, 0.1 part of linseed gum in the quality improver).

[0047] The flour wet basis gluten quality ≥ 30.0%, dry basis protein ≥ 12.2%, dry basis ash content ≤ 0.70%.

[0048] Mix uniformly in the mixer in the order of mass parts from low to high to obtain mixed powder; put the mixed powder into a vacuum dough mixer, and slowly add 30 parts of water to prepare dough. The temperature of the vacuum kneading dough is 30°C, the vacuum degree is 0.06MPa, the rotation speed is 120r / min, and the vacuum kneading kneading time is 18min.

[0049] S2, calendering

[0050...

Embodiment 3

[0056] S1. Vacuum kneading

[0057] First take each raw material in proportion, in parts by weight, 20 parts of flour, 40 parts of tartary buckwheat powder, 30 parts of highland barley powder, 20 parts of quinoa powder, 10 parts of eucommia male pollen, 10 parts of black gold rice flour, 6 parts of quality improver ( 5 parts of gluten powder, 0.5 part of edible salt, 0.2 part of food-grade sodium carbonate, 0.2 part of xanthan gum, and 0.1 part of linseed gum in the quality improver).

[0058] The flour wet basis gluten quality ≥ 30.0%, dry basis protein ≥ 12.2%, dry basis ash content ≤ 0.70%.

[0059] Mix uniformly in the mixer in the order of mass parts from low to high to obtain mixed powder; put the mixed powder into a vacuum dough mixer, slowly add 35 parts of water to prepare dough. The temperature of vacuum kneading is 30°C, the degree of vacuum is 0.08MPa, the rotation speed is 110r / min, and the vacuum kneading is 20min.

[0060] S2, calendering

[0061] After putti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com