Integrated ceramic ferrule and optical fiber socket

A ceramic ferrule, integrated technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of buffer protection channel metal part difference, high strength requirements of ceramic ferrule, high risk of problems, etc., to achieve temperature change stress reduction , Reliable product performance, Avoid possible effects of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

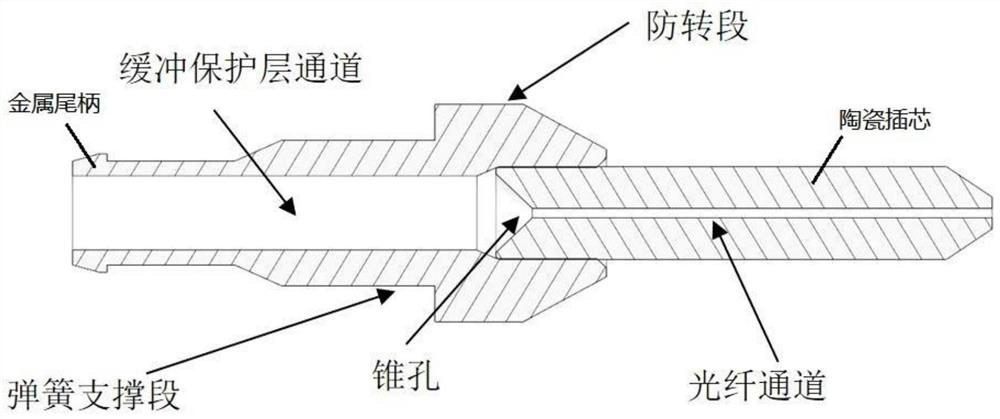

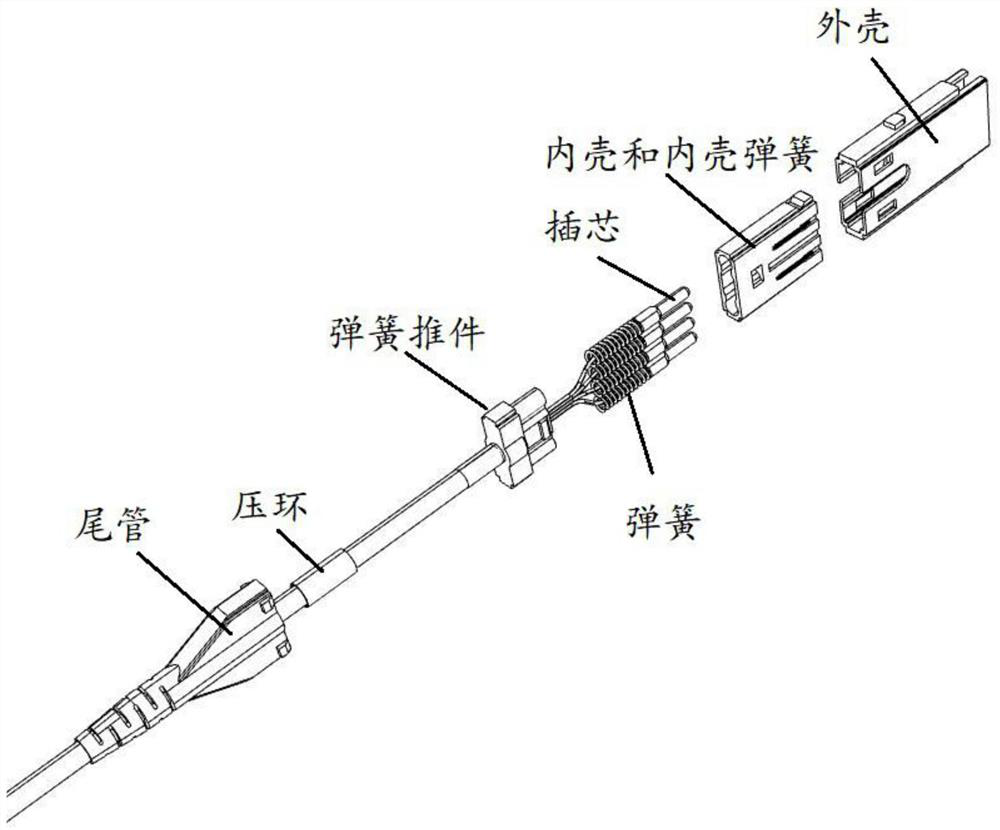

[0031] In conjunction with the accompanying drawings and embodiments, the technical solution adopted in the present invention will be further described,

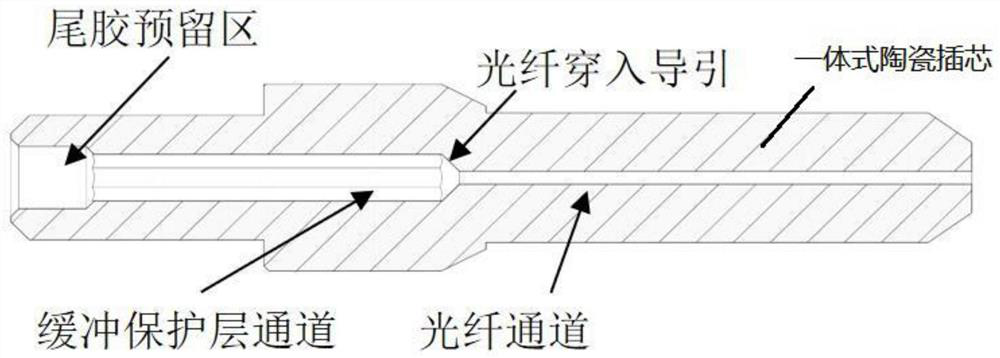

[0032] The present invention provides an integrated ceramic ferrule such as figure 2 As shown, the buffer protection layer channel originally in the metal tail handle is moved to the ceramic ferrule, and the anti-rotation and spring support structures are directly provided on the ceramic ferrule.

[0033] The front section of the inner hole of the integrated ceramic ferrule is a fiber channel for fixing the optical fiber, and there is a fiber penetration guide section at the end of the fiber channel.

[0034] The rear section of the inner hole of the integrated ceramic ferrule is a buffer layer protection channel for fixing the optical fiber buffer protection layer. And there is a tail glue area at the end to strengthen the protection of the optical fiber.

[0035] There is an anti-rotation structure on the outer edge str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com