Molded article, sheet, and container, and tubular body, straw, swab, and balloon stick

A technology of formed body and tubular body, which is applied in the field of straws, cotton swabs and balloon rods, and can solve the problems of impact resistance, poor puncture resistance, low biodegradability, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0223] Hereinafter, specific embodiments of the present invention will be described in more detail using examples, but the present invention is not limited to the following examples unless the gist thereof is exceeded. In addition, the values of various manufacturing conditions and evaluation results in the following examples have the meaning of preferred values as the upper limit or lower limit of the embodiment of the present invention, and the preferred range may also be the value of the above upper limit or lower limit and the following The value of the examples, or the range specified by the combination of the values of the examples.

[0224] [Measurement of melt flow rate (MFR) of resin used]

[0225] Based on JIS K7210 (1999), it measured at 190 degreeC and the load of 2.16 kg using the melt indexer. The unit is g / 10 minutes.

[0226] [use raw materials]

[0227] Details of the resins and inorganic fillers used in Examples and Comparative Examples are as follow...

Embodiment I-1、 comparative example I-1~3

[0269] Mix the raw materials shown in Table 1 in the ratio shown in Table 1, and mix with the screw diameter at 140°C The twin-screw extruder is extruded into strips, and pelletized by a granulator. The diameter of screw used for the obtained resin pellets A single-screw extruder using a coat hanger-type T-die with a width of 300 mm was used, and the pulling speed was adjusted at 150° C. so that the film thickness was 100 μm to obtain a sheet. The cooling temperature was set to 50° C., and a semi-mat type and an air knife were used as cooling rolls. The obtained sheet was subjected to measurement of water vapor transmission rate and oxygen transmission rate and a biodegradability test. The results are shown in Table 1.

[0270] [Table 1]

[0271] (Table 1)

[0272]

[0273] From Table 1 we can know the following content.

[0274] Comparative Example I-1, which does not contain the inorganic filler (C), has poorer water vapor barrier properties than Example I-1. Lik...

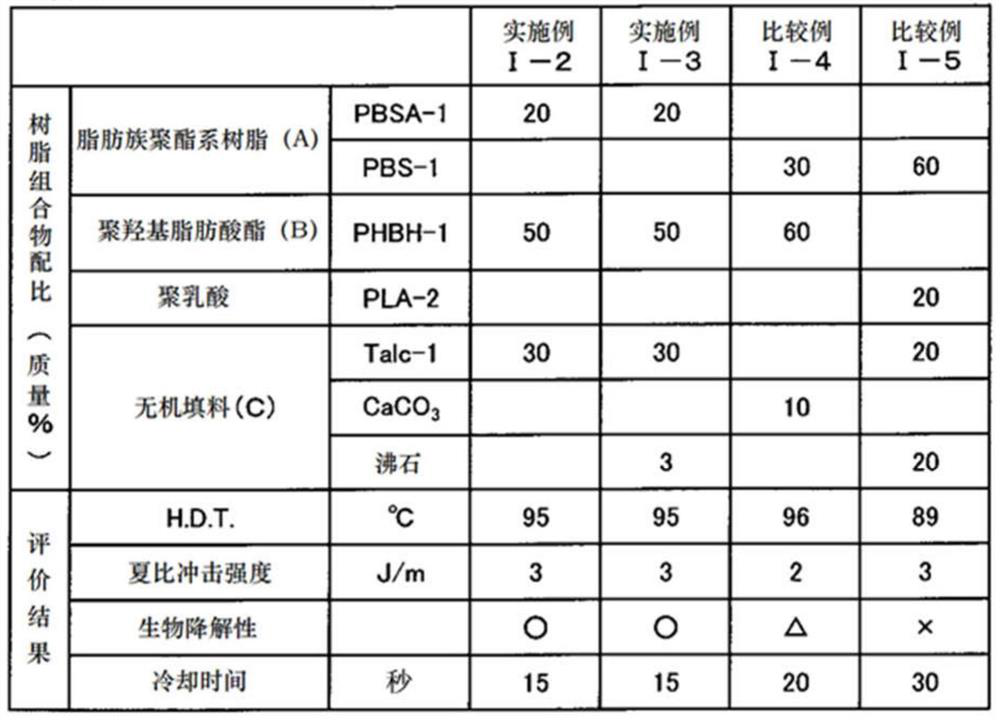

Embodiment I-2~3、 comparative example I-4~5

[0277] Mix the raw materials shown in Table 2 in the ratio shown in Table 2, and mix with the screw diameter at 140°C The twin-screw extruder is extruded into strips, and pelletized by a granulator. The obtained resin pellets were injection-molded at a mold temperature of 40° C. and a cylinder temperature of 150° C. to obtain ISO test pieces for mechanical property tests. For the obtained test piece, Charpy impact strength and H.D.T. measurement and biodegradability test were performed. The results are shown in Table 2.

[0278] The cooling time during injection molding is also described in Table 2. The cooling time is an index of formability, and the shorter the cooling time, the better the formability.

[0279] [Table 2]

[0280] (Table 2)

[0281]

[0282] As can be seen from Table 2, the heat resistance of Examples 1-2 and 3 containing aliphatic polyester resin (A), polyhydroxyalkanoate (B) and inorganic filler (C) within the prescribed range of the first inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com