Poultry feeding device for livestock breeding

A technology for poultry and food boxes, which can be used in poultry farming, animal husbandry, applications, etc., and can solve problems such as feed waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

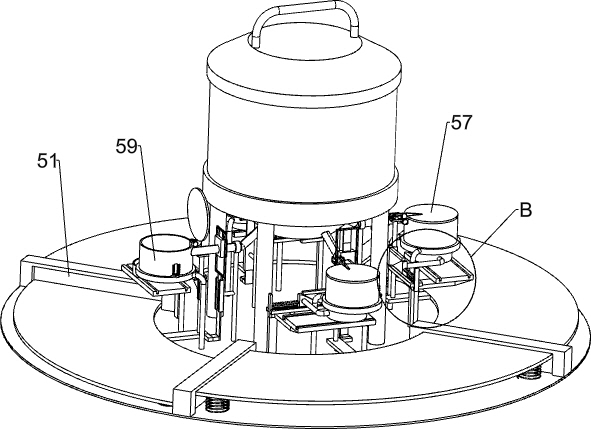

[0026] A poultry feeding device for animal husbandry, such as Figure 1-3 and Figure 5 As shown, it includes a bottom plate 1, a mounting frame 2, a storage tank 3, a bucket cover 4, a food box mechanism 5 and a feeding mechanism 6, the top of the bottom plate 1 is connected with a mounting frame 2, and the mounting frame 2 is connected with a storage tank 3. A bucket cover 4 is placed on the top of the storage barrel 3, a food box mechanism 5 is installed on the top of the bottom plate 1 outside the installation frame 2, and a feeding mechanism 6 is installed between the food box mechanism 5 and the storage barrel 3.

[0027] The food box mechanism 5 includes a fixed guide block 51, a pressing plate 52, a support spring 53, a first connecting plate 54, a first connecting rod 55, a sleeve 56, a cover frame 57, a connecting seat 58, a feed box 59 and the first fixed frame 510, the bottom plate 1 top on the outside of the mounting frame 2 is connected with a plurality of fixed...

Embodiment 2

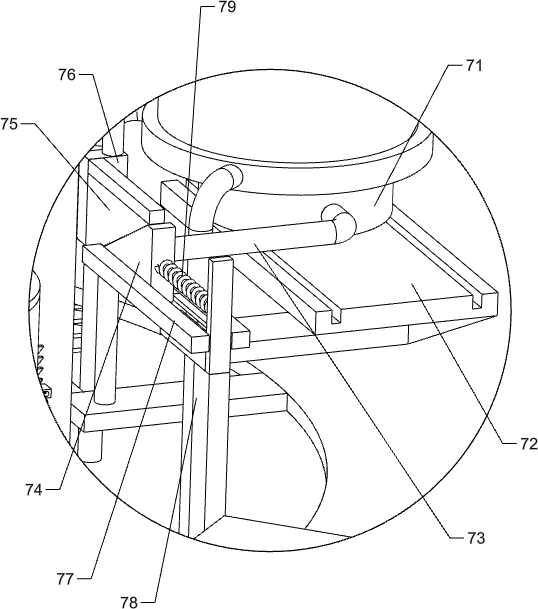

[0031] On the basis of Example 1, such as Image 6 As shown, a water box mechanism 7 is also included, and the water box mechanism 7 includes a water storage box 71, a track plate 72, a second connecting rod 73, a first wedge block 74, a second wedge block 75, a connecting block 76, and a fixed guide rail Frame 77, support frame 78 and first back-moving spring 79, bottom plate 1 top of fixed guide block 51 inner sides is connected with support frame 78, and support frame 78 top is connected with fixed guide rail frame 77, and fixed guide rail frame 77 bottom is connected with track plate 72, The first wedge-shaped block 74 is slidably connected in the fixed guide rail frame 77, and the first back-moving spring 79 is connected between the first wedge-shaped block 74 and the support frame 78, and the second connecting rod 73 is connected on the first wedge-shaped block 74. Connecting rod 73 is connected with water storage box 71, and water storage box 71 is connected with track ...

Embodiment 3

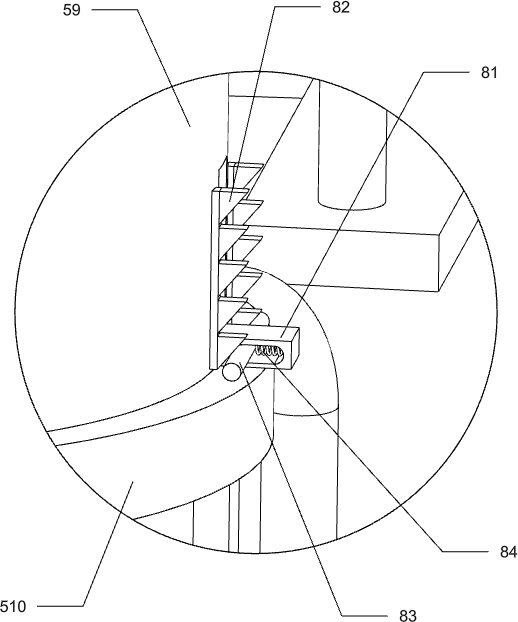

[0034] On the basis of Example 2, such as Figure 4 and Figure 7 As shown, it also includes a charging amount regulating mechanism 8, and the charging amount regulating mechanism 8 includes a sliding plate 81, a positioning card rack 82, a positioning rod 83 and a second return spring 84, and the feed box 59 is slidably connected with a sliding Plate 81, on the slide plate 81, the sliding type is connected with positioning bar 83, is connected with the second return spring 84 between positioning bar 83 and sliding plate 81 inner surfaces, and feed box 59 outer wall bottoms are connected with two positioning card racks 82, positioning The locking rack 82 cooperates with the positioning rod 83 .

[0035] The positioning rod 83 can be manually moved outward, and the second return spring 84 is compressed thereupon, and then the positioning rod 83 can be moved upward to move the sliding plate 81 upward. When the sliding plate 81 moves upward to a suitable position, it stops movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com