Linear motor and three-degree-of-freedom planar motion platform

A technology of linear motor and planar motion, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as low efficiency, complex structure, long design cycle and delivery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

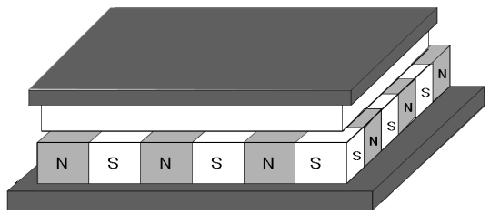

[0044] see Figure 11 and Figure 12 As shown, a linear motor, the linear motor includes a coil and a magnet, and the coil and the magnet are offset and positioned according to a certain offset distance D, so that the mover of the linear motor can be positioned relative to the linear The stator of the motor moves in a direction perpendicular to the driving direction of the linear motor.

Embodiment 2

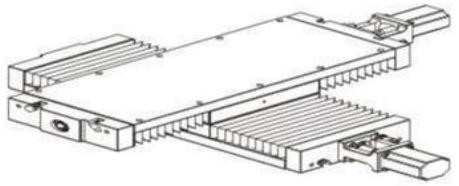

[0046] see Figure 4 , Figure 5 As shown, a three-degree-of-freedom planar motion table includes a relatively movable platform stator 1 and a platform mover 2, and four linear motors (see Embodiment 1) are arranged on the platform stator 1, respectively First, second, third and fourth linear motors 301, 302, 303, 304, the first and second linear motors 301, 302 are arranged oppositely, and the third and fourth linear motors 303, 304 are arranged oppositely , the platform mover 2 is located in the area formed by the first, second, third and fourth linear motors 301 , 302 , 303 , 304 .

[0047] Further, the magnet parts of the first, second, third and fourth linear motors 301, 302, 303, 304 are fixed on the platform stator 1, and the first, second, third and fourth The coils of the linear motors 301 , 302 , 303 , 304 are fixed on the platform mover 2 .

[0048] Further, an air bearing 4 is provided between the platform stator 1 and the platform mover 2 .

[0049] Further, t...

Embodiment 3

[0052] see Figure 6 , Figure 7 As shown, a three-degree-of-freedom planar motion table includes a relatively movable platform stator 1 and a platform mover 2, and four linear motors (see Embodiment 1) are arranged on the platform stator 1, respectively. 1. The second, third and fourth linear motors 301, 302, 303, 304, the first and second linear motors 301, 302 are arranged oppositely, and the third and fourth linear motors 303, 304 are arranged oppositely, The platform mover 2 is located in the area formed by the first, second, third and fourth linear motors 301 , 302 , 303 , 304 .

[0053] Further, the coil parts of the first, second, third and fourth linear motors 301, 302, 303, 304 are fixed on the platform stator 1, and the first, second, third and fourth The magnet parts of the linear motors 301 , 302 , 303 , 304 are fixed on the platform mover 2 .

[0054] Further, an air bearing 4 is provided between the platform stator 1 and the platform mover 2 .

[0055] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com