Rotor wing model with cutting wing type of picking unmanned aerial vehicle

A technology with cutting and unmanned aerial vehicles, which is applied in the direction of unmanned aircraft, rotorcraft, cutting tools, etc., can solve the problems of high risk, casualties, low efficiency, etc., to ensure flight quality, excellent lift performance, wing The effect of type relative thickness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

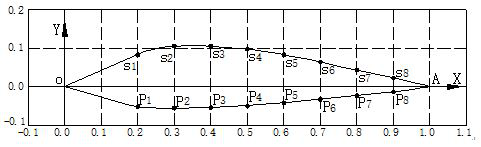

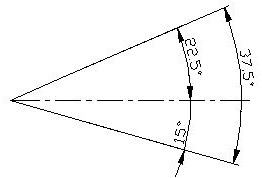

[0033] like Figure 4 and Figure 5 As shown, the present invention is a cutting-wing rotor shape for a picking drone, including a blade shape and a cutting airfoil, which is mainly improved for the standard airfoil of an existing agricultural drone; The cutting airfoil at the end of the blade shape can cut the branches and realize the fruit drop, and at the same time ensure the stable lift brought by the blade; the blade shape includes the cutting section, the transition from the blade end to the blade root in sequence section, main lift section and root reinforcement section, such as Figure 4 E-D, the cutting section is 100%-80% of the span direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com