Method for rapidly preparing metal organic layer material and application

A metal-organic, layered material technology, applied in chemical instruments and methods, catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as low efficiency and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for rapidly preparing metal-organic layer materials of the present invention, comprising the following steps:

[0040]Take 140mg hafnium chloride HfCl 4 (0.438mmol) and 125mg 1,3,5-tricarboxyphenylbenzeneH 3 BTB (0.285mol), add 8.8mL of concentrated hydrochloric acid, 3mL of deionized water and 20mL of DMF, ultrasonically dissolve it fully, transfer it to a 100mL polytetrafluoroethylene-lined polyetheretherketone reactor, put it into a microwave reactor for 5 Heated to 90°C within 1 minute and kept for 1 hour to carry out the reaction. The white precipitated product was centrifuged, washed three times with DMF, absolute ethanol, and water, respectively, and vacuum-dried at 75°C for 24 hours to obtain the final metal-organic layer material. Specifically, it is a hafnium-based metal organic layer material. The resulting sample was designated as Hf-BTB-HCl.

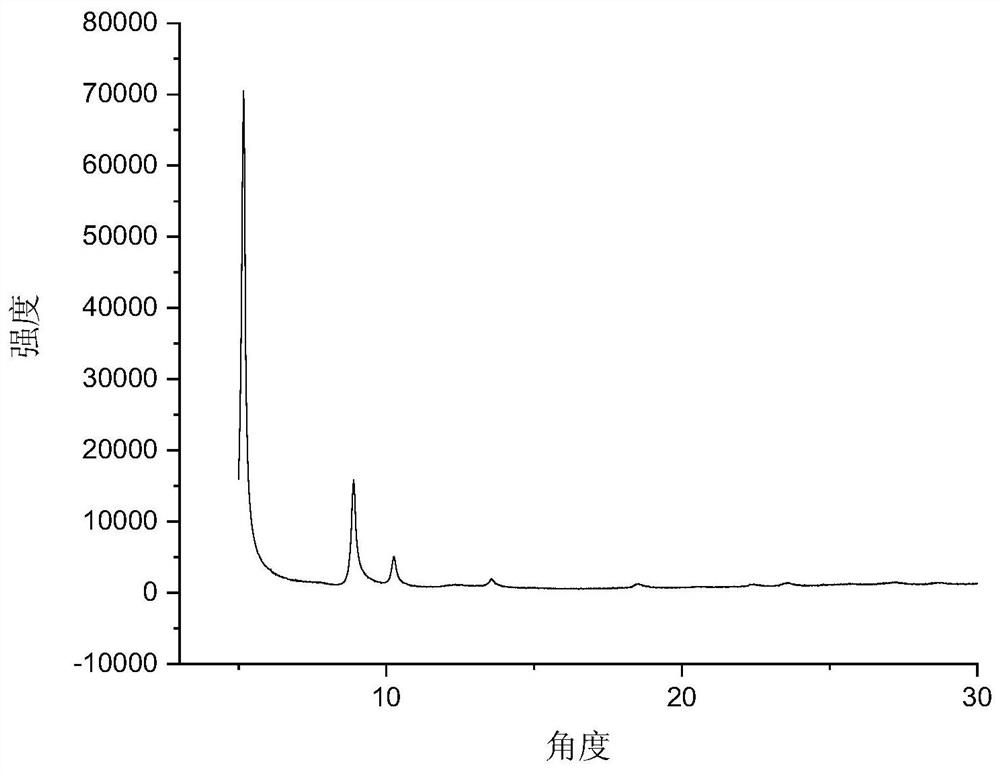

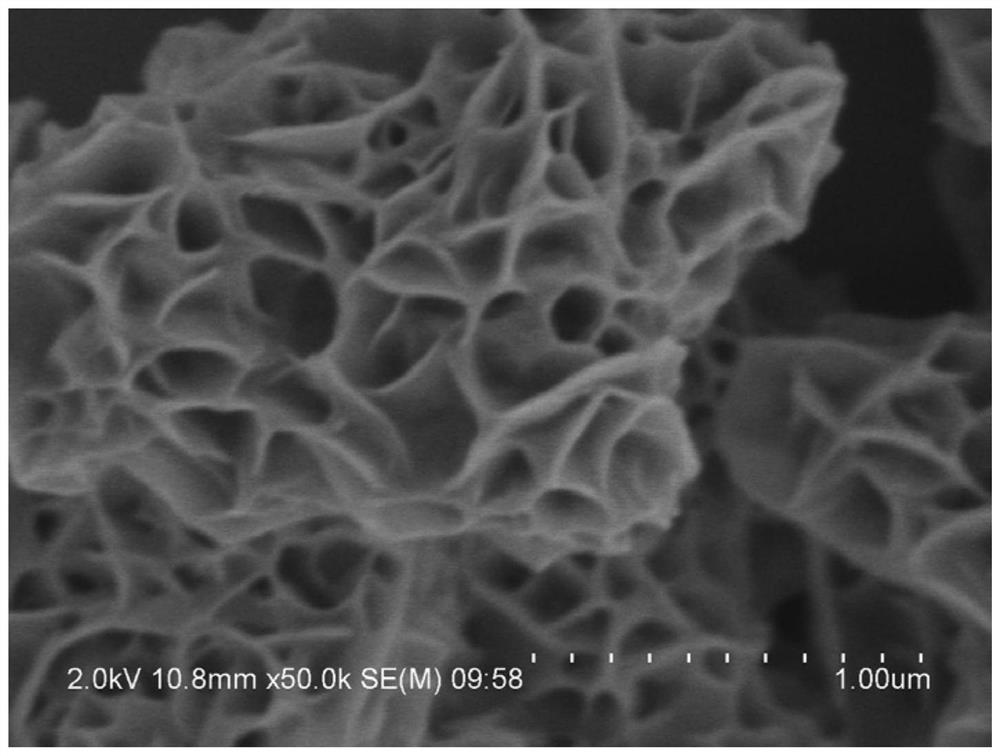

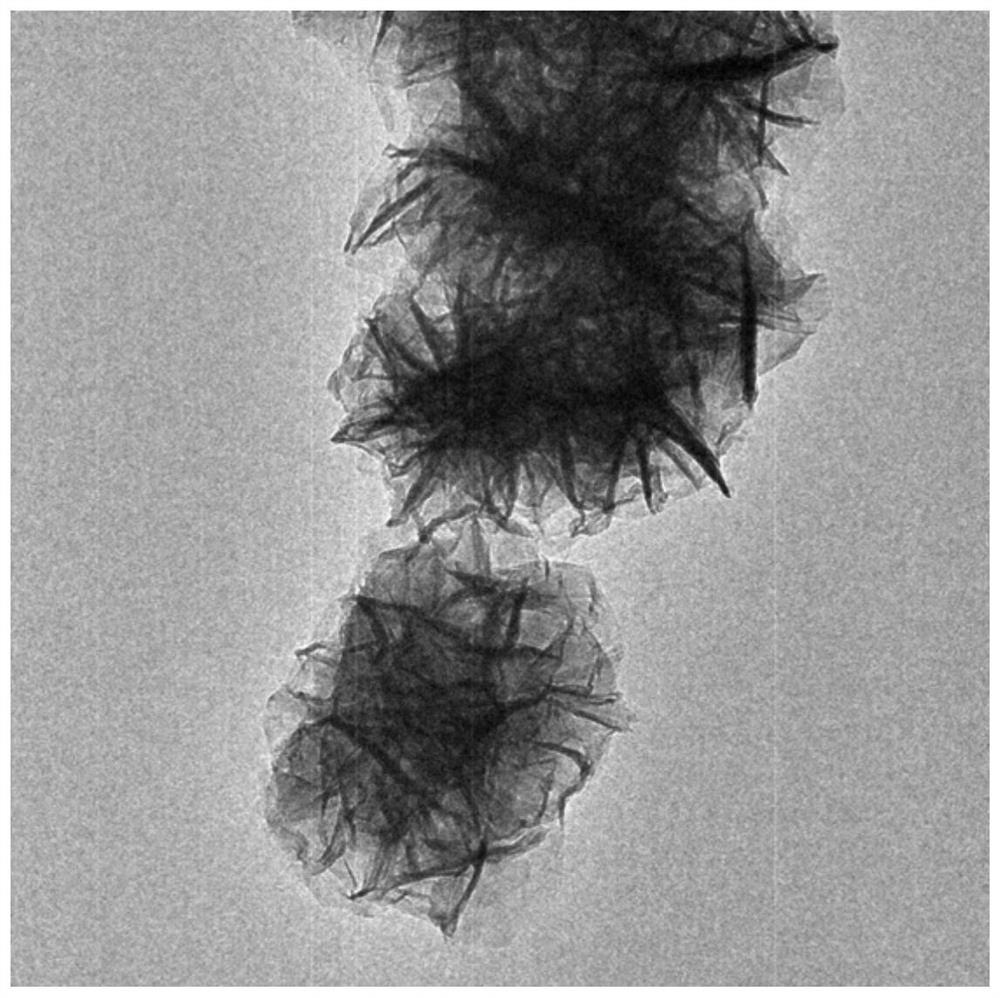

[0041] The product characterization data of this embodiment are as figure 1 , 2 , 3, 4, and 5. figur...

Embodiment 2

[0043] A method for rapidly preparing metal-organic layer materials of the present invention, comprising the following steps:

[0044] Take 116mg hafnium oxychloride HfOCl 2 (0.438mmol) and 125mg three (4-carboxyphenyl) -1,3,5-triazine H 3 TATB (0.285mol), add 8.8mL of formic acid HCOOH, 3mL of deionized water and 20mL of DEF, ultrasonically dissolve it fully, transfer it to a 100mL polytetrafluoroethylene-lined polyetheretherketone reactor, and put it in a microwave reactor for 10 Heated to 120°C within 1 minute and kept for 0min, centrifuged the white precipitated product, washed three times with DEF, absolute ethanol, and water respectively, and dried in vacuum at 75°C for 24 hours to obtain a metal organic layer material, specifically hafnium-based metal organic layer material.

Embodiment 3

[0046] A method for rapidly preparing metal-organic layer materials of the present invention, comprising the following steps:

[0047] Take 100mg zirconium chloride ZrCl 4 (0.438mmol) and 145mg 1,3,5-tris(4-carboxyphenylethynyl)benzeneH 3 BTE (0.285mmol), add 13mL HCOOH, 5mL deionized water and 25mL DMA, sonicate to fully dissolve, then transfer to a 100mL polytetrafluoroethylene-lined polyetheretherketone reactor, put it in a microwave reactor within 10 minutes Heat to 110°C and keep for 10min, centrifuge the white precipitated product, wash three times with DMA, absolute ethanol, and water, and dry in vacuum at 75°C for 24h to obtain a metal-organic layer material, specifically a zirconium-based metal-organic layer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com