Fertilization equipment used for agricultural machinery and fertilization method used for agricultural machinery

A technology of agricultural machinery and equipment, which is applied in the field of fertilization equipment and fertilization for agricultural machinery, and can solve the problems of uncontrollable fertilization amount, large loss of fertilizer nutrients, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

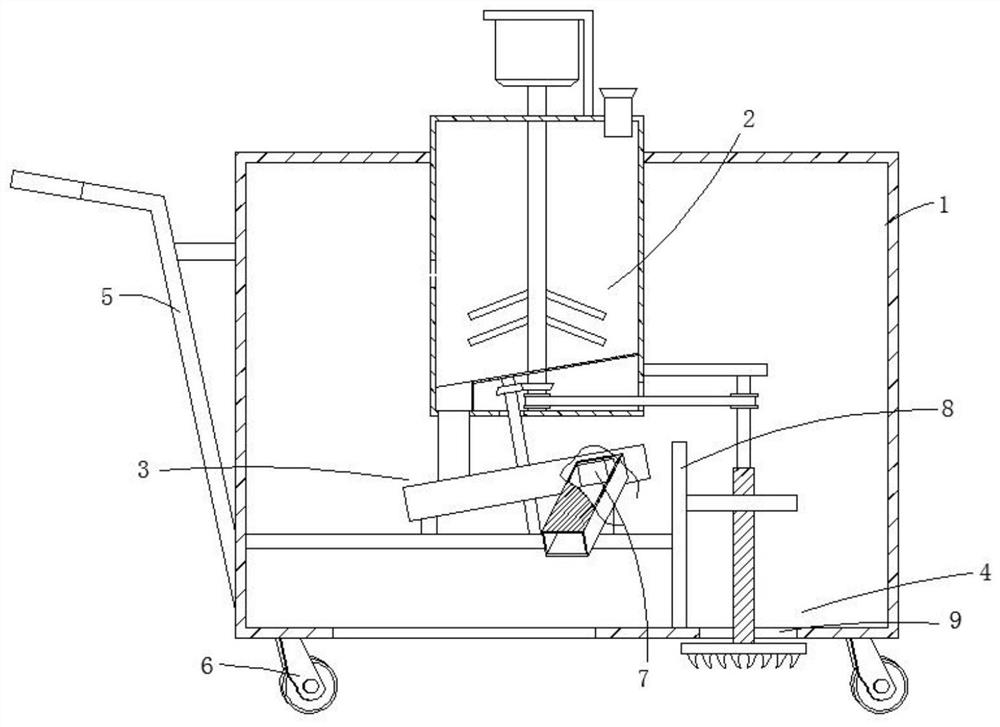

[0042] see Figure 1-9 , the present invention provides a technical solution: a fertilization equipment for agricultural machinery, comprising a device housing 1, a stirring mechanism 2, a uniform feeding mechanism 3 and a loosening mechanism 4, the left side of the device housing 1 is provided with a push rod 5, the device The bottom of shell 1 is equipped with moving wheel 6, and even feeding mechanism 3 is installed below stirring mechanism 2, and soil loosening mechanism 4 is installed in the right side of uniform feeding mechanism 3.

[0043] The stirring mechanism 2 comprises a stirring chamber 201, a servo motor 202, a stirring shaft 203, a stirring rod 204, a transmission chamber 205 and a feeding cylinder 206, the stirring chamber 201 is fixedly connected to the top of the device housing 1, and the transmission chamber 205 is arranged on the top of the stirring chamber 201. bottom, and the bottom of the mixing chamber 201 near the left end of the transmission chamber ...

Embodiment 2

[0048] On the basis of embodiment 1,

[0049] The bottom of the device shell 1 is also provided with a bulk material mechanism, which includes a discharge hopper 21, an arc-shaped sieve plate 22 and an elastic connecting ring 23. The discharge hopper 21 is inserted in the middle of the bottom of the device shell 1 and is located in the lower barrel. Below 308 , the arc-shaped sieve plate 22 is movably connected to the upper end of the discharge hopper 21 , and the elastic connecting ring 23 is installed on the outer wall of the discharge hopper 21 and located on the upper and lower sides of the arc-shaped sieve plate 22 .

[0050] Wherein, above the arc-shaped sieve plate 22, a vibrating mechanism is provided, and the vibrating mechanism includes a third main bevel gear 24, a third secondary bevel gear 25, a third rotating rod 26, a movable sleeve 27, a mounting rod 28 and an arc block. 29. The support plate 301 is provided with a square hole 30, and the third rotating rod 26 ...

Embodiment 3

[0053] On the basis of embodiment 2,

[0054] The left side of device housing 1 is also provided with earth-covering mechanism, and earth-covering mechanism comprises the second rotating rod 31, the second transmission wheel 32, the second conveyor belt 33, the gear plate 34, the first transmission disk 35, the second transmission disk 36, the first Soil-covering rod 37 and second soil-covering rod 38 (a section of the first soil-covering rod 37 and the second soil-covering rod 38 near the bottom surface is arc-shaped to improve the effect of gathering soil), the second rotating rod 31 is connected to the support plate 301 in rotation, And the top of the second rotating rod 31 extends to the top of the device housing 1, the second drive wheel 32 is provided with two groups, one group is installed on the top of the second rotating rod 31, and the other group is installed on the upper end of the stirring shaft 203, The second conveyor belt 33 is sleeved between two groups of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com