Acetylene generator

An acetylene generator and generator technology, applied in the field of acetylene generating equipment, can solve problems such as large energy consumption, low acetylene output, and complex structure of acetylene generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

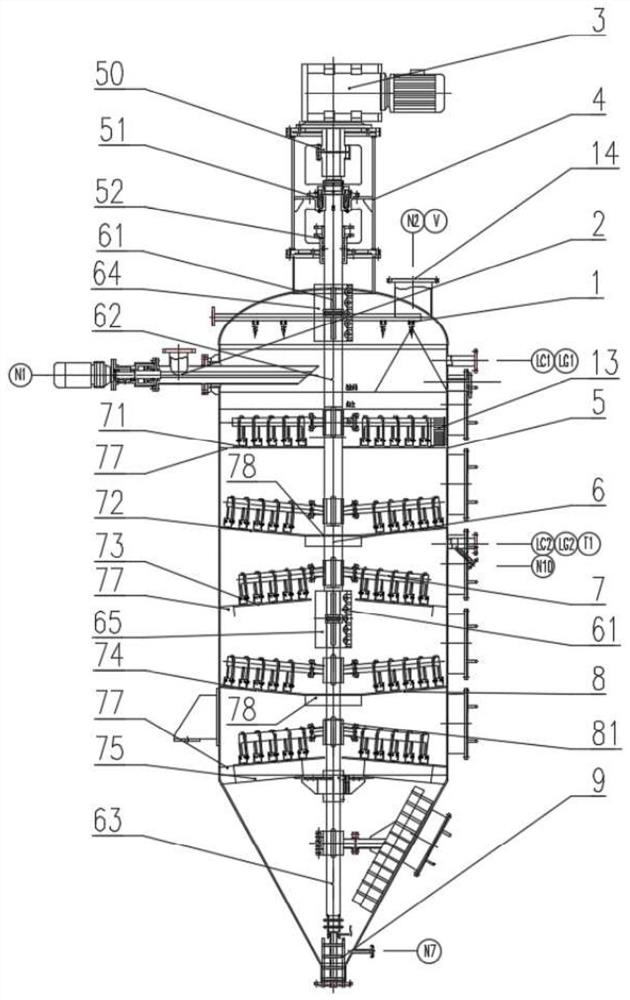

[0023] Such as figure 1 As shown, the embodiment of the present invention provides an acetylene generator, including a generator cylinder 5, which is mainly connected by the generator cylinder 5, the connecting frame 4, the stirring drive device 3, and the drive shaft 6 from top to bottom. The first material guide plate 71, the second material guide plate 72, the third material guide plate 73, the fourth material guide plate 74, the fifth material guide plate 75 and other components on the generator cylinder are composed.

[0024] The generator cylinder body 5 is arranged vertically, and a sealing feeder 2 is provided on one side thereof and adopts the way of flaring feeding, and a nozzle device 1 is arranged on the top of the generator cylinder body 5, and the nozzle device 1 is located at the first Above the material guide plate 71, in this embodiment, the nozzle device 1 is provided with 5 nozzles in total, and a temperature port (not shown), a pressure port (not shown), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com