Excavating, supporting and anchoring combined unit drilling rig attitude adjusting and anchor net laying device and method

A combined unit and bolter technology, applied in the direction of supporting devices, drilling equipment, cutting machinery, etc., can solve problems such as poor coordination, poor operation safety, drill pipe swing and eccentric load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

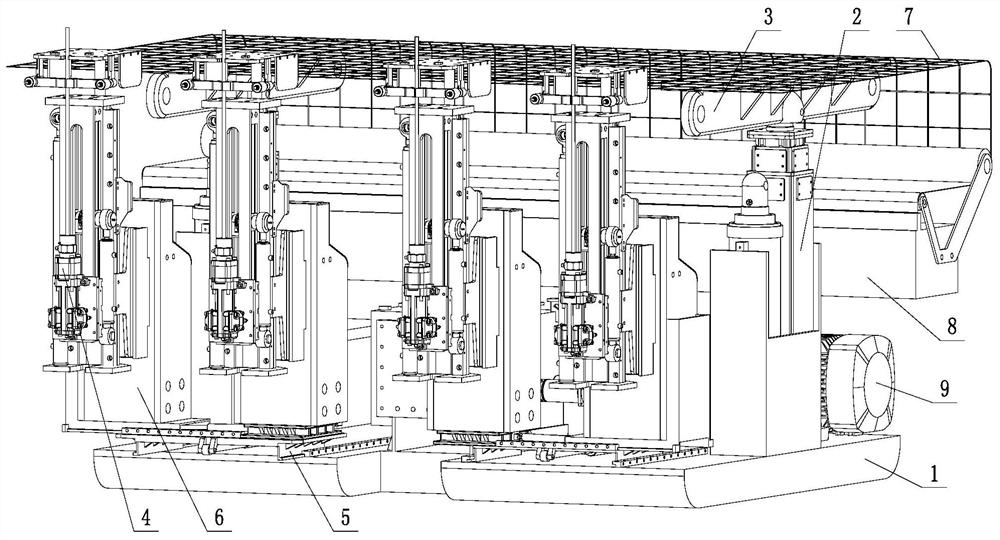

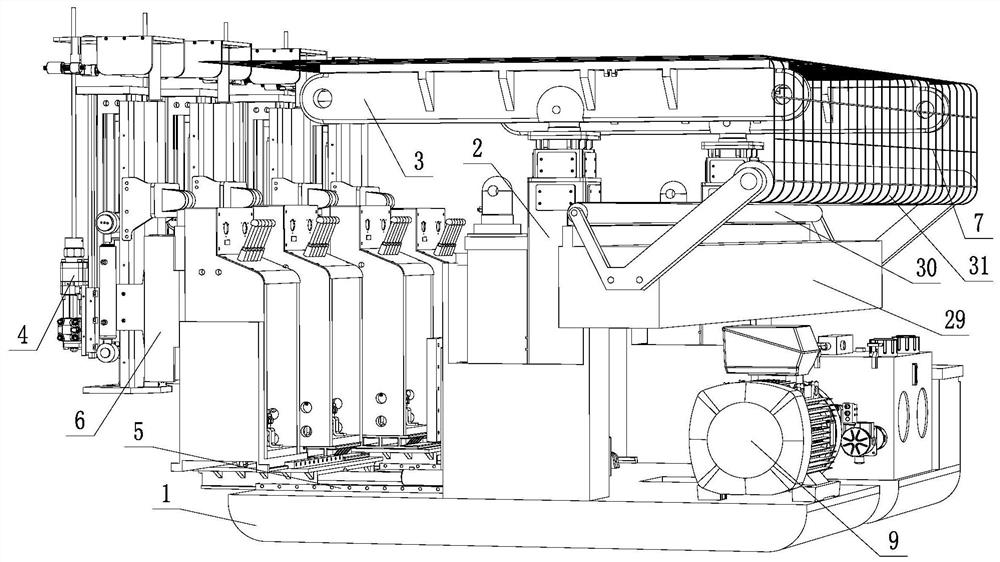

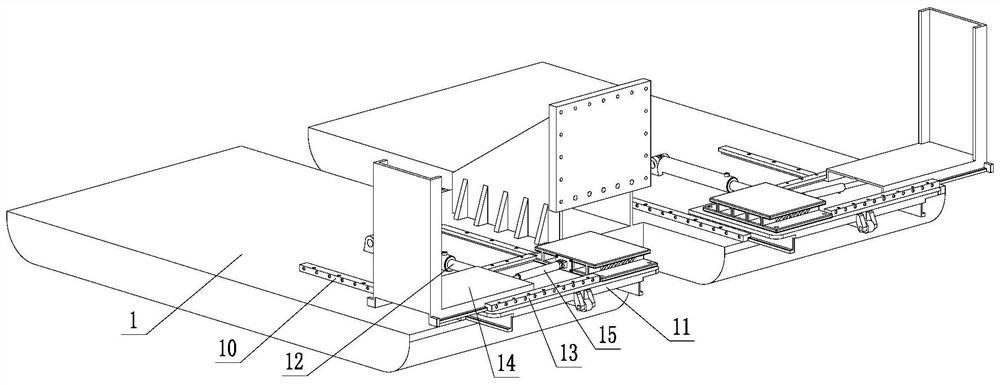

[0027] Such as Figure 1~5 As shown in the figure, a drilling rig attitude adjustment and anchor net laying device of a combined excavation, support and anchor unit includes a base sliding shoe 1, a support column 2, a support longitudinal beam 3, a bolter rig 4, a drilling rig horizontal attitude adjustment component 5, the height and angle of the drilling rig Attitude adjustment assembly 6, anchor net 7 and anchor net laying assembly 8; the base slide shoe 1 is located behind the roadheader of the excavation, support and anchor unit, the base slide shoe 1 is hinged with the body tail of the roadheader, and the base slide shoe 1 is connected to the The body of the roadheader is followed; the support column 2 is fixed vertically in the middle of the base shoe 1, and the support longitudinal beam 3 is fixed horizontally on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com