Installation method of basket diagonal draw bar type cantilever frame

An installation method and a technology of inclined rods, which are applied in the field of cantilever frames, can solve the problems of large amount of repair work for scaffold holes, leakage of outer walls, and poor passage of operators at stairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

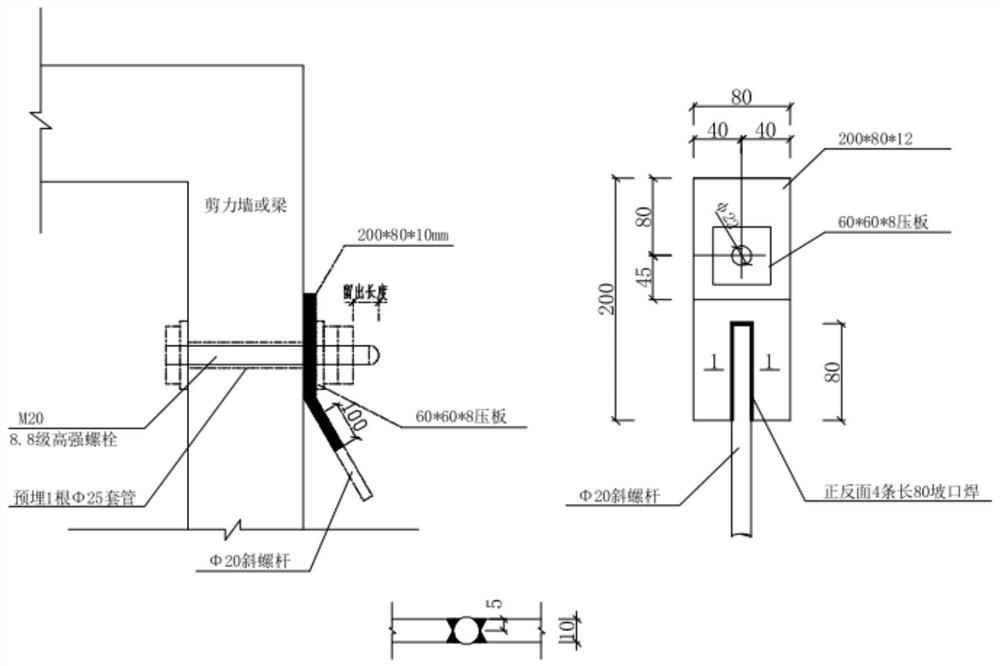

[0046] The installation method of the flower basket diagonally-stayed rod-type suspension frame, the installation method includes the following steps:

[0047] The first step is to set up preparations;

[0048] The second step is the production of cantilever frame materials;

[0049] The third step is to check the material of the cantilever frame;

[0050] The fourth step is to bury the casing of the wall ring beam;

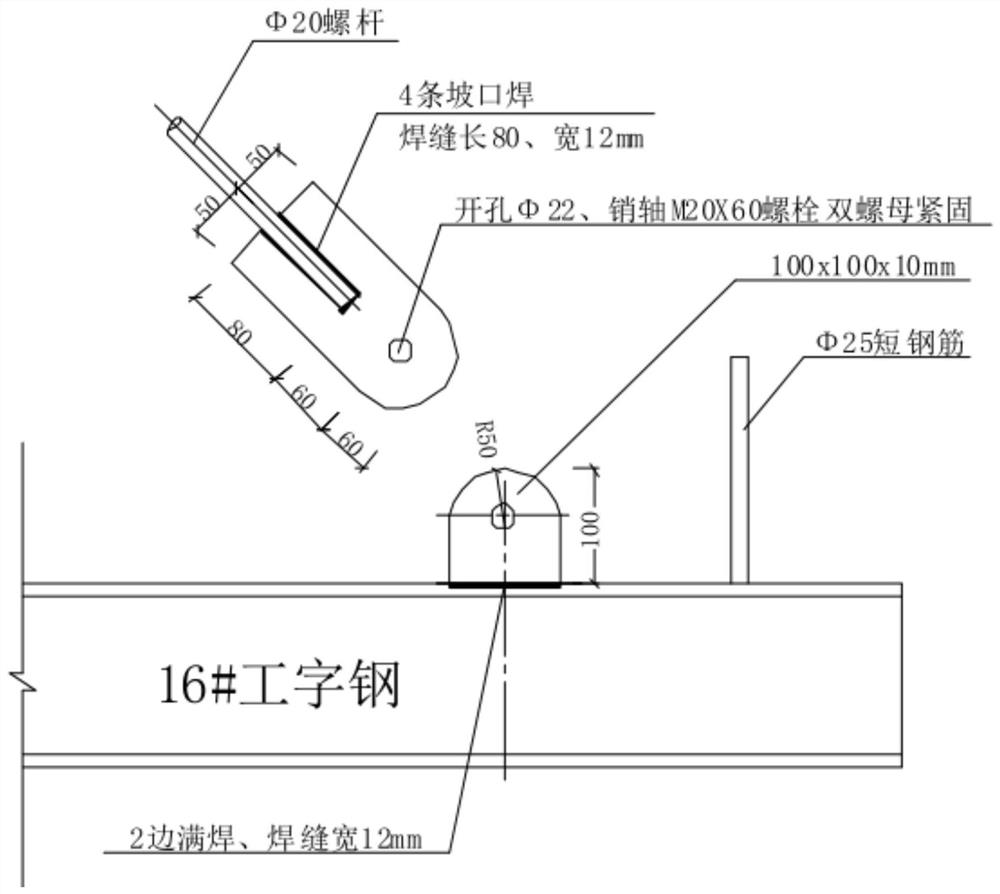

[0051] The fifth step is to install the cantilevered I-beam cantilever;

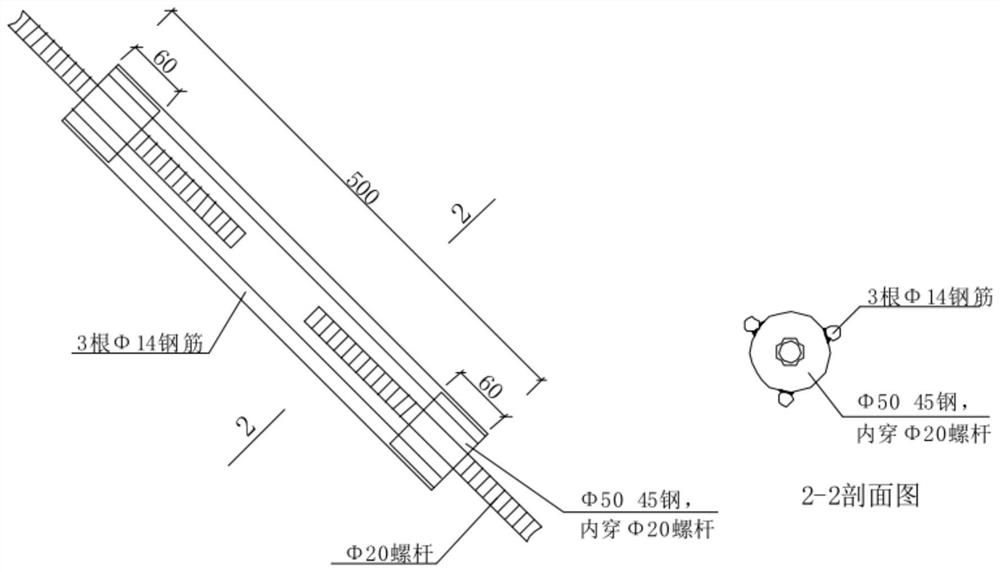

[0052] The sixth step is the setting of the cantilevered I-beam pull-up rod;

[0053] The seventh step is to set the positioning point of the pole;

[0054] The eighth step, scaffolding sweeping rod erection;

[0055] The ninth step is to install the scaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com