Lifting device and application method thereof

A technology for lifting devices and lifting brackets, which is applied in the direction of lifting devices, lifting frames, etc., and can solve the problems of too many auxiliary tools, non-compliance, and inability to do first-in-first-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

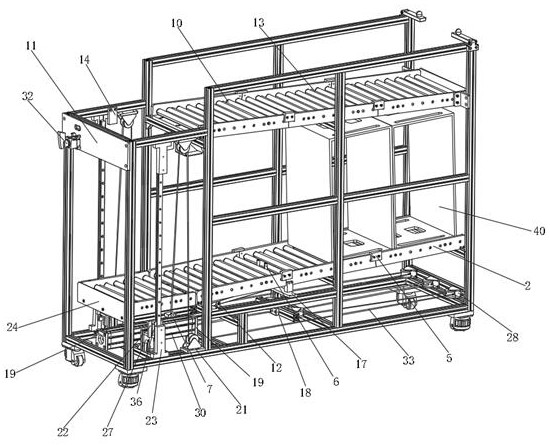

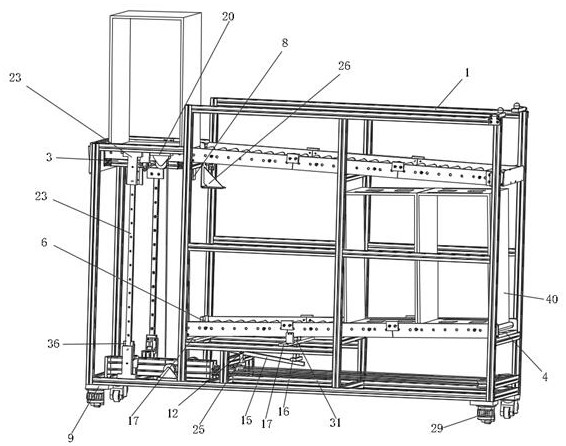

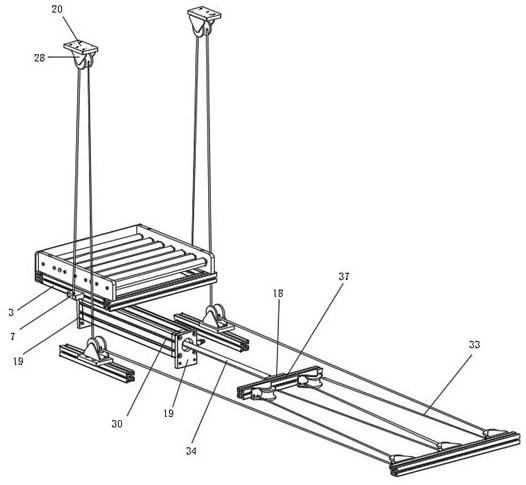

[0019] Such as Figures 1 to 3Shown, a kind of lifting device comprises frame 1, is divided into three layers in frame 1, and one side short side of bottom is provided with three transverse fixed pulleys 28, is provided with on the two crossbeams of frame 1 opposite to it. Two cylinder fixing plates 19 are fixed cylinder 30, and one end of cylinder piston rod 34 connects the inside of cylinder 30, and the other end of cylinder piston rod 34 connects cylinder connection block 18, and cylinder connection block 18 is fixed on the movable pulley block 37, and on the cylinder 30 The frame 1 on both sides of the long surface is provided with two lower pulley fixing plates 21 and is equipped with fixed pulleys 28, and the upper frame 1 opposite to the lower pulley fixing plates 21 is provided with two upper pulley fixing plates 20 and is equipped with fixed pulleys. The pulley 28 is provided with two height stops 14 on the left side of the two upper pulley fixed plates 20, and is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com