Carton folding robot and folding method thereof

A technology of robots and cartons, applied in paper/cardboard containers, containers, papermaking, etc., can solve problems such as high space requirements, difficulty in affording machine costs for small and medium-sized enterprises, and additional handling procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] like Figure 1-Figure 3 As shown, the carton folding robot of the present invention includes a dual-arm robot, a driven first manipulator 1, a second manipulator 2 and an auxiliary back cover tooling 3, and the first manipulator 1 and the second manipulator 2 are installed on the arms respectively. The driving arm of the robot is used to drive the movement of the first manipulator and the second manipulator, and the auxiliary back cover tooling 3 is located below between the first manipulator 1 and the second manipulator 2;

[0056] The second manipulator 2 includes a second mounting substrate 4 connected to the robot, a suction cup assembly mounted on the second mounting substrate 4, an auxiliary positioning mechanism and a closing mechanism, and the auxiliary positioning mechanism is used for positioning and clamping the carton, so The closing mechanism is used to close the left bottom plate and the right bottom plate of the bottom surface of the carton, wherein the a...

Embodiment 2

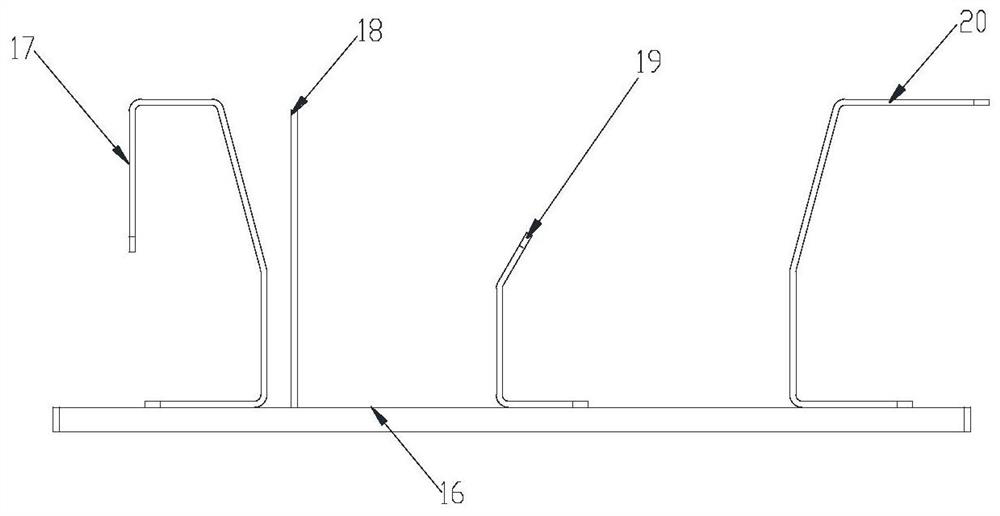

[0071] On the basis of Example 1, such as Figure 4 As shown, the first manipulator 1 in the carton folding robot of the present invention includes a first installation substrate 27 connected to the robot, a gripping mechanism for grabbing cartons and an ejection mechanism for opening and folding cartons , one side of the first mounting substrate 27 is installed with the gripping mechanism, and the other side is installed with the ejection mechanism, wherein: the gripping mechanism includes a rotating cylinder 24, a suction cup mounting plate 21 and a suction cup, and the rotating Cylinder 24 is installed on the described first mounting base plate 27, and the output end of described rotary cylinder 24 is connected with suction cup mounting plate 21, and described suction cup is installed in the bottom of suction cup mounting plate 21 for grabbing folding carton; The ejector mechanism includes a straight-travel cylinder 26 and a roller assembly. The straight-travel cylinder 26 ...

Embodiment 3

[0083] On the basis of Example 2, such as Figure 5-Figure 7 As shown, the bottom surface of the carton includes a front base plate, a rear base plate, a left base plate and a right base plate, a socket is formed on the rear base plate, and a tongue matched with the rear base plate is formed on the front base plate.

[0084] Utilize the folding method of the carton folding robot described in embodiment 2, comprise the following steps:

[0085] (1) The suction cup of the first manipulator 1 grabs the carton in the folded state on the feeding station (the folded carton is in a horizontal state, and 4 suction cups grab the rear side panel of the carton ( Figure 5The opposite side of the front side plate 36), such as Figure 5 shown);

[0086] (2) The rotary cylinder 24 drives the suction cup of the first manipulator 1 to rotate 90°, so that the carton in the horizontal state rotates in a vertical state. At this time, the left side plate 31 and the right side plate of the carto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com