Online sealing detection device and method

A detection device and detection method technology, which can be applied in the direction of using liquid/vacuum degree for liquid tightness measurement, by measuring the increase and deceleration rate of fluid, etc., which can solve the problem of lack of online detection method and device for tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

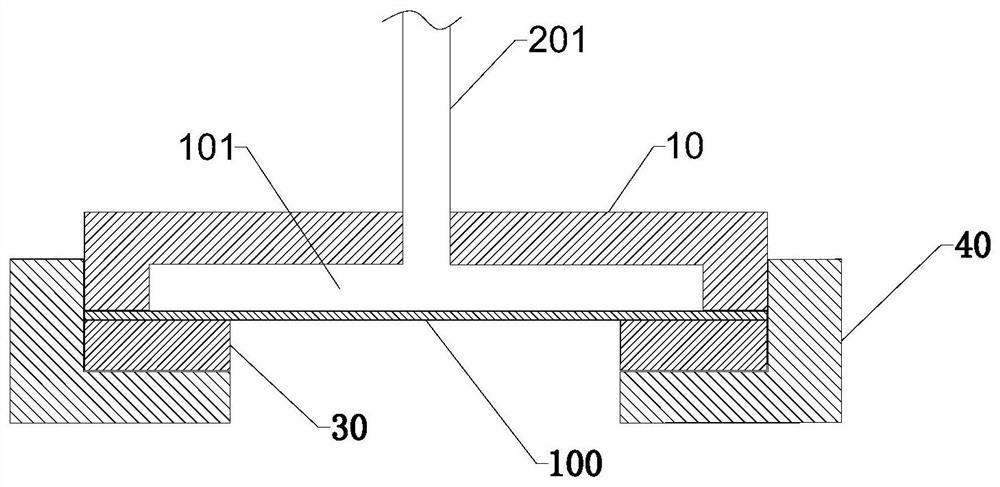

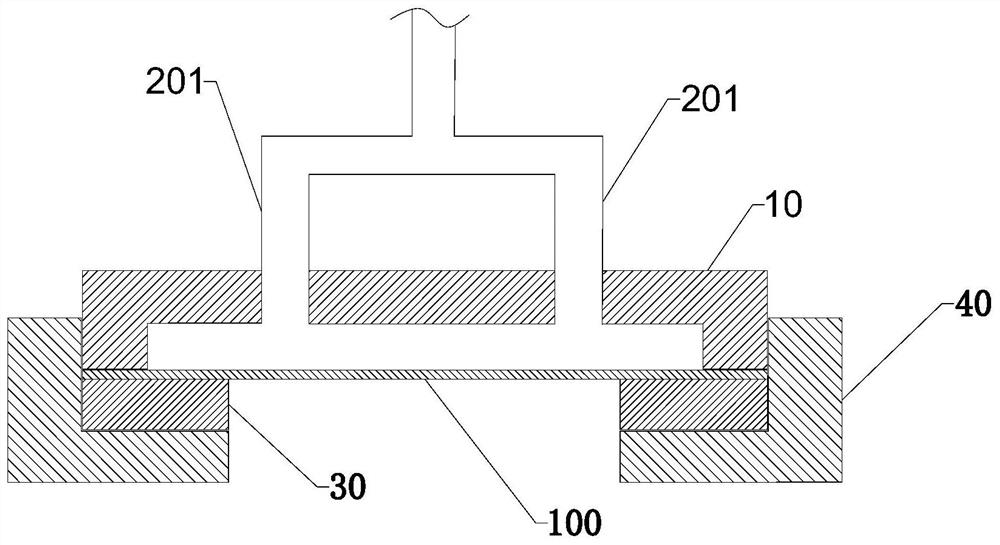

[0053] Such as Figure 1~2 As shown, the present embodiment provides a sealing on-line detection device for detecting the sealing of the element under test 100, which includes: a cover plate 10, a measuring device and a seal 30, and the element under test 100 is arranged on the cover plate 10 and seal 30;

[0054] The cover plate 10 is arranged on the upper surface of the component under test 100, and the cover plate 10 is provided with a groove, and the groove and the component under test 100 form a cavity 101; those skilled in the art can determine the size of the groove in the cover plate 10 according to the actual situation. Shape and size, for example, a cylindrical or nearly cylindrical cavity 101 is formed in this embodiment. Specifically, the cavity 101 has a diameter of 80 mm and a height of 1.6 mm, and the cavity 101 is coaxial with the device under test 100 . The size of the cylinder can be determined by those skilled in the art according to the actual situation, f...

Embodiment 2

[0068] This embodiment provides an on-line airtightness detection device. Compared with embodiment 1, the on-line airtightness detection device uses a first gas flow meter to replace the first air pressure gauge in embodiment 1, and a second gas flow meter to replace the implementation In the second barometer of Example 1, the measuring device detects the gas flow rate of the cavity 101 . All the other parts are the same as in Example 1.

Embodiment 3

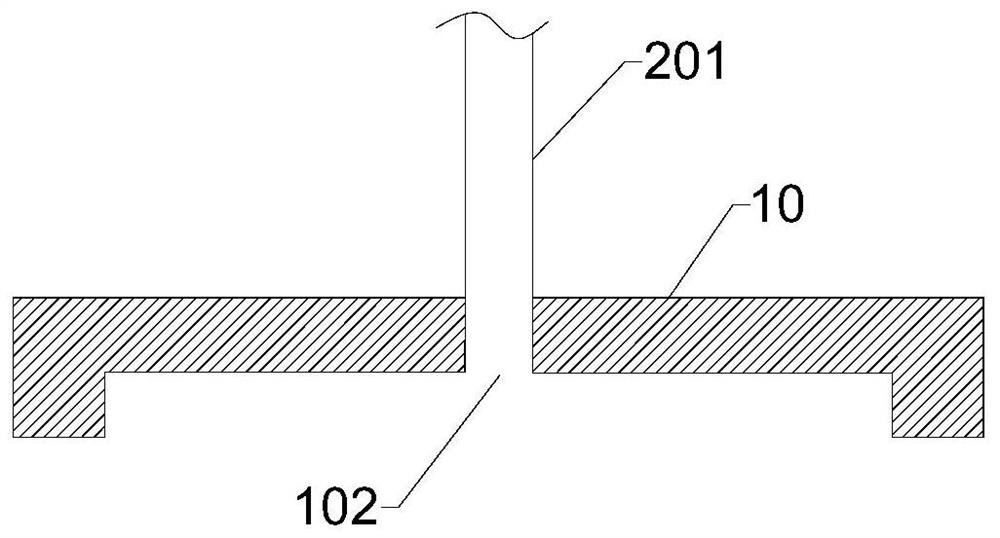

[0070] Such as image 3 As shown, this embodiment provides an on-line airtightness detection device. Compared with Embodiment 1, there are two air inlets 102 of the on-line airtightness detection device, and correspondingly, there are two gas passages 201, two The gas channel 201 is finally merged into one main gas channel 202 to reduce the number of channels, and the gas is supplied by the same gas supply source. The first air pressure gauge and the second air pressure gauge are all arranged on the merged main gas channel 202, and the remaining components are the same as Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com