Automatic furnace pressure adjustment mechanism for low-temperature pure oxygen combustion aluminum melting furnace and adjustment method

A technology for automatic adjustment and melting of aluminum furnaces, applied in furnaces, crucible furnaces, furnace types, etc., and can solve problems such as slow execution speed, sudden increase, and failure of pressure adjustment systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The core of the present invention is to provide a furnace pressure automatic adjustment mechanism and adjustment method for a low-temperature pure oxygen combustion aluminum melting furnace. Using the furnace pressure automatic adjustment mechanism can quickly and efficiently stabilize the pressure in the aluminum melting furnace at 1-20Pa.

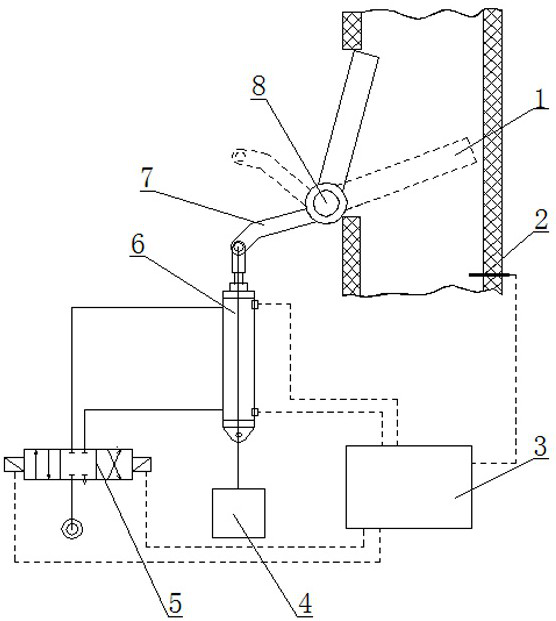

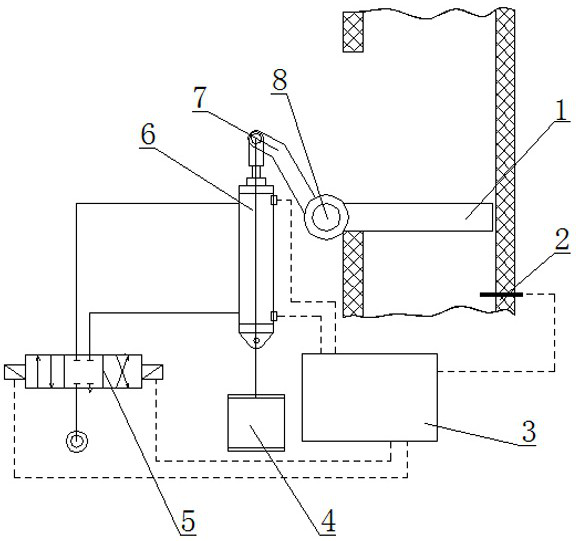

[0024] A furnace pressure automatic adjustment mechanism for a low-temperature pure oxygen combustion aluminum melting furnace, which adjusts the furnace pressure by means of a flue arranged outside the aluminum melting furnace and communicated with the furnace through the smoke exhaust port. Please refer to figure 1 with figure 2 The furnace pressure automatic adjustment mechanism includes a gate 1, a lever 7, a balance weight 4, a cylinder 6, a pressure sensor 2, a solenoid valve 5 and a controller 3; one end of the lever 7 is sleeved on a support outside the flue On the shaft 8 and can rotate around the support shaft 8, a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com