A four-layer multi-block tunnel spraying operation planning method for automatic wet spraying machine

A wet spraying and spraying technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems such as the inability to meet the operation requirements of automatic wet spraying machines, and achieve the effect of improving quality and homogenizing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

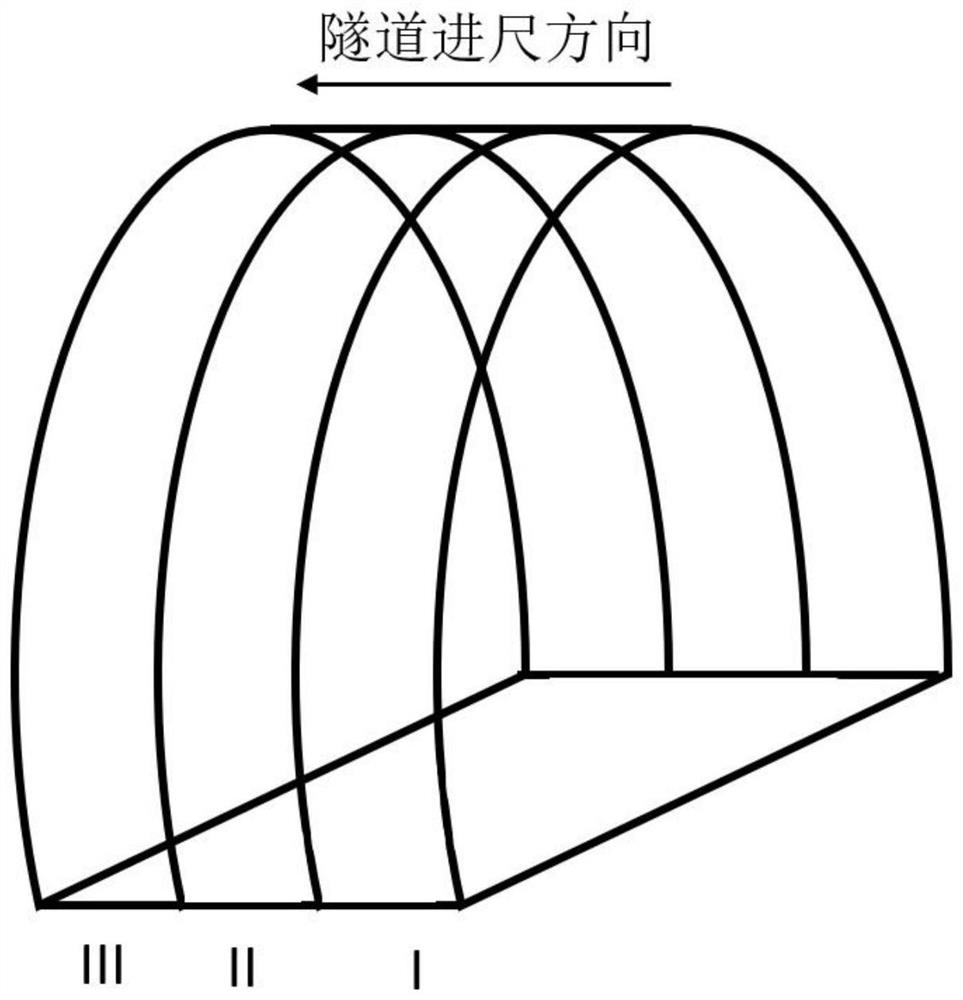

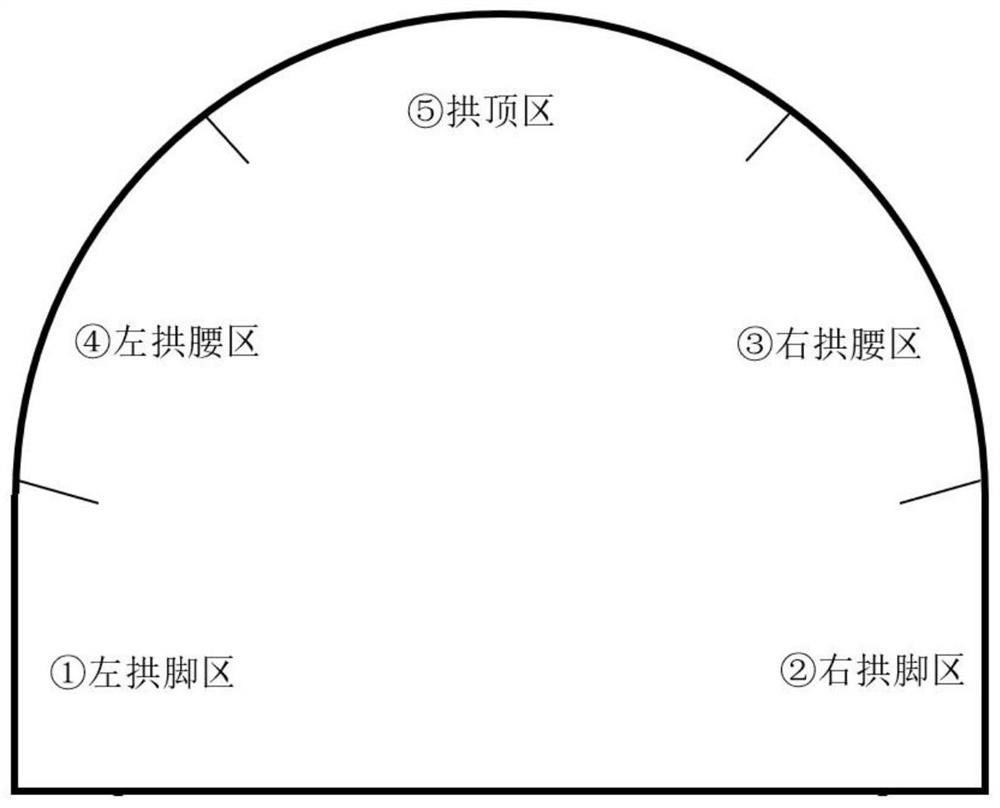

[0039] A four-layer multi-block tunnel shotcrete operation planning method for an automatic wet spraying machine, the planning method comprising the following steps:

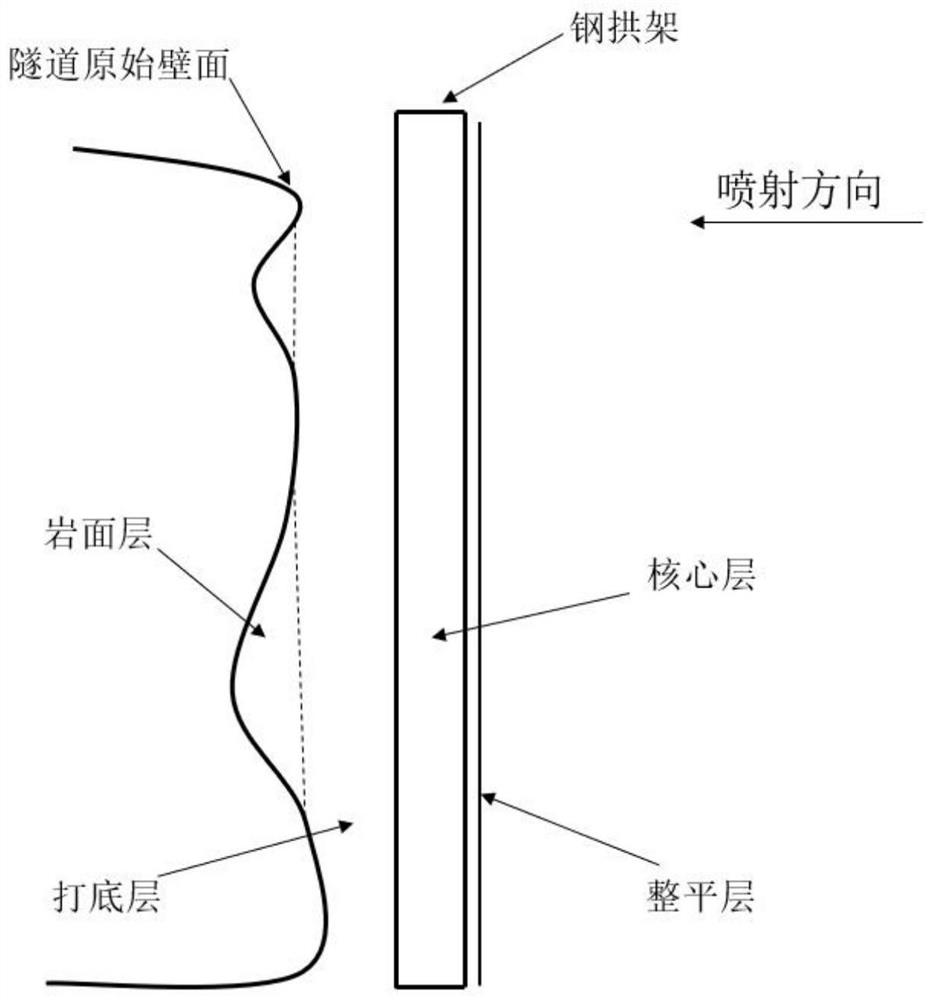

[0040] Step 1: Shotcrete of the rock surface layer is to pretreat the original rock surface formed by blasting;

[0041] Step 2: On the basis of step 1, the bottom layer shotcrete is performed, starting from the rock surface until the area behind the covered steel arch is shot;

[0042] Step 3: On the basis of step 2, the core layer is sprayed, and the middle of the adjacent steel arch is sprayed on the basis of the bottom layer shotcrete;

[0043] Step 4: On the basis of step 3, spray the leveling layer, and continue to spray concrete with a thickness of 3 cm on the basis of the completion of the core layer spraying.

[0044] Further, the step 1 is specifically to fill up the pit on the original rock surface, and the method used in the shotcrete operation of the rock surface layer is to spray at a fixed attitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com