Continuous catalytic hydrogenation equipment and continuous catalytic hydrogenation method for pyridine compounds

A catalytic hydrogenation and pyridine technology, applied in pressure vessels, organic chemistry, sampling devices used in chemical processes, etc., can solve problems such as effective control of difficult catalytic effects, and achieve the effect of optimizing catalytic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

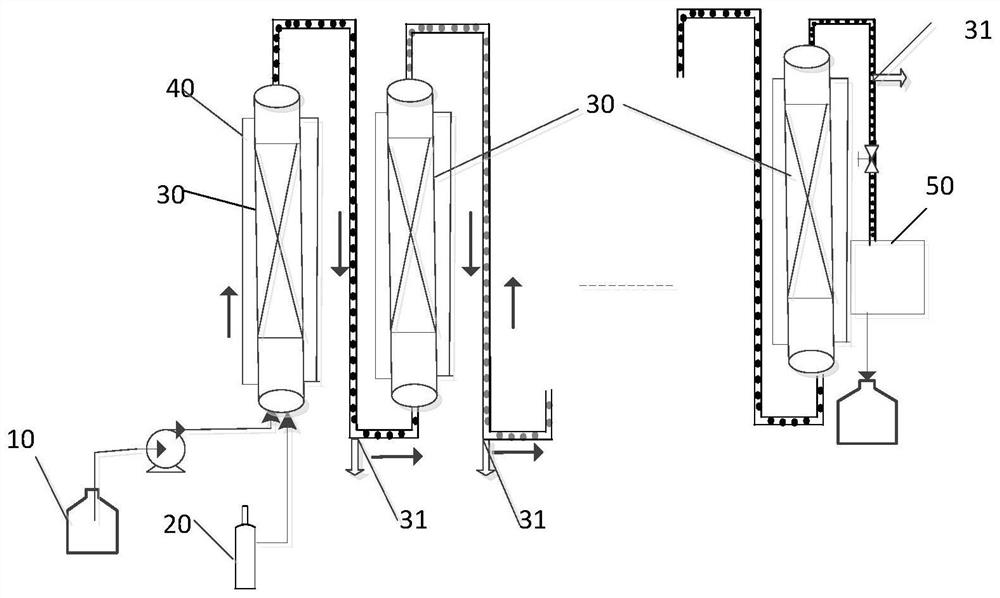

[0039] The structure of continuous catalytic hydrogenation equipment is as follows figure 1 As shown, the 4-stage fixed-bed reactors 30 are used in series, and the materials are fed from the bottom to the top. 200 g of raw material 2-picoline was dissolved in 800 g of methanol for use, and was pumped into the first-stage fixed bed reactor 30 by means of a feed pump. The length-diameter ratio of the fixed-bed reactors 30 at all levels is 80. The fixed-bed reactors 30 are filled with 5 g of spherical rhodium-carbon with a particle size of 3 mm and a loading of 5% as a catalyst. Above and below the catalyst, three spherical particles of 3 mm are laid. Alumina was used as a filler, and nitrogen was used to purge the series-connected fixed-bed reactors 30 for 0.5 h. At the same time, the external bath temperature of the heat-exchange jackets 40 of each fixed-bed The heat exchange medium is heat transfer oil, which is supplied by bottom-in and top-out type. During the heating proc...

Embodiment 2

[0041] The structure of continuous catalytic hydrogenation equipment is as follows figure 1 As shown, the 4-stage fixed-bed reactors 30 are used in series, and the materials are fed from the bottom to the top. 200 g of 2-picoline was dissolved in 800 g of methanol for later use. The length-diameter ratio of the fixed-bed reactors 30 at all levels is 80. The fixed-bed reactors 30 are filled with 5 g of spherical rhodium-carbon with a particle size of 3 mm and a loading of 5% as a catalyst. Above and below the catalyst, three spherical particles of 3 mm are laid. Alumina was used as a filler, and nitrogen was used to purge the series-connected fixed-bed reactors 30 for 0.5 h. At the same time, the external bath temperature of the heat-exchange jackets 40 of each fixed-bed The heat exchange medium is heat transfer oil, which is supplied by bottom-in and top-out type. During the heating process, the fixed bed reactor 30 device was purged with hydrogen. After the heating is comp...

Embodiment 3

[0043] The structure of continuous catalytic hydrogenation equipment is as follows figure 1 As shown, the 4-stage fixed-bed reactors 30 are used in series, and the materials are fed from the bottom to the top. 200 g of 2-picoline was dissolved in 800 g of methanol for later use. The length-diameter ratio of the fixed-bed reactors 30 at all levels is 80. The fixed-bed reactors 30 are filled with 5 g of spherical rhodium-carbon with a particle size of 3 mm and a loading of 5% as a catalyst. Above and below the catalyst, three spherical particles of 3 mm are laid. Alumina was used as a filler, and nitrogen was used to purge the series-connected fixed-bed reactors 30 for 0.5 h. At the same time, the external bath temperature of the heat-exchange jackets 40 of each fixed-bed The heat exchange medium is heat transfer oil, which is supplied by bottom-in and top-out type. During the heating process, the fixed bed reactor 30 device was purged with hydrogen. After the heating is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com