Integrally-formed lightweight cast cross beam assembly

A beam assembly and lightweight technology, applied in the field of chassis parts, can solve the problems of stress concentration, many stamped beam parts, and low torsional performance of stamped sheet metal beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

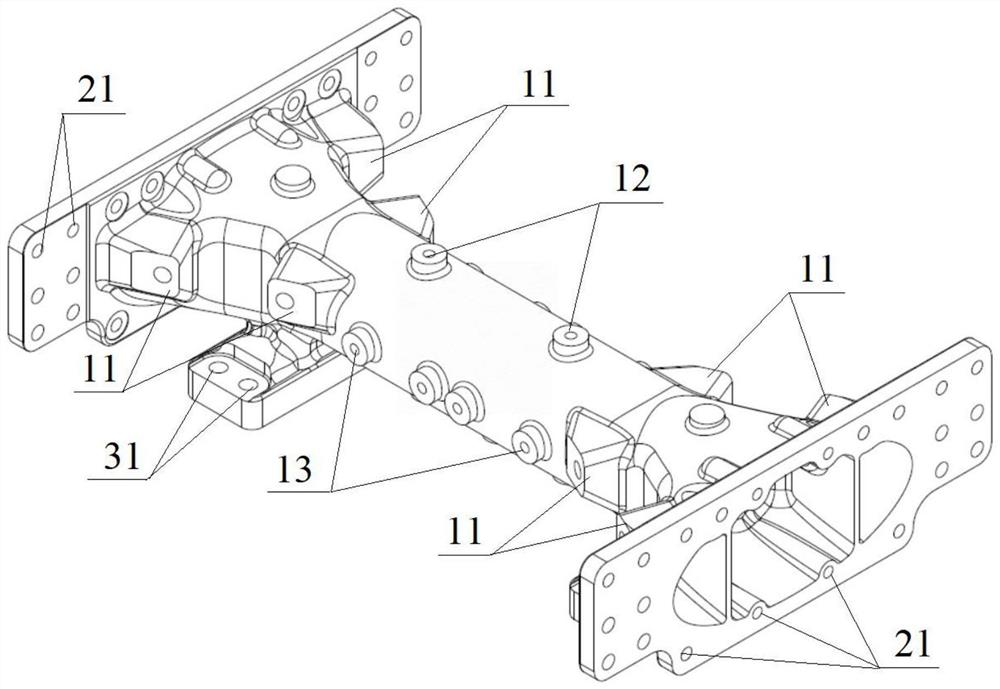

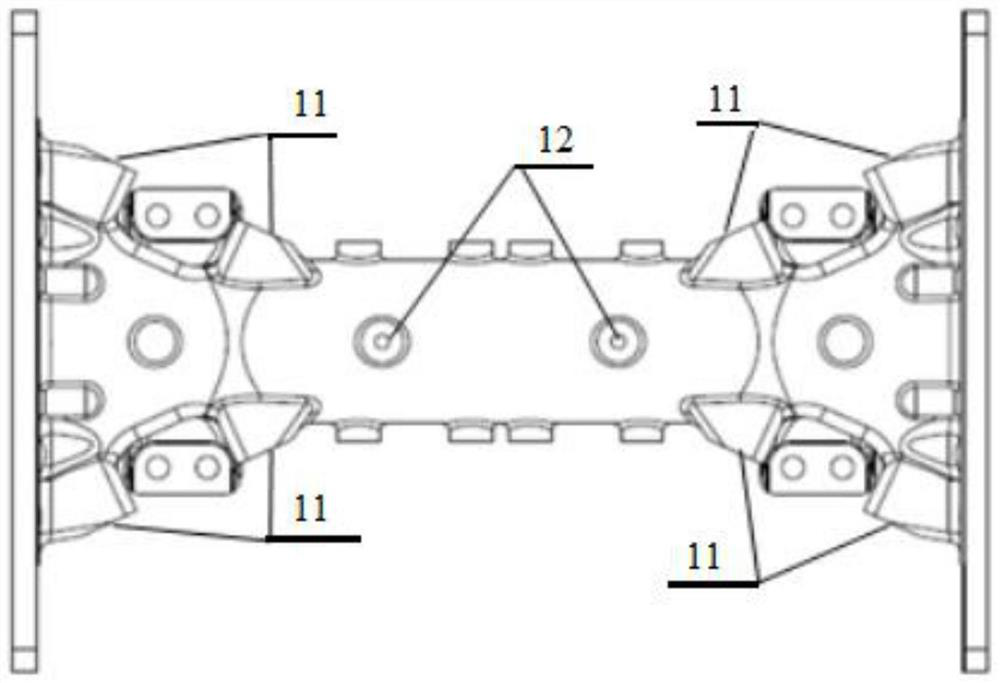

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] In order to improve the reliability of the crossbeam connection, ensure that the crossbeam can provide sufficient support rigidity to the vehicle frame after the bolts are tightened, and avoid the risk of cracking caused by the stress concentration of the stamped sheet metal crossbeam due to local connection points, the integrally formed light weight of the present invention The quantitative casting beam assembly provides a new beam structure, which reduces the weight of the beam assembly, improves the torsion resistance of the frame, improves the fuel economy of the product, and reduces the manufacturing cost of the vehicle; in addition, the beam assembly is cast in one piece, It can reduce the risk of cracking of the weak link and improve the torsional capacity of the beam assembly.

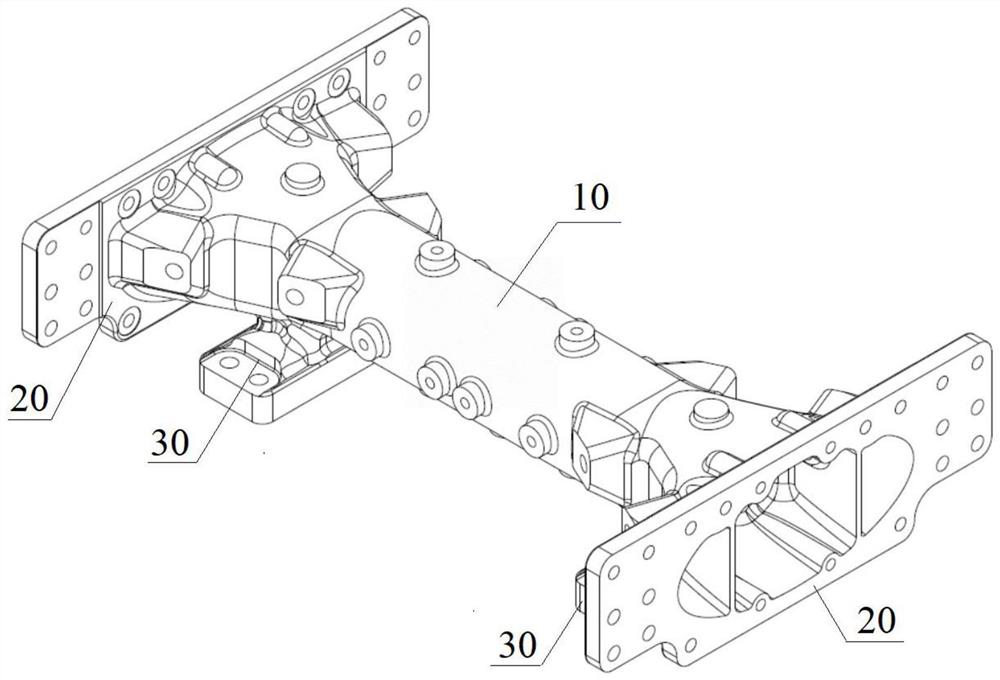

[0027] see figure 1 and figure 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com