Loading pressure-flow compensation balance valve

A technology of flow compensation and load pressure, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc. It can solve the problems of complex product structure, ineffective compensation effect of hydraulic power compensation balance valve, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

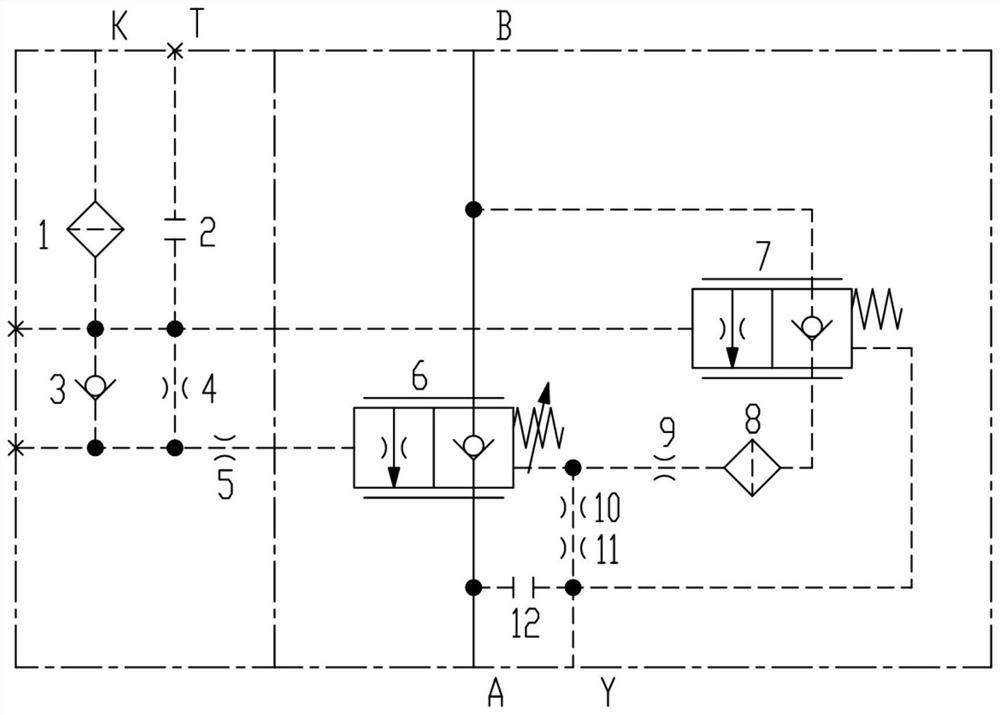

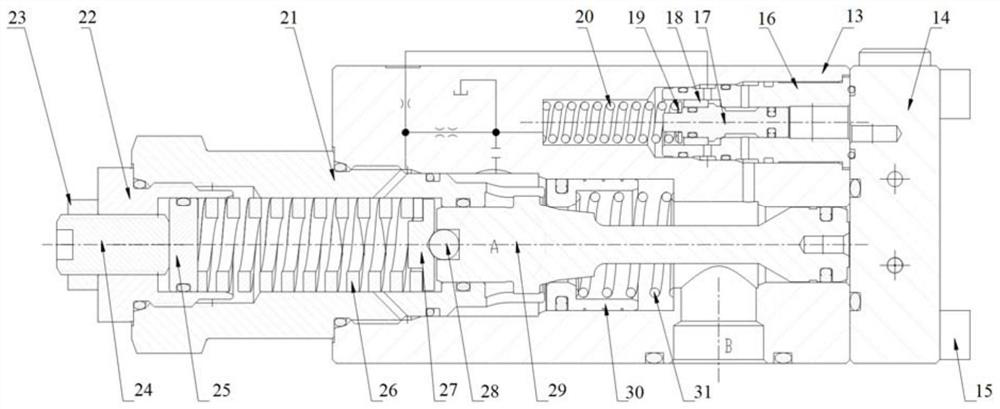

[0022] Such as figure 1 and figure 2 As shown, the present invention discloses a load pressure-flow compensation balance valve. The load pressure-flow compensation balance valve is composed of a control end cover 14 and a balance valve body assembly. The control end cover is composed of the first filter screen 1, the first screw plug 2, the one-way valve 3, the first damper 4 and the second damper 5; , the second filter screen 8, the third damper 9, the fourth damper 10, the fifth damper 11 and the second screw plug 12.

[0023] The control pressure from the luffing drop is connected to the K port of the control end cover 14, and the K port of the control end cover 14 passes through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com