Extrusion die for screw thread inner wall and method of improving fibrosis degree of thin film charge bar

A technology of extrusion die and thread, applied in the field of thread inner wall extrusion die, can solve the problems of difficult to guarantee the mechanical properties and uniformity of PTFE film, low degree of fibrillation of the material rod, disordered direction of fibrillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by giving an example and in conjunction with listed accompanying drawing, technical content of the present invention is specifically set forth, as follows:

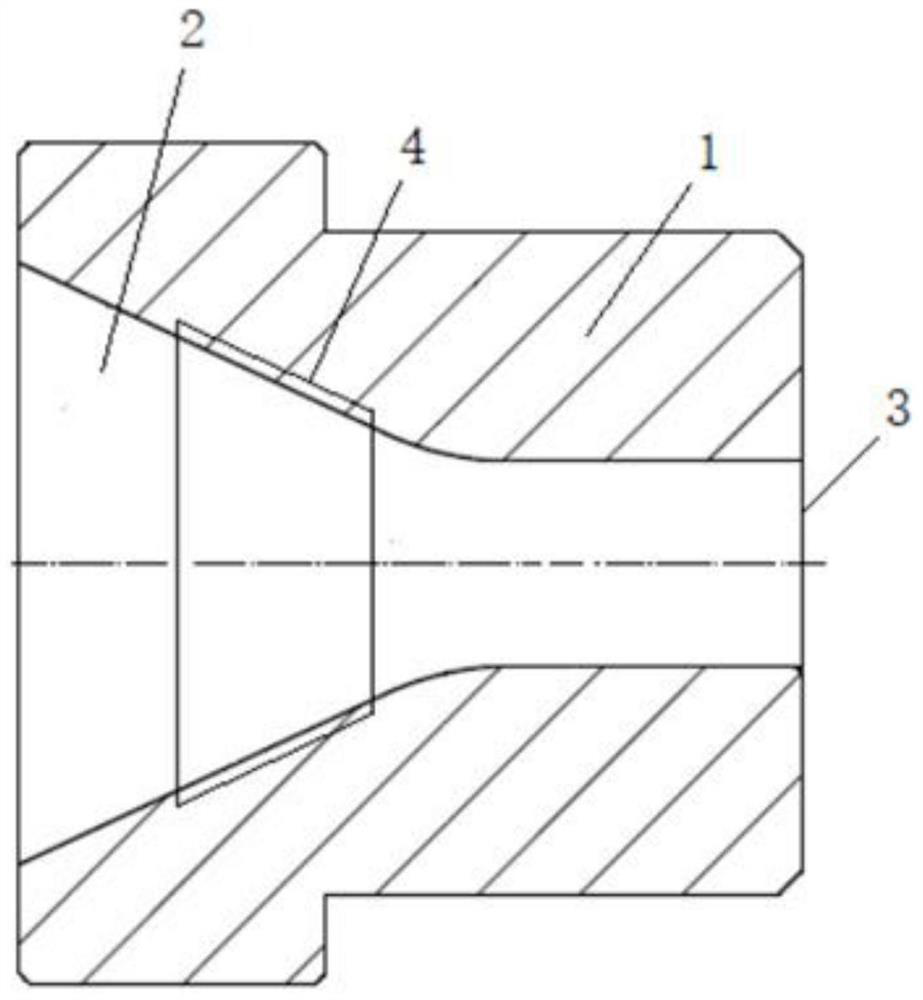

[0023] Such as figure 1 As shown, a threaded inner wall extrusion die includes a mold body 1, a tapered cavity 2 and an extrusion hole 3 are arranged in the mold body 1, and the small-diameter end of the tapered cavity 2 communicates with the extrusion hole 3, Different from conventional molds, threads 4 are provided on the inner wall of the tapered cavity 2 of the present invention, and the specifications of the threads 4 can be specifically set according to the performance requirements of the product.

[0024] Preferably, the depth direction of the thread 4 is perpendicular to the inner wall surface of the tapered cavity 2 .

[0025] Preferably, the inner diameter of the thread 4 is the same as the inner diameter of the tapered cavity 2, and the outer diameter is determined according to the degree of fibro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com