Split type sliding block structure under stroke limit

A technology of stroke limitation and slider, which is applied in the field of split slider structure, can solve the problems of small core-pulling space and unable to complete manual core-pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

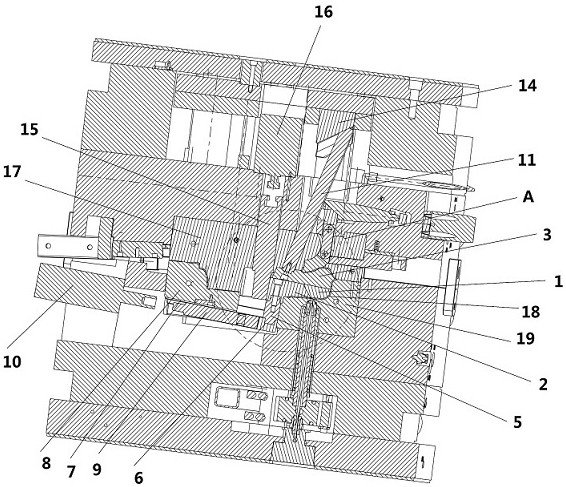

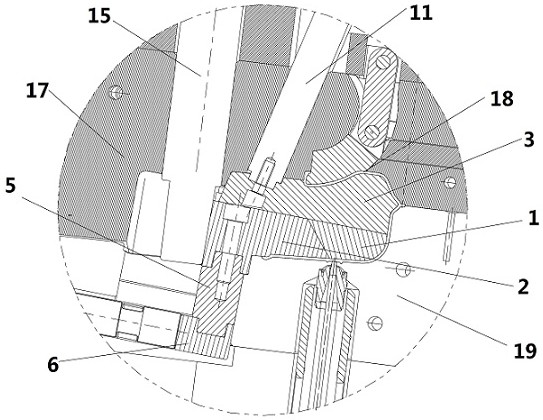

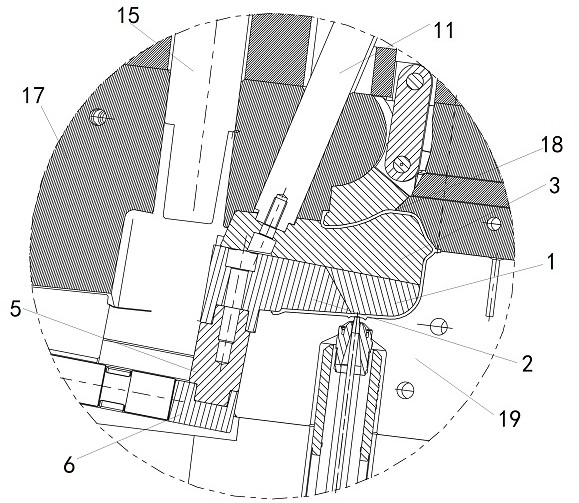

[0044] combined with Figure 1-14 , a split slider structure under stroke limitation in this embodiment, including a slider head 1, a slider 2, an inclined head 3, a slider connecting seat 5, a front mold slider seat 6, a driving connecting rod 9, a A driving member 10, inclined ejector rod 11, inclined ejector seat 14, wedging block 15 and second driving member 16, the slider head 1 and the slider 2 are slidably connected by the second dovetail groove 21, and the slider head 1 and the slider 2 are slidingly connected with the inclined head 3 through the first dovetail groove 20, one end of the slider connecting seat 5 is fixedly connected with the slider 2, and the other end of the slider connecting seat 5 is connected with one end of the front mold slider seat 6 Fixedly connected, the other end of the front mold slider seat 6 is fixedly connected with one end of the driving connecting rod 9, the other end of the driving connecting rod 9 is fixedly connected with the first dr...

Embodiment 2

[0047] combined with Figure 11 and 12 , a split slider structure under stroke limitation in this embodiment, compared with the technical solution of Embodiment 1, further includes a limit clamp 4, the limit clamp 4 includes a protrusion 41 and a groove 42, the The protrusion 41 is provided on the side where the slider head 1 is connected to the slanting head 3 or the side where the slanting head 3 is connected to the slider 2 and the slider head 1, and the groove 42 is located on the side where the slanting head 3 is connected to the slider 2 and The side where the slider head 1 is connected or the side where the slider head 1 is connected to the inclined head 3 .

[0048] There are four identical grooves 42 or protrusions 41 arranged on the side of the inclined plug 3 connected with the slider 2 and the slider head 1 , which are evenly arranged at both ends of the inclined plug 3 . Two identical protrusions 41 or grooves 42 are provided on the side where the slider head 1 ...

Embodiment 3

[0050] combined with Figure 10-12 , a split slider structure under stroke limitation in this embodiment, compared with the technical solution of Embodiment 1 or 2, the side of the inclined head 3 connected to the slider 2 and the slider head 1 is provided with the first A dovetail groove 20 matches the rib 31 .

[0051] The shape of the dovetail groove is ∠, and the convex strip 31 matches the first dovetail groove 20 and can slide in the first dovetail groove 20 without falling out. During the first core-pulling process and the second core-pulling process, the first dovetail groove 20 acts as a guide, and the convex strip 31 slides in the first dovetail groove 20 . During the third core-pulling process, the first dovetail groove 20 acts as a fixed connection, and due to the fixing effect of the limit clip 4, the convex strip 31 will not slide in the first dovetail groove 20, so that the slider head 1 follows the inclined head. 3 Do ejection exercise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com