Electromagnetic valve high-dynamic high-frequency response control method based on voltage pulse width modulation technology

A technology of pulse width modulation and control method, which is applied to valve details, valve devices, engine components, etc., and can solve the problems of reducing the dynamic characteristics of solenoid valves, complex system operating conditions, and reducing the dynamic characteristics of the closing phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

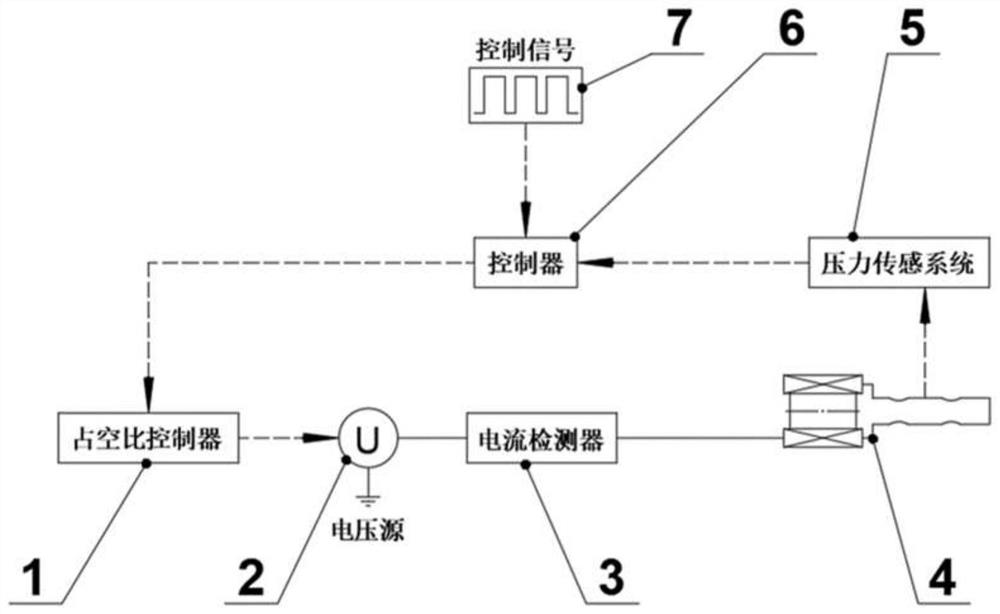

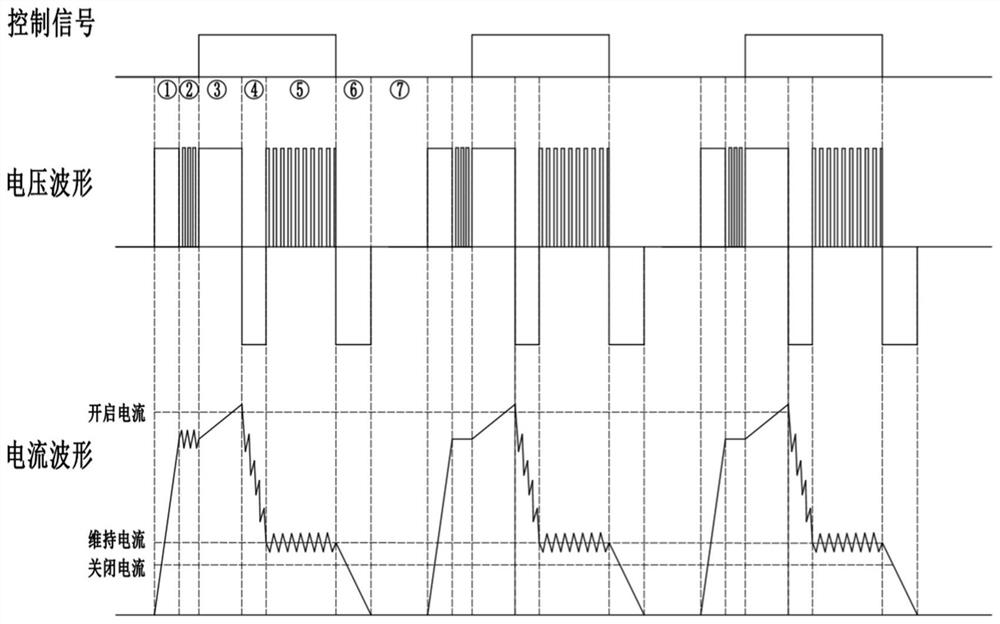

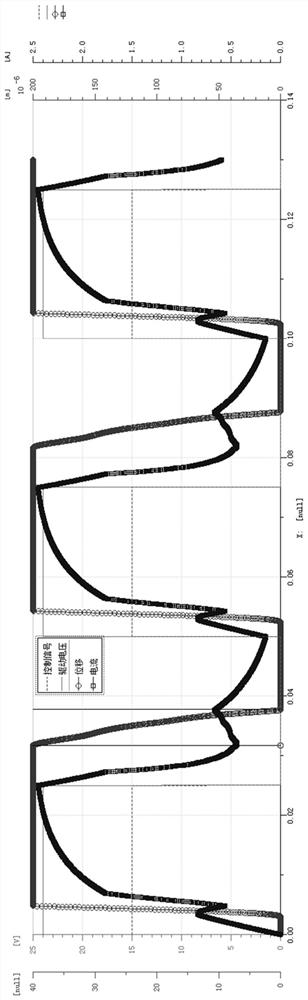

[0035] like figure 1 As shown, the method of the present invention is based on figure 1 The high dynamic and high frequency response driving system of the solenoid valve based on the voltage pulse width modulation technology shown, the driving system includes a duty ratio controller 1, a voltage source 2, a current detector 3, a solenoid valve 4, and a pressure sensing system 5. Controller 6; pressure sensing system 5 is connected to each working port of solenoid valve 4 to obtain the pressure state of each working port of solenoid valve in real time; controller 6 is connected to pressure sensing system 5 to obtain data in pressure sensing system 5 in real time , the controller 6 can calculate the system turn-on current and turn-off current in the current state according to the data obtained, the controller includes a control signal generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com