Clothing treatment device

A technology for clothes processing equipment and air ducts, which is applied to household clothes dryers, separation methods, filtration and separation, etc., and can solve the problems of filter blockage, lack of aesthetic feeling, and affecting drying efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

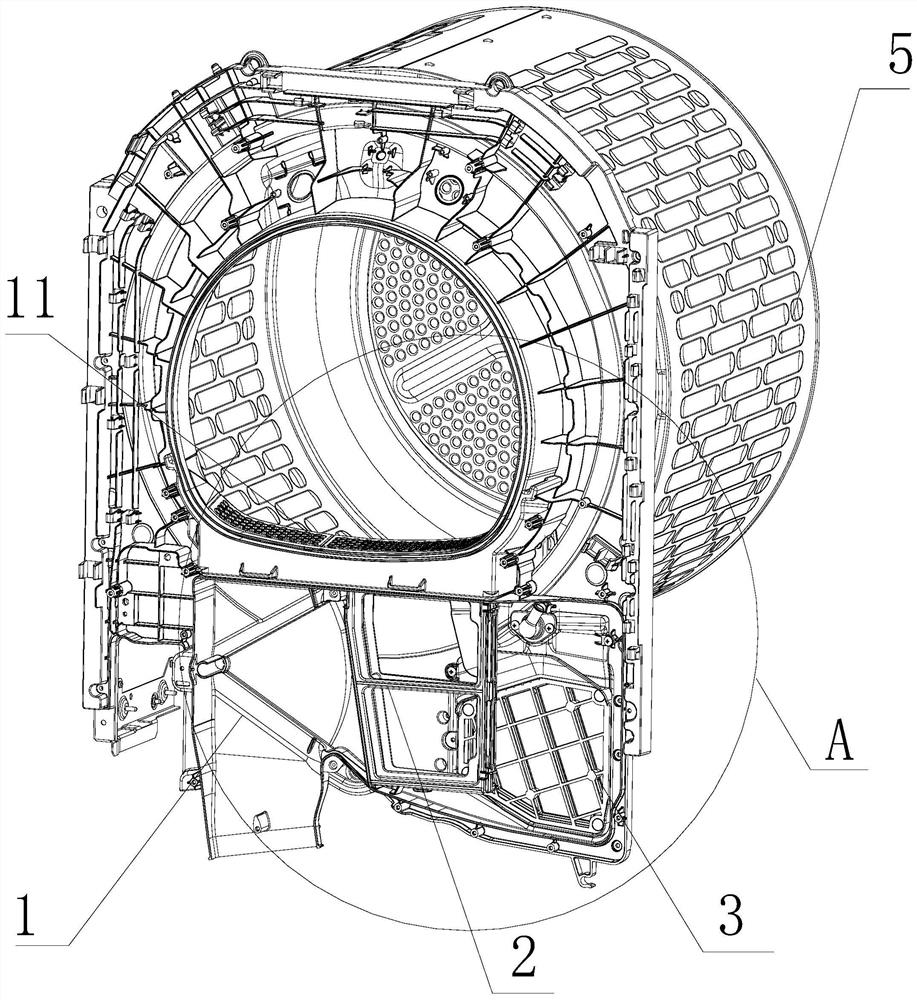

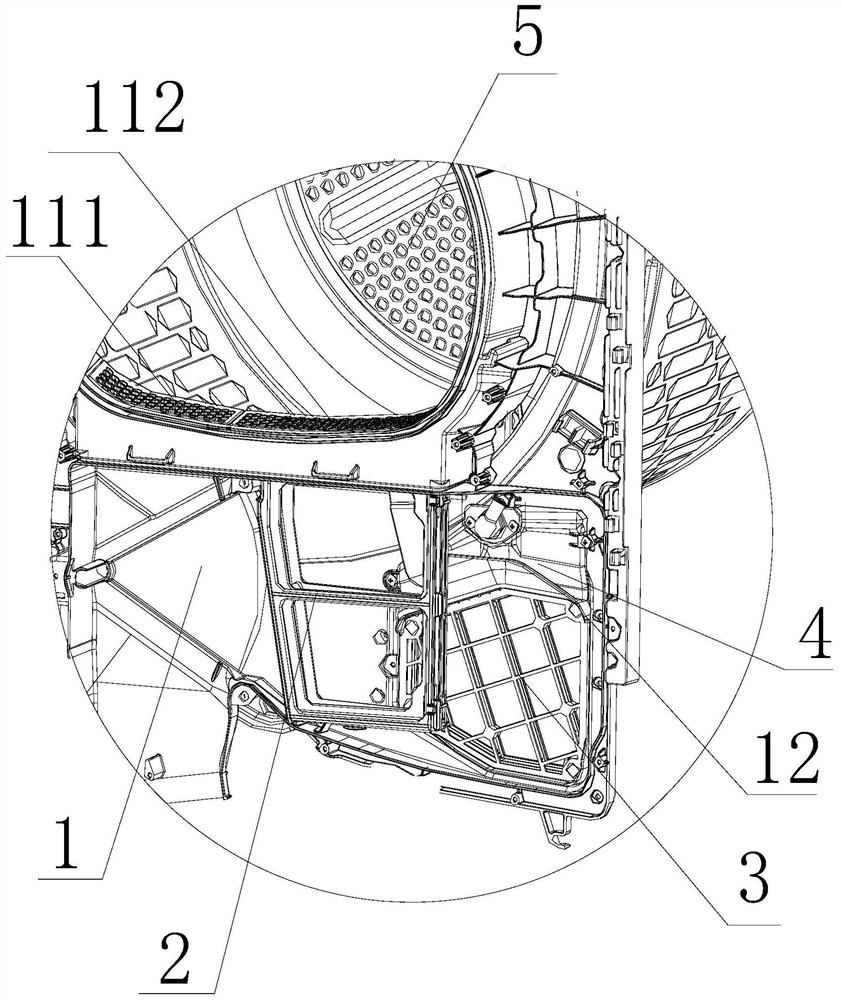

[0047] Such as Figure 1-5 As shown, this implementation provides a laundry treatment device. The laundry processing equipment is a clothes dryer or an integrated washing and drying machine, including a first filter 3, and the first filter 3 includes a filter body 32, and the filter body 32 is provided with a handle 31 and is used to communicate with the water spray. The device 4 cooperates with a water flow distributing part for receiving and distributing water flow.

[0048] By setting the handle 31, it is convenient for the user to pick and place the first filter 3, and the water flow distribution part is set to receive the water sprayed by the water spray device 4, and the water flow is evenly distributed to clean the entire mesh surface of the filter.

[0049] The filter body 32 includes a frame 321 on which a filter screen 322 is installed, and the water flow distribution part includes a water flow distribution plate 33 located above the filter screen 322 on the frame 3...

Embodiment 2

[0057] see Figure 1-5 As shown, this implementation provides a laundry treatment device. The laundry processing equipment is a clothes dryer or an integrated washing and drying machine, and includes a first filter, and the first filter 3 includes a filter body 32, and the filter body 32 is provided with a handle 31 and is used to communicate with the water spray device. 4 Cooperate with the water flow distribution part that receives and distributes water flow. By providing the handle part 31 , it is convenient for the user to pick and place the first filter 3 .

[0058] Specifically, an installation part 12 is provided in the drying air duct, and the first filter 3 is inserted through the air inlet 11 of the drying air duct so that the filter body 32 is fixed on the installation part 12, and the handle part 31 is extended from the installation part 12 to the air inlet 11 of the drying air duct.

[0059] The handle part 31 is extended from the installation part 12 to the ai...

Embodiment 3

[0070] The third embodiment describes in detail the scheme for realizing water spray cleaning on the basis of the first and second embodiments above.

[0071] A water spraying device 4 is arranged in the drying air duct, and the installation part 12 is arranged within the water spraying range of the water spraying device 4 , and the water spraying device 4 can spray water to realize automatic cleaning of the first filter 3 .

[0072] Specifically, the water spray device 4 is arranged on the upper part of the first filter 3 , and the sprayed water flows down to flush the first filter 3 . The cleaning device includes a liquid inlet, a nozzle, and a diversion channel connecting the two, and the cleaning water introduced into the water spray device 4 from the liquid inlet flows out from the nozzle after flowing through the diversion channel to rinse the filter. device, so that the lint attached to the filter screen 322 is washed away by the washing liquid, and the washing liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com