Modification method for reducing water absorption rate of recycled coarse aggregate

A technology for regenerating coarse aggregate and water absorption rate, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of resource waste, high equipment cost, high power consumption, etc. The effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

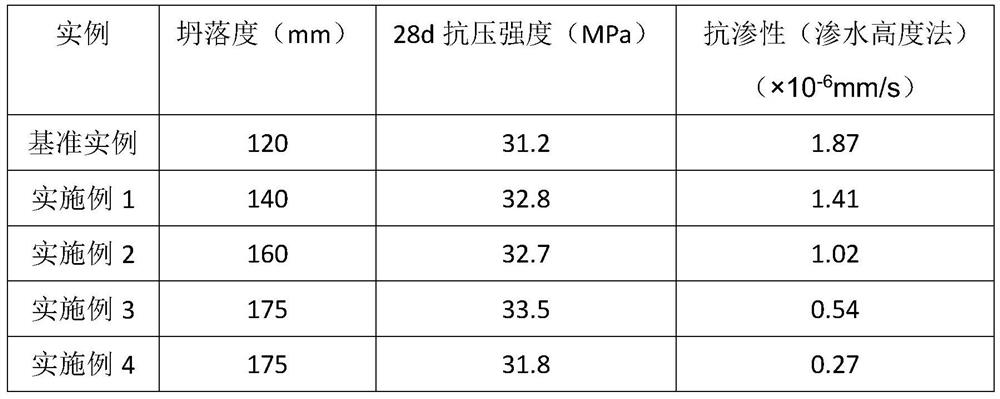

Examples

Embodiment 1

[0024] A modification method for reducing the water absorption of recycled coarse aggregate, the method comprising the following steps:

[0025] 1) Soak and stir the recycled coarse aggregate in tap water, remove it, rinse it twice with tap water, and let it dry naturally until the surface is dry;

[0026] 2) place the recycled coarse aggregate dried in step 1) on the grid-shaped crawler belt, and transport to the nano paraffin emulsion atomization area;

[0027] 3) The nano paraffin emulsion is sprayed through the atomization equipment to form a nano paraffin emulsion spray, which is sprayed out through the nozzles above and below the track in the atomization area, thereby adsorbing on the surface of the aggregate, and the adsorption amount is 0.2% of the mass of the recycled aggregate.

[0028] 4) Dry the recycled coarse aggregate naturally to obtain the modified recycled aggregate.

[0029] Among them, the grid track is a grid made of steel wire, and the grid aperture is 4...

Embodiment 2

[0032] 1) Soak and stir the recycled coarse aggregate in tap water, remove it, rinse it twice with tap water, and let it dry naturally until the surface is dry;

[0033] 2) place the recycled coarse aggregate dried in step 1) on the grid-shaped crawler belt, and transport to the nano paraffin emulsion atomization area;

[0034] 3) The nano-paraffin emulsion is sprayed through the atomization equipment to form a nano-paraffin emulsion spray, which is sprayed out through the nozzles above and below the track in the atomization area, thereby adsorbing on the surface of the aggregate, and the adsorption amount is 0.6% of the mass of the recycled aggregate.

[0035] 4) Dry the recycled coarse aggregate naturally to obtain the modified recycled aggregate.

[0036] Among them, the grid track is a grid made of stainless steel wire, and the grid aperture is 4mm. The size of recycled coarse aggregate is 5mm ~ 40mm, and it is spread on the crawler as a layer, and there is a gap between ...

Embodiment 3

[0039] 1) Soak and stir the recycled coarse aggregate in tap water, remove it, rinse it twice with tap water, and let it dry naturally until the surface is dry;

[0040] 2) place the recycled coarse aggregate dried in step 1) on the grid-shaped crawler belt, and transport to the nano paraffin emulsion atomization area;

[0041] 3) The nano-paraffin emulsion is sprayed through the atomization equipment to form a nano-paraffin emulsion spray, which is sprayed out through the nozzles above and below the track in the atomization area, thereby adsorbing on the surface of the aggregate, and the adsorption amount is 1% of the mass of the recycled aggregate.

[0042] 4) Dry the recycled coarse aggregate naturally to obtain the modified recycled aggregate.

[0043]Among them, the grid track is a grid made of stainless steel wire, and the grid aperture is 4.75mm. The size of recycled coarse aggregate is 5mm ~ 40mm, and it is spread on the crawler as a layer, and there is a gap between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com