Method and device for detecting wire ingots and wire ingot sorting system

A silk spindle and target detection technology, which is applied in the silk spindle sorting system and the detection of silk spindles, can solve the problems of missed detection, low detection efficiency, false detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

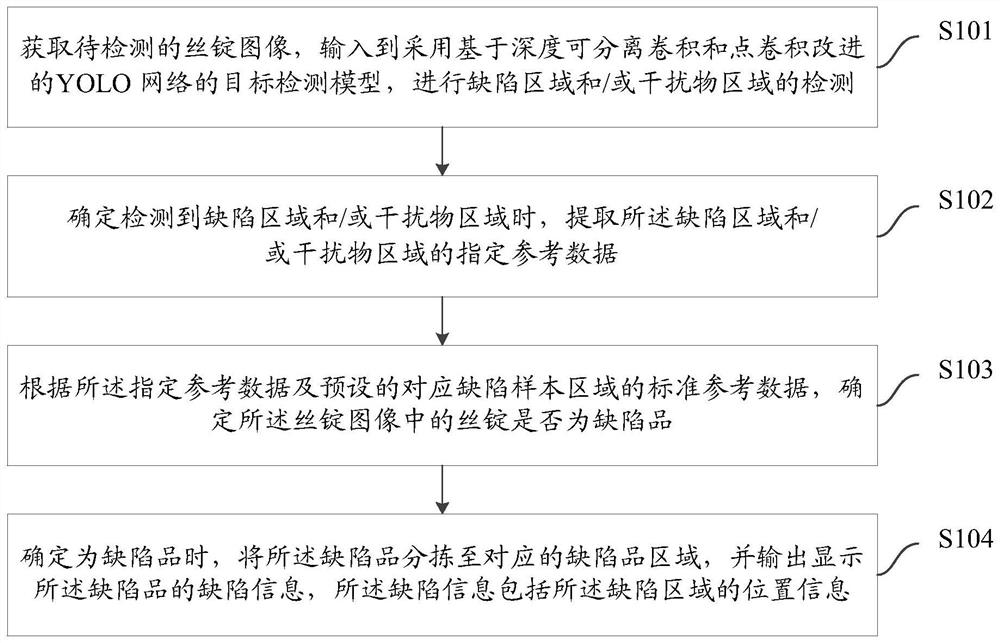

[0101] The embodiment of the present invention provides a method for detecting silk ingots, which is applied to the online detection scene of silk ingots on production lines, such as figure 1 As shown, the method includes:

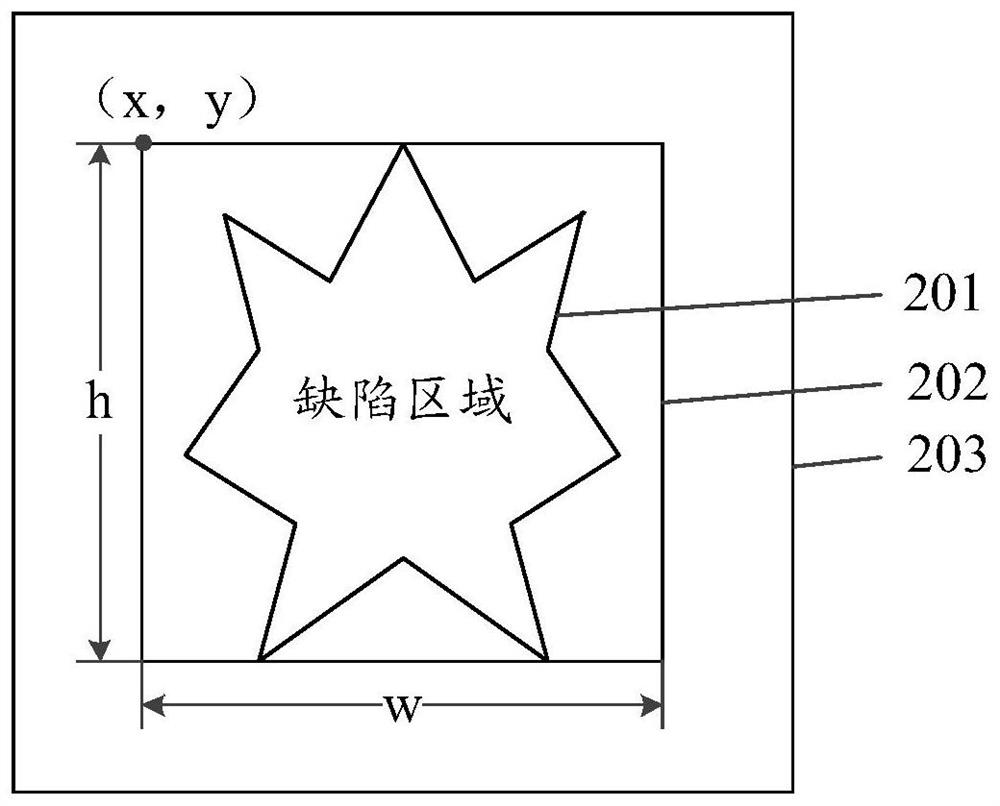

[0102] Step S101: Obtain an image of the to-be-detected silk spindle, and input it into the target detection model using the improved YOLO network based on depth separable convolution and dot convolution to detect defective areas and / or interference areas;

[0103] In the embodiment of the present invention, when acquiring the image of the silk spindle to be inspected, the image of the silk spindle on the production line can be synchronously acquired online, so that the silk spindle on the production line can be detected online, or the pre-collected silk spindle image can be obtained asynchronously. Detection.

[0104] After acquiring the image of the filament to be detected, input the image of the filament into the target detection model of the YOLO network impr...

Embodiment 2

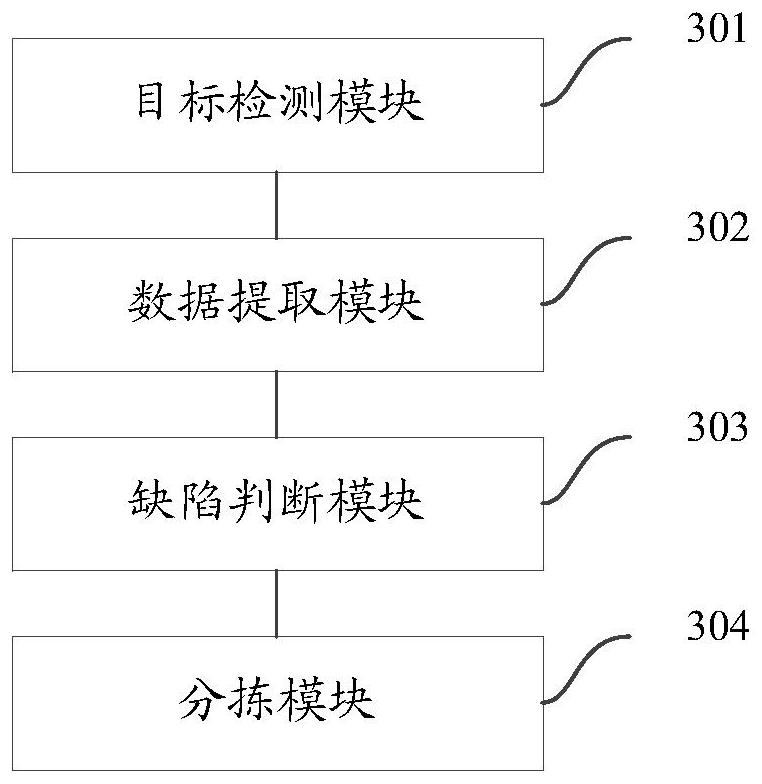

[0167] The method for detecting silk ingots in the present invention is described above, and the device for detecting silk ingots that performs the above method is described below.

[0168] See image 3 , The embodiment of the present invention provides a device for detecting silk spindles, including:

[0169] The target detection module 301 is used to obtain the image of the silk spindle to be detected, and input it into the target detection model of the YOLO network improved based on depth separable convolution and dot convolution to detect the defect area and / or the interference area;

[0170] The data extraction module 302 is configured to extract designated reference data of the defect area and / or the interference area when the defect area and / or the interference area are detected;

[0171] The defect judgment module 303, according to the designated reference data and preset standard reference data corresponding to the defect sample area, determines whether the silk spindle in the...

Embodiment 3

[0193] See Figure 4 , Another embodiment of the device for detecting silk in the embodiment of the present application includes:

[0194] Processor 401, memory 402, transceiver 409 and bus system 411;

[0195] The memory is used to store programs;

[0196] The processor is used to execute the program in the memory and includes the following steps:

[0197] Obtain the image of the to-be-detected silk ingot and input it into the target detection model of the YOLO network improved based on depth separable convolution and dot convolution to detect the defect area and / or the interference area;

[0198] When it is determined that the defect area and / or the interference area is detected, extract the designated reference data of the defect area and / or the interference area;

[0199] Determine whether the silk spindle in the silk spindle image is a defective product according to the designated reference data and the preset standard reference data corresponding to the defect sample area;

[0200] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com