Method for manufacturing magnet module

A technology of a magnet module and a manufacturing method, which is applied in the field of manufacturing magnet modules, can solve the problems of reduced operation efficiency, cumbersomeness, and many operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, a method of manufacturing a magnet module according to the present invention will be described in detail based on the drawings.

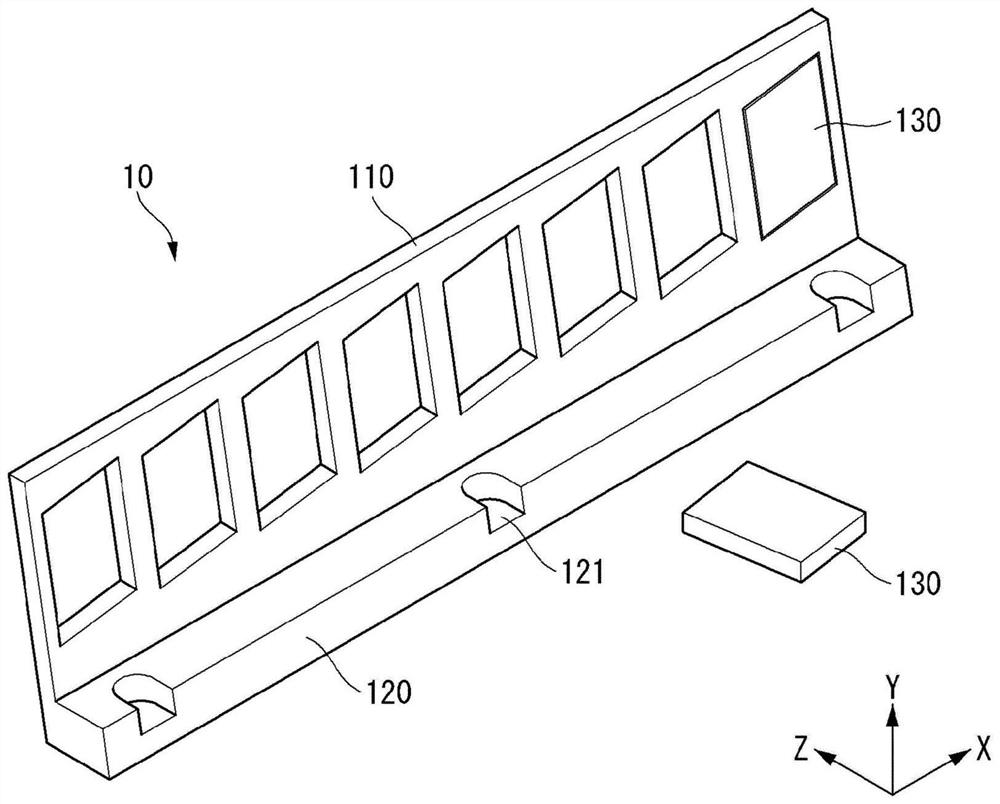

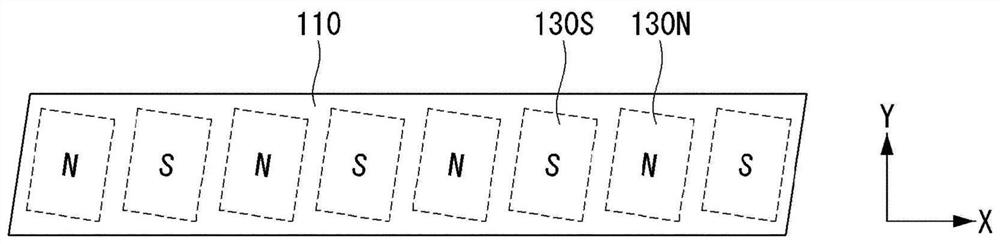

[0038] In the present invention, after injection-molding a magnet module including a plurality of unmagnetized magnets, magnetizing the magnets mounted on the magnet module with a magnetizer can manufacture a figure 1 Similar magnet modules for linear motors.

[0039] figure 2 shows a magnet module produced by injection molding according to an embodiment of the invention, image 3 show figure 2 The frame of the permanent magnet is fixed in the magnet module, and two or more magnet modules can be continuously arranged along the forward (traveling) direction of the mover.

[0040] The magnet module 10 may be composed of a frame 110 for installing a plurality of permanent magnets 130 and a base 120 formed with a hole 121 for combining with a stator, and the frame 110 and the base 120 are integrally formed by injection molding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com