Industrial continuous production equipment for polycarbonate polyether polyol

A polyether polyol, polycarbonate technology, applied in chemical instruments and methods, chemical/physical processes, pressure vessels used in chemical processes, etc., can solve the problem of long reaction time polyols, no amplification effect, internal carbonate chain Low energy saving and other issues

Pending Publication Date: 2020-10-23

HANGZHOU POLY MATERIAL SCI & TECH CO LTD

View PDF14 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] The technical problem to be solved by the present invention is to provide a kind of industrialized continuous production equipment of polycarbonate polyether

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

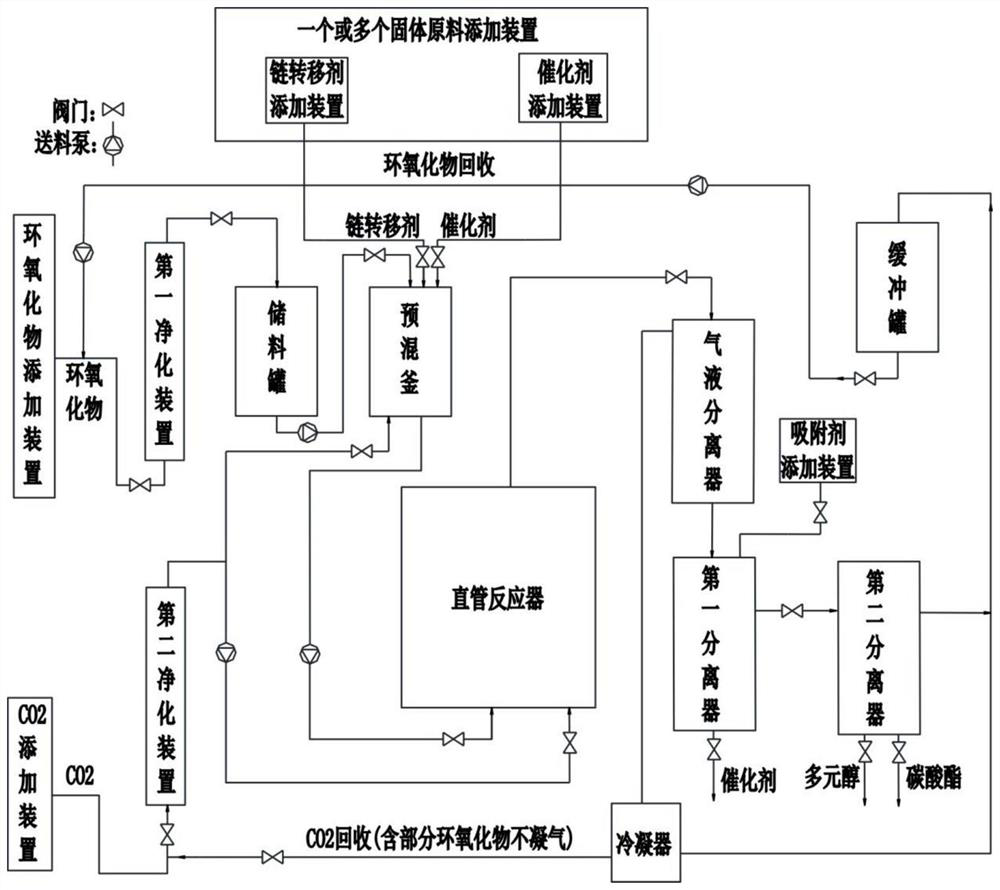

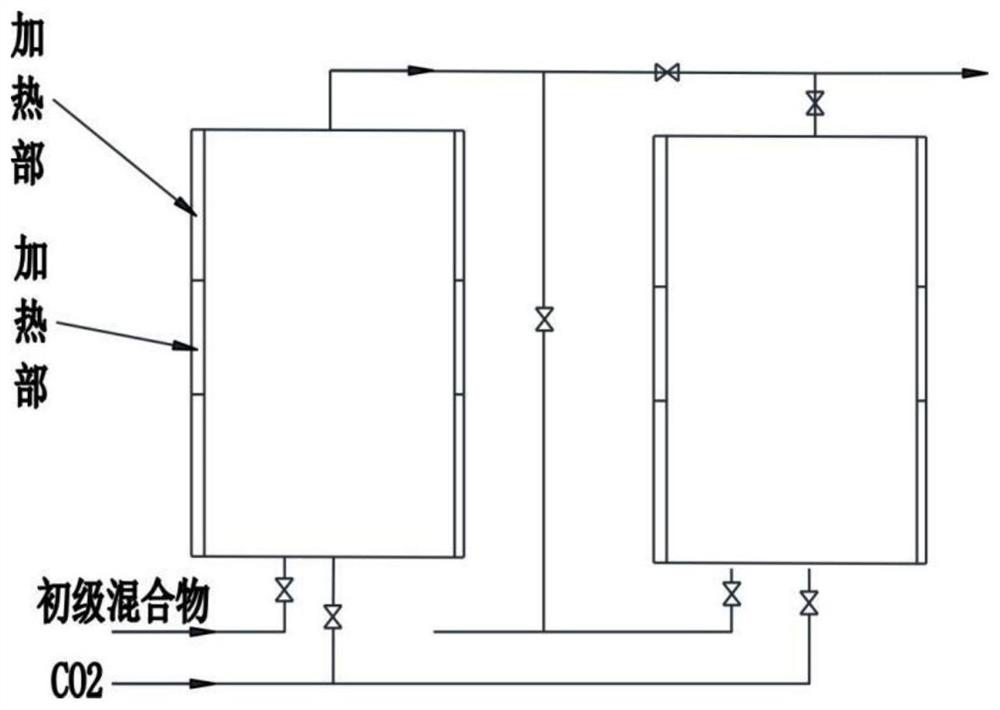

The invention provides industrial continuous production equipment for polycarbonate polyether polyol. The industrial continuous production equipment comprises a CO2 adding device, an epoxide adding device, a chain transfer agent adding device, a catalyst adding device, a premixing kettle and a straight-tube reactor; the premixing kettle is used for mixing epoxide, a chain transfer agent, a catalyst and low-pressure CO2 to form a primary mixture, and enabling the primary mixture to be in a to-be-reacted state; the straight-tube reactor is used for mixing the primary mixture and high-pressure CO2 to form a secondary mixture and enabling the secondary mixture to be in a synthetic reaction state; a straight-tube accommodating cavity is formed in the straight-tube reactor, a reaction mixing device is arranged in the straight-tube accommodating cavity, and the bottom of the straight-tube reactor is communicated with the premixing kettle and the CO2 adding device; a feeding pump used for pumping the primary mixture from the bottom of the straight-tube reactor is further connected between the premixing kettle and the straight-tube reactor, and the straight-tube reactor is vertically or obliquely arranged. According to the industrial continuous production equipment, the amplification effect can be avoided or relieved, and the reaction time is shortened.

Description

technical field [0001] The invention relates to the production technology of polycarbonate polyether polyol, in particular to an industrial continuous production equipment of polycarbonate polyether polyol, especially an industrial continuous production equipment without amplification effect. Background technique [0002] Since the industrial revolution, the extensive use of fossil energy has caused carbon dioxide emissions to increase year by year, and environmental pollution has become more and more serious. As a rapidly developing China, it is inseparable from the extensive use of fossil energy, and the situation of emission reduction is not optimistic. Plants use photosynthesis to absorb carbon dioxide and release oxygen, which is an environmentally friendly way, but the effect is slow. Humans can use chemical reactions to quickly achieve large amounts of consumption. [0003] Polycarbonate polyether polyols are formed by polymerizing carbon dioxide and epoxy compounds,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01F13/10B01J8/08B01J3/04B01F15/06C08G64/20C08G64/34

CPCB01J8/087B01J3/042C08G64/205C08G64/34B01J2208/00212B01F33/80B01F33/8362B01F2035/99B01F35/92B01F2101/2204

Inventor 毛红兵王慧君李俊巧

Owner HANGZHOU POLY MATERIAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com