Ink mist suction carried out by means of air humidity sensor

An air humidity and sensor technology, used in printing, rotary printing machines, printing machines, etc., can solve problems such as non-compliance with functional requirements, failure to be detected in time, and reduced performance of suction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

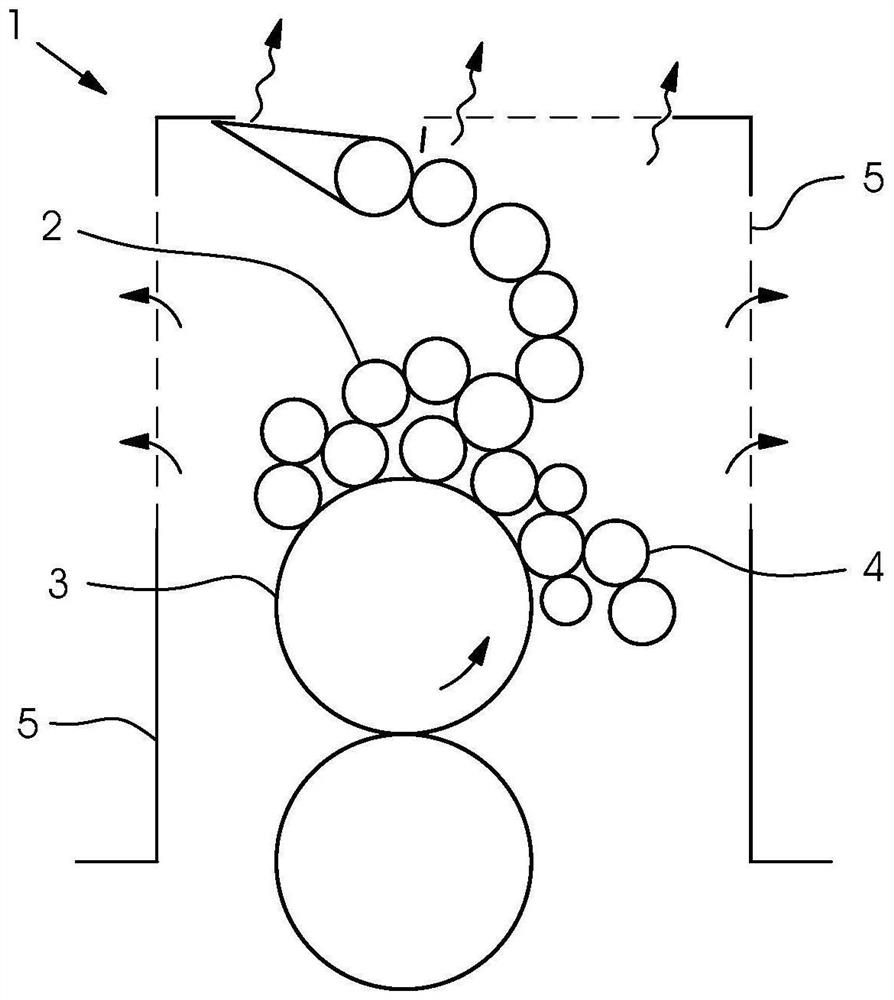

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

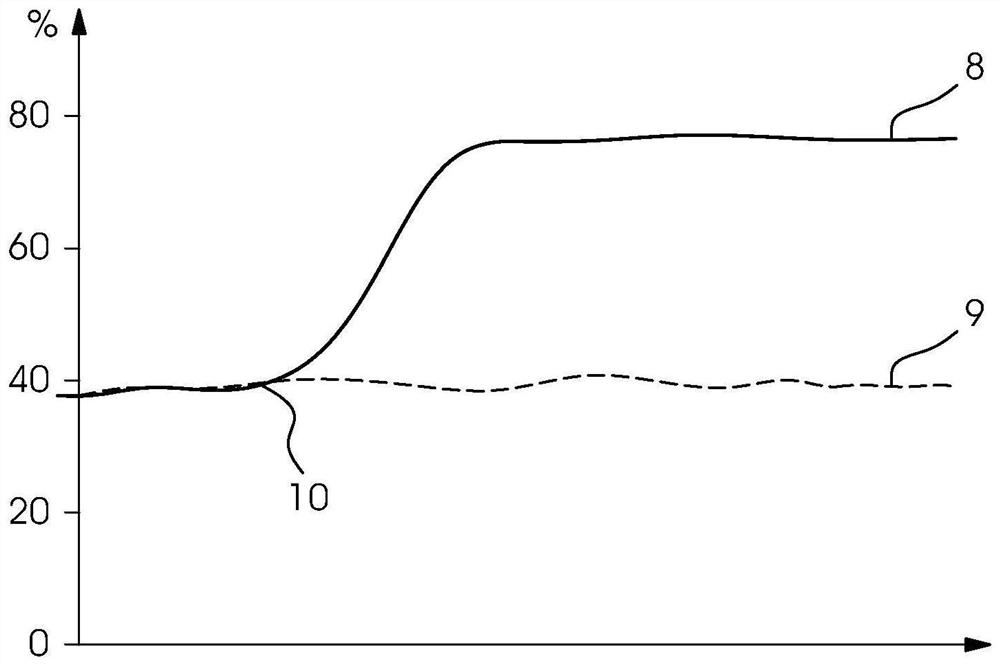

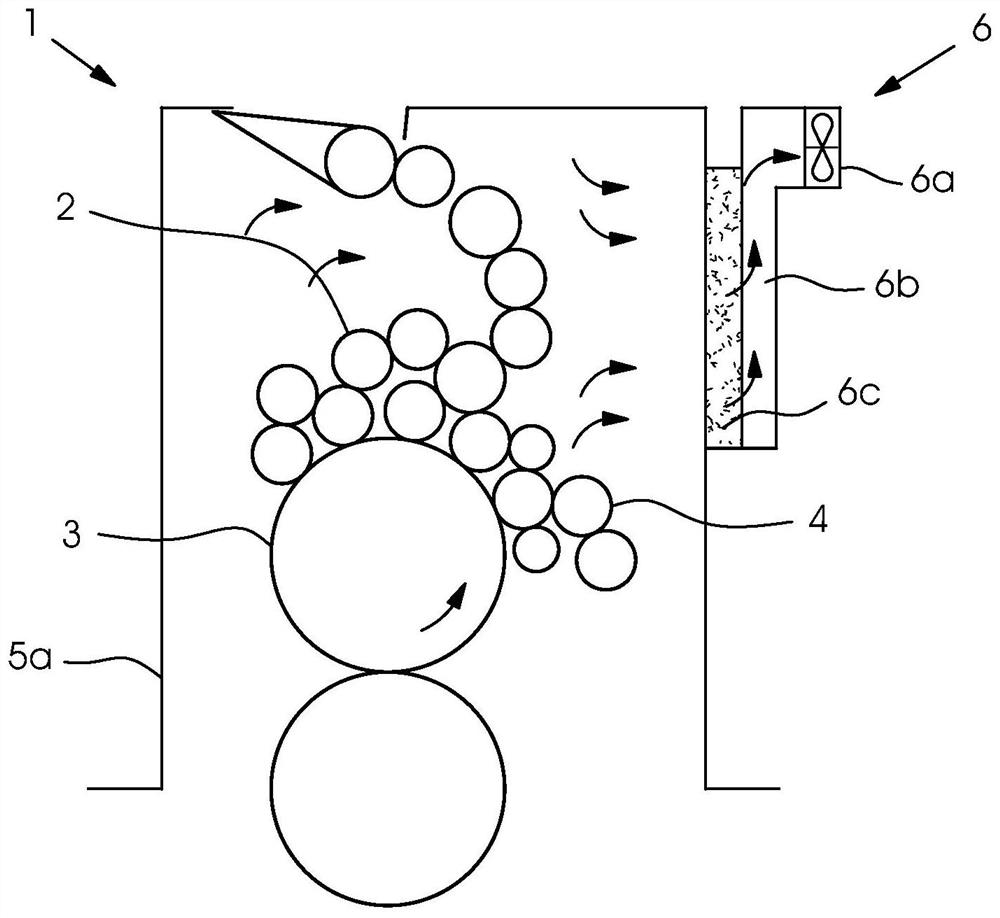

[0039] The basis of the invention is based on the experimental measurement knowledge that a significantly higher air humidity value 11 is present in a non-operating ink mist suction device 6 than the air humidity value 12 in normal operation. In the case of a damaged or poorly maintained suction device 6 , the suction performance is reduced and the ventilation of the printing unit 1 is considerably worse. Due to this poor ventilation, the air humidity values 11 , 12 in the printing unit 1 rise strongly.

[0040] The core of the invention therefore lies in the functional monitoring of the ink mist suction device 6 by means of the continuous monitoring of the relative air humidity 11 , 12 during the printing operation by means of the air humidity sensor 7 . The height of the measured values 11 , 12 is detected and evaluated accordingly. This enables computer-supported forecasting or trend analysis 21 in order to display limit value states 23 in good time.

[0041] Starting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap