Intelligent air-jet textile machine serging device

A textile machine and edge locker technology, which is applied in textiles, fabric edge trimming, textiles, and papermaking, and can solve problems such as bottlenecks in production efficiency and inability to meet the maximum speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

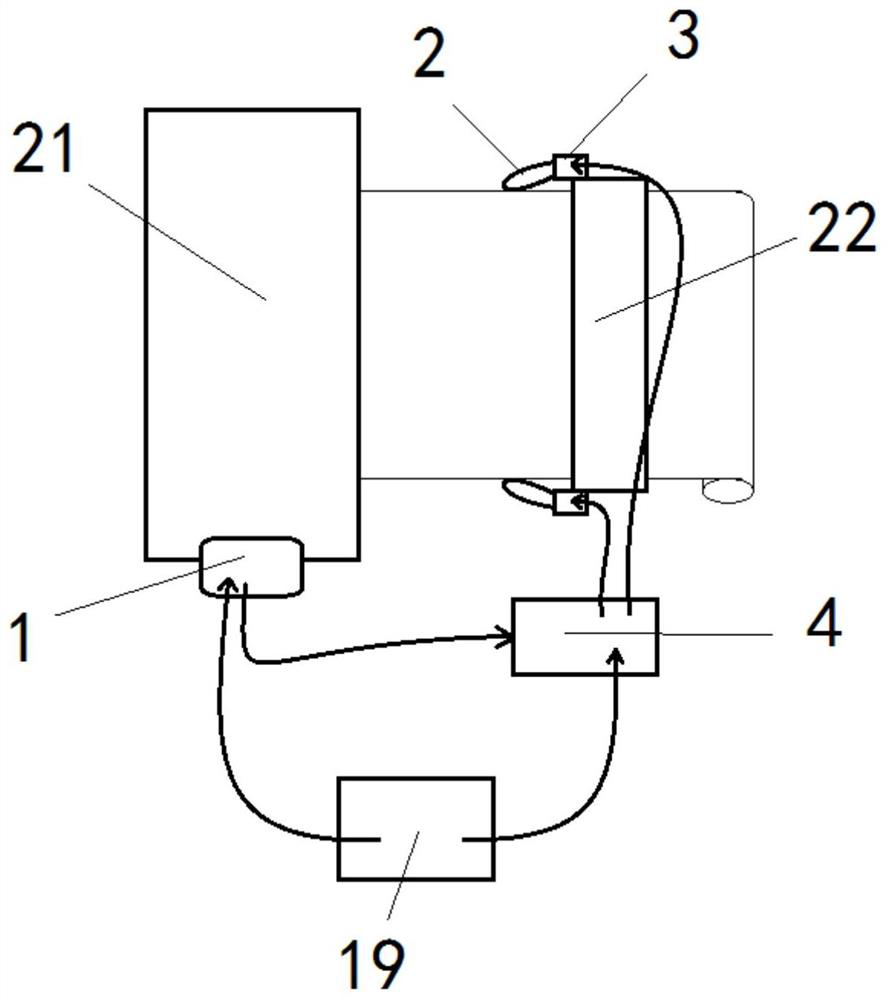

[0017] according to figure 1 , figure 2 , image 3 , Figure 4 As shown, an intelligent air-jet textile machine 21 edge locker includes a PLC controller 1 for controlling the work of the air-jet textile machine 21, and also includes: a heating head 2, which is arranged on the said heating head 2 through a fixing seat 3 Both sides of the discharge port 22 of the air-jet textile machine 21; a power module 4, the output end of the power module 4 is electrically connected to the heating head 2, and the input end of the power module 4 is connected to the power supply 19; the power module 4. The communication port is electrically connected to the signal output port of the PLC controller 1, and is used to output a constant current to the output terminal according to the signal of the PLC controller 1.

[0018] In the above setting, the heating head 2 is realized by a plastic electric heating wire. Therefore, on the basis of the fixed seat 3 being fixed, by bending the heating hea...

Embodiment 2

[0020] The fixing seat 3 is provided with a channel 5 passing through both sides, and an electric conductor 6 is arranged in the channel 5, and the input end of the heating head 2 extends to the inside of the channel 5 through any end of the fixing seat 3, And electrically connected with the electrical conductor 6 ; the end of the electrical conductor 6 away from the heating head 2 is electrically connected with the output end of the power module 4 through a high temperature wire 7 .

[0021] In this setting, the fixing seat 3 is made of high-temperature-resistant ceramics, and the heating head 2 and the electric conductor 6 in the fixing seat 3 are detachably connected, so as to meet the seaming requirements of different positions and materials, and the electric conductor 6 As an intermediate piece, it is connected between the high temperature wire 7 and the heating head 2, which not only plays a role of heat insulation, but also facilitates the replacement of the heating head...

Embodiment 3

[0023] The cross-section of the channel 5 is arranged in an inverted trapezoidal shape, and the bottom of the cross-section of the channel 5 is in a circular groove structure; the top of the electrical conductor 6 is in a flat plate structure, and is arranged parallel to the top of the channel 5; the electrical conductor 6 has two The areas near the two ends are respectively provided with folded edges 8 which are folded downwards, and the bottom ends of the folded edges 8 are arranged with serrated teeth 9; There is a fixing hole penetrating to the outside of the fixing seat 3 , and a fixing screw 11 is fitted in the fixing hole, and the outer end of the fixing screw 11 is inclined to the corresponding end of the channel 5 .

[0024] In the above setting, the electrical conductor 6 is pressed by rotating the fixing screw 11, thereby forcing the electrical conductor 6 to apply pressure to the side wall of the channel 5 by the heating head 2 and the high-temperature wire 7, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com