Horizontal plug flow anaerobic reactor and treatment method for kitchen waste materials

An anaerobic reactor, kitchen waste technology, applied in biological material sampling method, biochemical equipment and method, gas production bioreactor, etc., can solve poor operation stability, bottom accumulation, top scum, tank Problems such as high construction cost and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described with reference to the accompanying drawings.

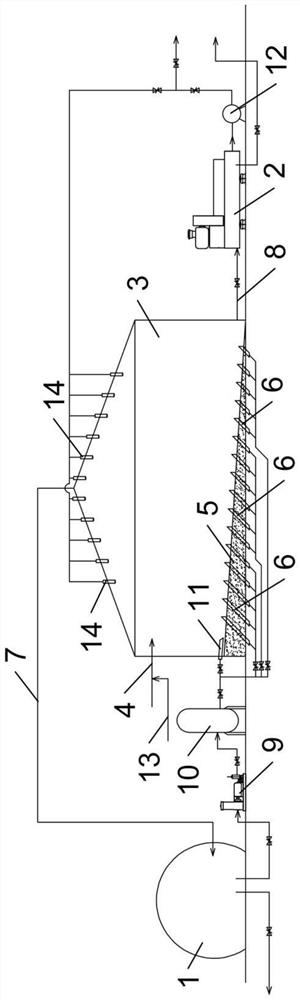

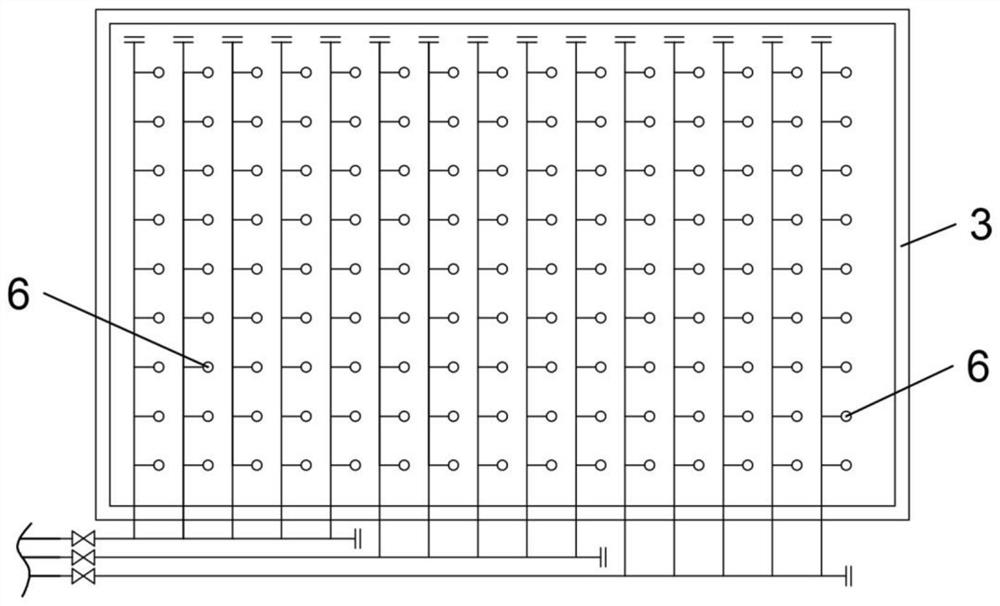

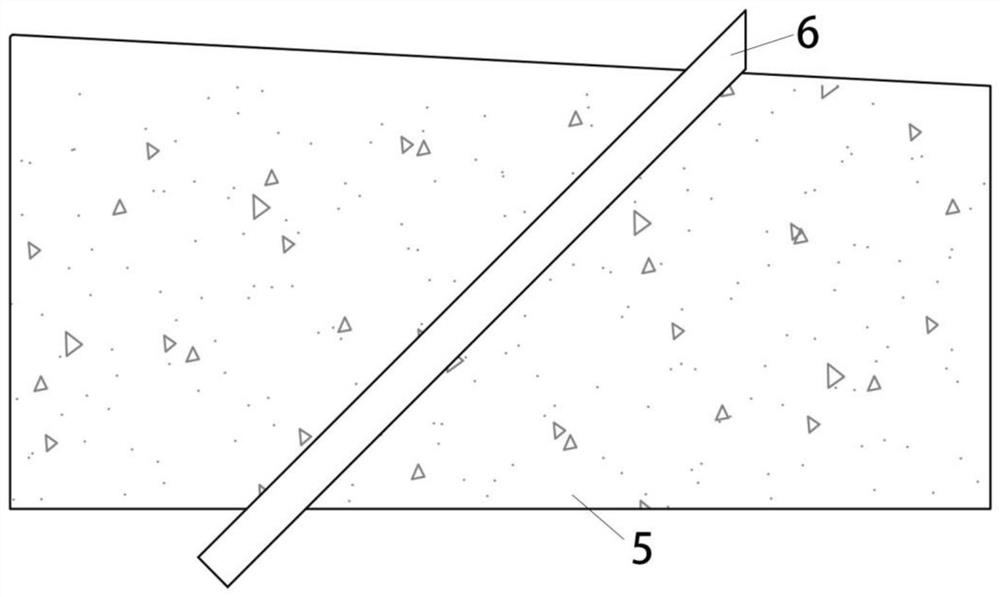

[0039] This embodiment discloses a horizontal plug-flow anaerobic reactor for kitchen waste materials, such as Figure 1~3 As shown, it includes a biogas tank 1, a dehydrator 2 and at least one anaerobic reaction tank; the anaerobic reaction tank includes a tank body 3, and the tank body 3 is a tank structure, and adopts carbon steel anticorrosion or steel concrete structure construction; The discharge direction is the front-to-back direction, and the tank body 3 is provided with a feed pipe 4 for passing materials into the tank body 3. The feed pipe 4 is connected with a steam pipe 13, and the steam enters the feed pipe 4 through the steam pipe 13 and is discharged. The material in the feed pipe 4 is heated, and the heated material enters the tank body 3 through the feed pipe 4; the bottom of the tank body 3 forms a slope structure 5, and the slope structure 5 is a concrete s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com